3 - 31

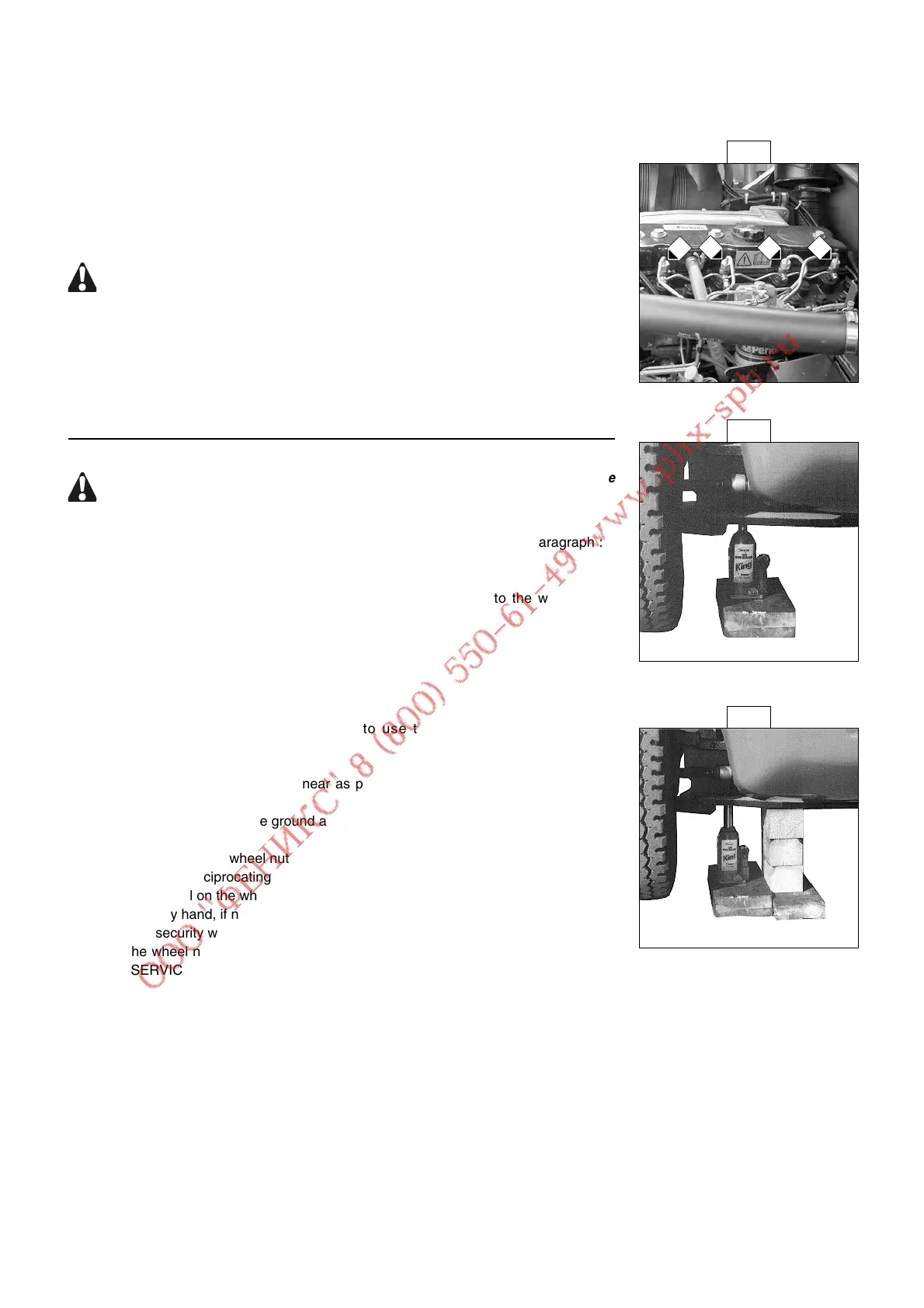

BLEEDING THE INJECTORS

- Loosen high pressure connectors 6 (Fig. G1/6) of two of the injectors.

- Activate the starter until the diesel fuel flows out free of air at connections 6 (Fig. G1/6).

- Tighten the connection while the diesel fuel is flowing out (Tightening torque 22 N.m).

- Reassemble the left side panel 1 (Fig. G1/1).

The I.C. engine is then ready to be started up.

Turn the I.C. engine over slowly for 5 minutes immediately after bleeding the fuel feed

circuit, in order to ensure that the injection pump has been bled thoroughly.

NOTE : If the I.C. engine functions correctly for a short time then stops or functions

irregularly, check for possible leaks in the low pressure circuit. If in doubt,

contact your dealer.

G2 - WHEEL

CHANGE

In the event of a wheel being changed on the public highway, make sure of the

following points :

- Stop the lift truck, if possible on even and hard ground.

- To pass on stop of lift truck (See chapter : DRIVING INSTRUCTIONS in paragraph : 1

- OPERATING AND SAFETY INSTRUCTIONS).

- Put the warning lights on.

- Immobilise the lift truck in both directions on the axle opposite to the wheel to be

changed.

- Unlock the nuts of the wheel to be changed.

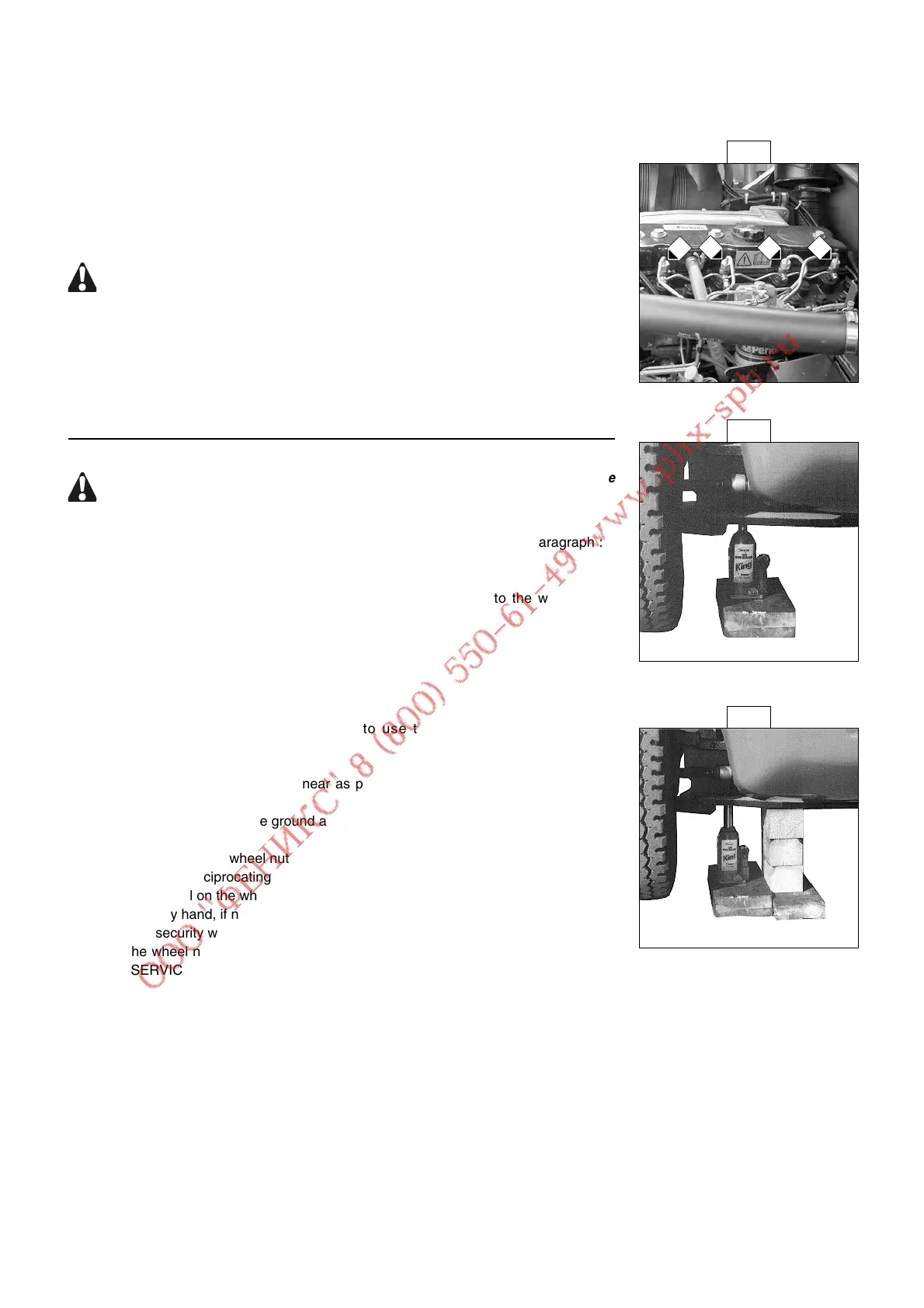

REAR WHEEL

NOTE : For this operation, we advise you to use the hydraulic jack MANITOU

Reference 505 507.

- Fit the jack under the rear axle, as near as possible to the wheel to be changed and

adjust the jack (Fig. G2/1).

- Lift the wheel until it lifts off the ground and fit security wedges under the rear axle (Fig.

G2/2).

- Completely unscrew the wheel nuts and remove them.

- Free the wheel by reciprocating movements and roll it to the side.

- Slip the new wheel on the wheel hub.

- Refit the nuts by hand, if necessary grease them.

- Remove the security wedges and lower the lift truck with the jack.

- Tighten the wheel nuts with a torque wrench (See chapter : A - DAILY OR EVERY 10

HOURS SERVICE in paragraph : 3 - MAINTENANCE for tightening torque).

G1/6

6

6

6 6

G2/1

G2/2

Loading...

Loading...