B5 – TENSION AND ALIGNMENT OF THE MAST LIFTING CHAINS

CHECK - ADJUST

IMPORTANT

These checks are important for the good working operation of the mast.

In case of technical faults, consult your dealer

Place the lift truck on level ground with the mast in a vertical position and the forks

lifted at approximately 200 mm.

- Check the alignment of the mast lifting chains between the carriage chain fasteners

and the chain rollers.

- With your hand verify the chain tension and, if necessary, adjust as indicated below

while ensuring that the carriage is perpendicular to the mast.

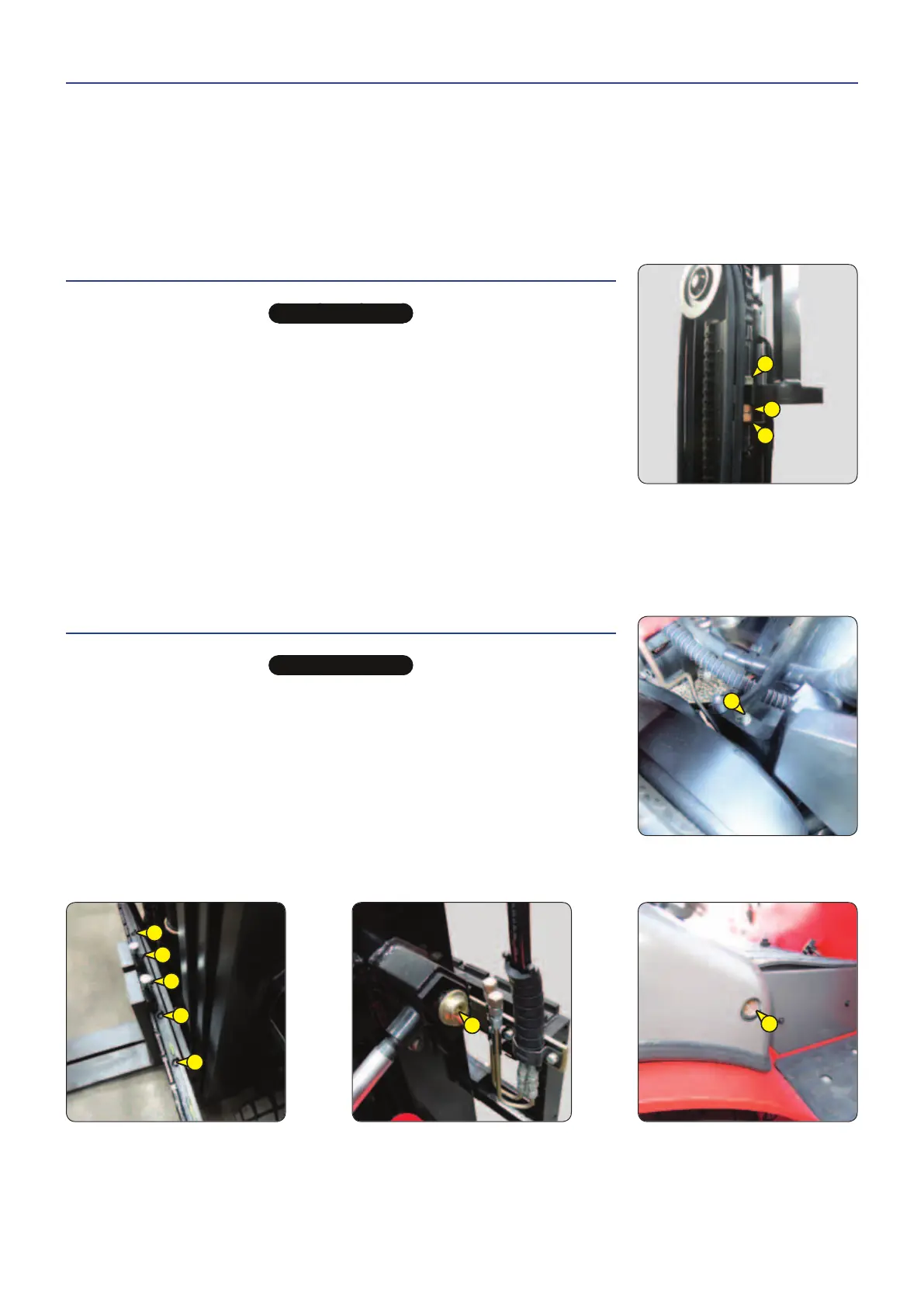

- Loosen nut 1.

- Loosen the chain tensioner lock nut (2).

- Adjust the tension by tightening or loosening the nut 3 while checking the alignment of the lifting chains.

- Then tighten lock nut (2) and nut (3).

- Re-tighten the nut 1.

B4 – WHEEL NUT TIGHTENING

CHECK

- Check the condition of the tyres, to detect cuts, blisters, wear, etc.

- Check the wheel nut tightening torques. Failure to comply with this instruction may lead to damage and failure of the

wheel studs and distortion to the wheels.

Tightening torque of wheel nuts: Front wheels 441 to 558 N.m

Rear wheels 157 to 176 N.m

NOTE: There is an OPTIONAL wheel toolkit.

B6 – MAST

GREASE

IMPORTANT

In the event of prolonged use in an extremely dusty or oxidizing atmosphere,

reduce this interval to every 10 hours of service or every day.

To be carried out weekly, if the lift truck has been operated for less than 50 hours during

the week.

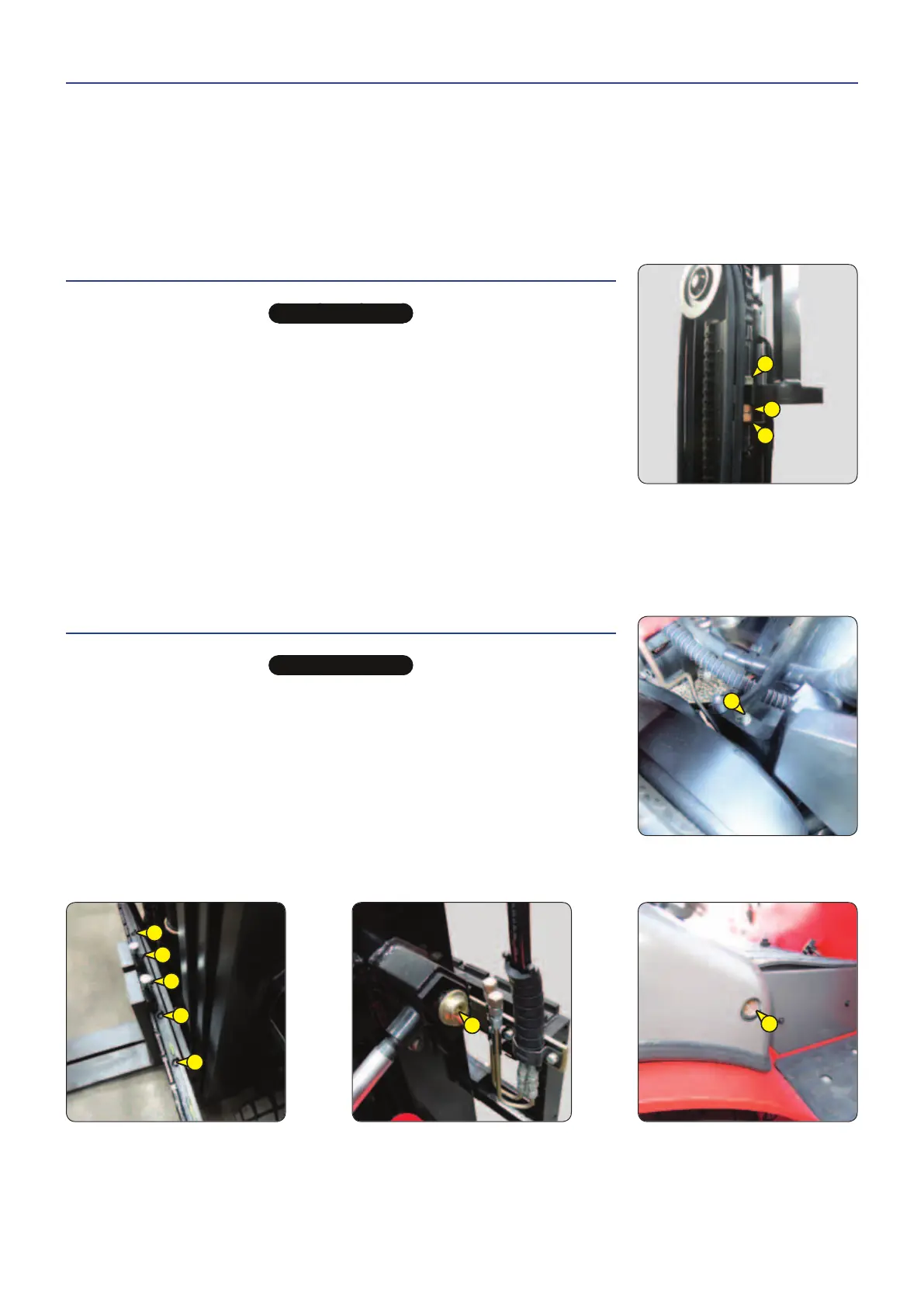

- Clean and lubricate the following points with grease (see: 3 - MAINTENANCE:

LUBRICANTS) and remove the surplus of grease.

• 1 - Lubricators of the articulation axles at the foot of the mast (2 lubricators).

• 2 - Lubricators of the tilt cylinder head axles (2 lubricators).

• 3 - Lubricators of the tilt cylinder head axles (2 lubricators).

• 4 - Lubricators of the side-shift carriage (5 lubricators).

3-13

3

2

1

1

4

4

4

4

4

3

2

647503 (10/05/2017)

E 418/420/425C 48V S3

Loading...

Loading...