Section 3 Operation

Part Number 020003315 1/11 3-3

ROCKING CHUTE ICE DISPENSING

On units without the selectable ice option, as the

customer presses the rocking chute, the arm at the top

left rear of the chute pushes upward on the door lock.

The door opens until it contacts the stops in the

mounting brackets. The plastic arm on the ice chute also

activates the lever of the ice dispensing switch. When

activated, the micro switch starts the gear motor. The

gear motor turns the paddle wheel and agitator bar.

SELECTABLE ICE SEQUENCE OF OPERATION

On units equipped with the selectable ice option, as a

customer presses the ice chute or pushes the sanitary lever

towards the unit with their cup, with “Crushed Ice” selected

on the ice selection pad, the rocking chute door lifts and

actuates micro switch which initiates the crushed ice

dispensing process. The micro switch is activated when the

lever is approximately 1/4 inch from reaching the splash

panel of the unit. When activated, the micro switch starts the

gear motor and ice crusher motor. The gear motor turns the

paddle wheel and U-bar agitator. The paddle wheel carries

ice to the crusher assembly. Once the ice reaches the

crusher housing, four stationary blades and three rotating

blades crush the ice and push it through the opening in the

ice crusher housing. The crushed ice then falls through the

opening into the ice chute, and into the customer’s cup. If the

merchandiser is removed no power is available to the

crusher or gear motor and no ice can be crushed and/or

dispensed.

CARBONATION

The purpose of the carbonator is to take regular tap

water at street water pressure (minimum 20 PSI,

maximum 80 PSI, dynamic or flowing pressure) 1/2"

water line and increase the water to beverage system

pressure (usually 100 PSI). This water is then combined

with the CO

2

gas. Because the water and gas are at the

same pressure, the CO

2

will dissolve into the water.

Chilling the mixture before dispensing will assist in

locking the carbon dioxide into the water. After

dispensing, the CO

2

may be unlocked from the liquid.

The CO

2

will gradually leave the liquid due to pressure

and temperature changes.

Components

The components of the carbonator are: water pump, an

electric motor to operate the pump, carbonator tank

where the water and CO

2

mix, and a water level control.

Operation

Carbon Dioxide (CO

2

) leaves the storage tank and

arrives at the carbonator tank through the gas inlet.

Water supply enters the carbonator pump inlet at regular

street water line pressure (minimum 20 PSI, maximum

80 PSI, dynamic or flowing pressure). The water pump

increases the pressure of the water, which allows the

water to flow into the carbonator tank. The CO

2

and the

water mix together in the carbonator to produce the

carbonated water that is then sent to the soda dispenser.

The agitation of the water and CO

2

together in the tank

under high pressure creates the soda water. The quality

of carbonation (percent of CO

2

mixed in the water)

increases as the water temperature decreases and

exposure time increases.

The water level in the carbonator tank is controlled by a

water level control in the tank. This control turns the

pump motor off and on to maintain a preset level of liquid

in the tank. The water level control may be electronic

probes or a mechanical float.

SYRUP DELIVERY SYSTEM

Your syrup location can vary depending on the volume of

beverages served and ease of accessibility. Your beverage

system may set in a back storage room or under the

counter of the dispenser. Configurations are almost

limitless. Check the temperatures expected for the storage

location. Adverse temperatures can affect the storage and

quality of beverage products. It is recommended the

temperature of storage location should not fall below 40°F

(4°C) or rise above 90°F (32°C).

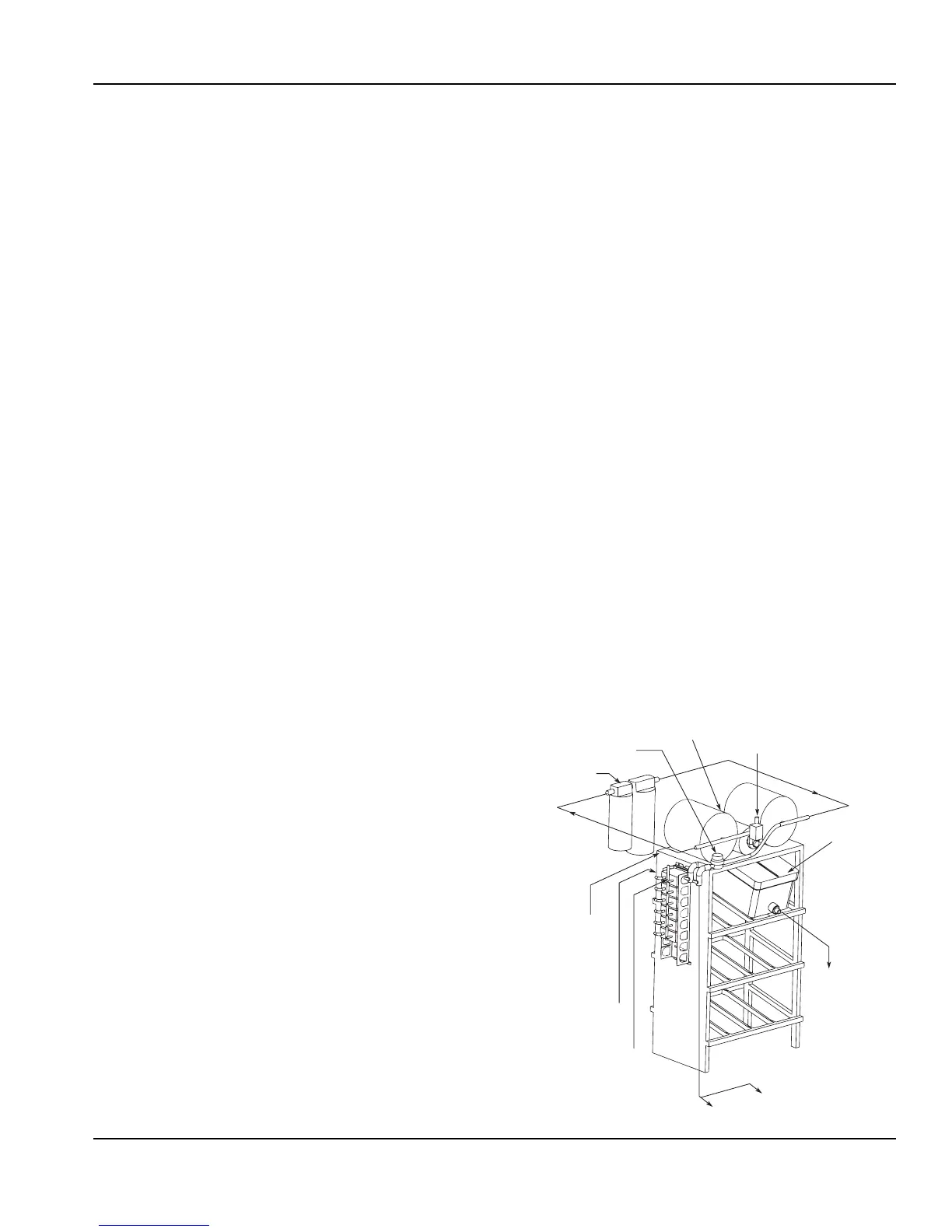

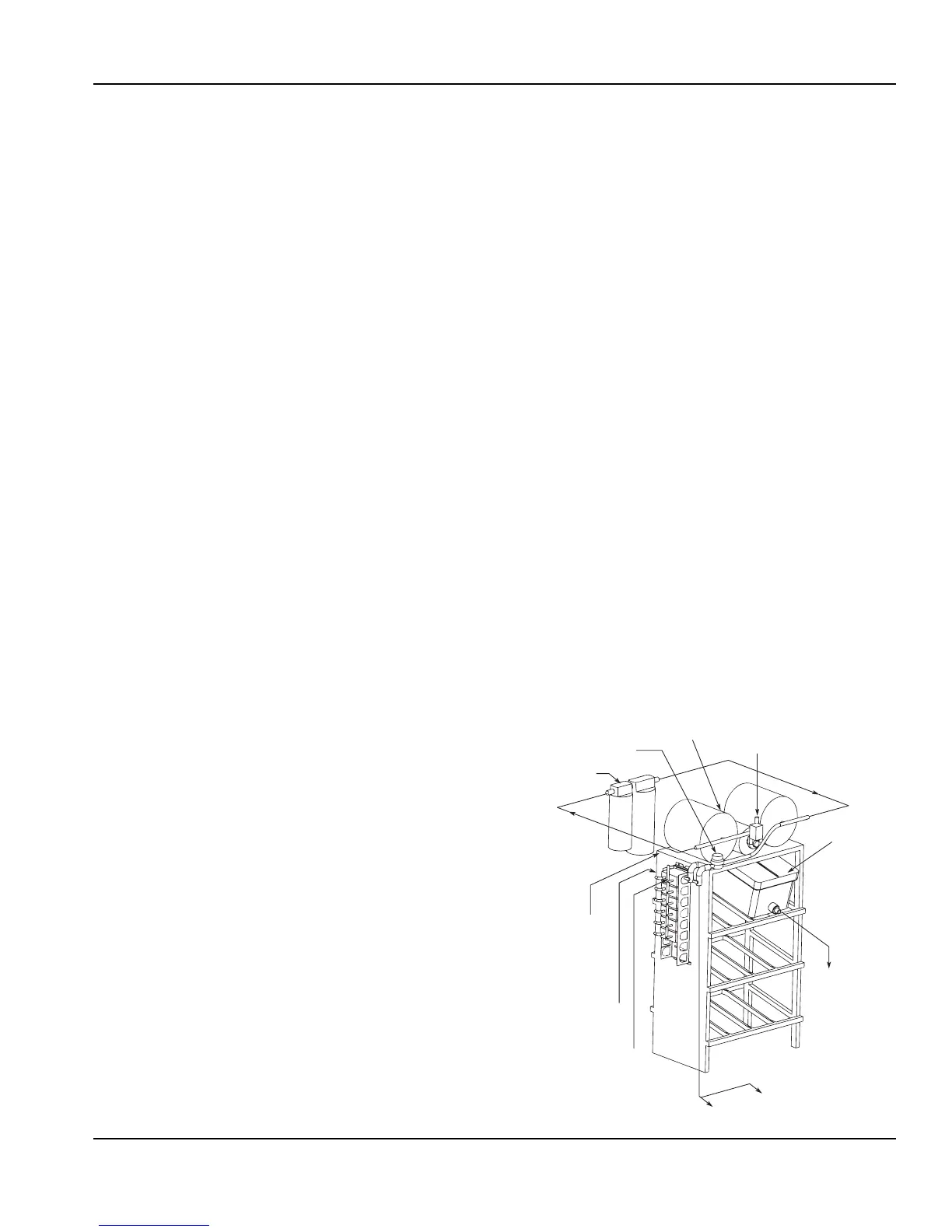

BACK ROOM PACKAGE

From Water Supply

To Noncarbonated Water Inlet Barb

Water to Carbonator Pump

Filter

Water Regulator 40–70 PSI

Booster System (If Required)

To CO

2

Manifold (BIB

Pumps) from

CO

2

Supply

70 PSI

To Syrup Inlet

Barbs on Unit

To BIB Pumps

from BIB

To BIB

Pump

BIB

Loading...

Loading...