4-8 Published 12-21-2011 CTRL #050-09

SET-UP 1300A OPERATOR’S MANUAL

NOTE: The torque must be rechecked after the initial

operation of the crane. Be sure the cable clamp is

attached to the dead end of the cable only.

7. Start winding the cable onto the hoist drum. Maintain

about 500 pounds (250 kg) of tension on the cable.

8. Keep the cable wraps tight against each other when the

first half of the bare hoist is filling. The second half of the

hoist should wrap tightly because the fleet angle of the

cable tends to pull the cable to the center of the drum

thus wrapping tightly.

9. Continue winding the cable on the second, third and

fourth layer of the hoist. Keep the cable paying in

straight to the boom to avoid side loading the boom. The

preceding layers will wrap smoothly guided by the first

layer wrapping.

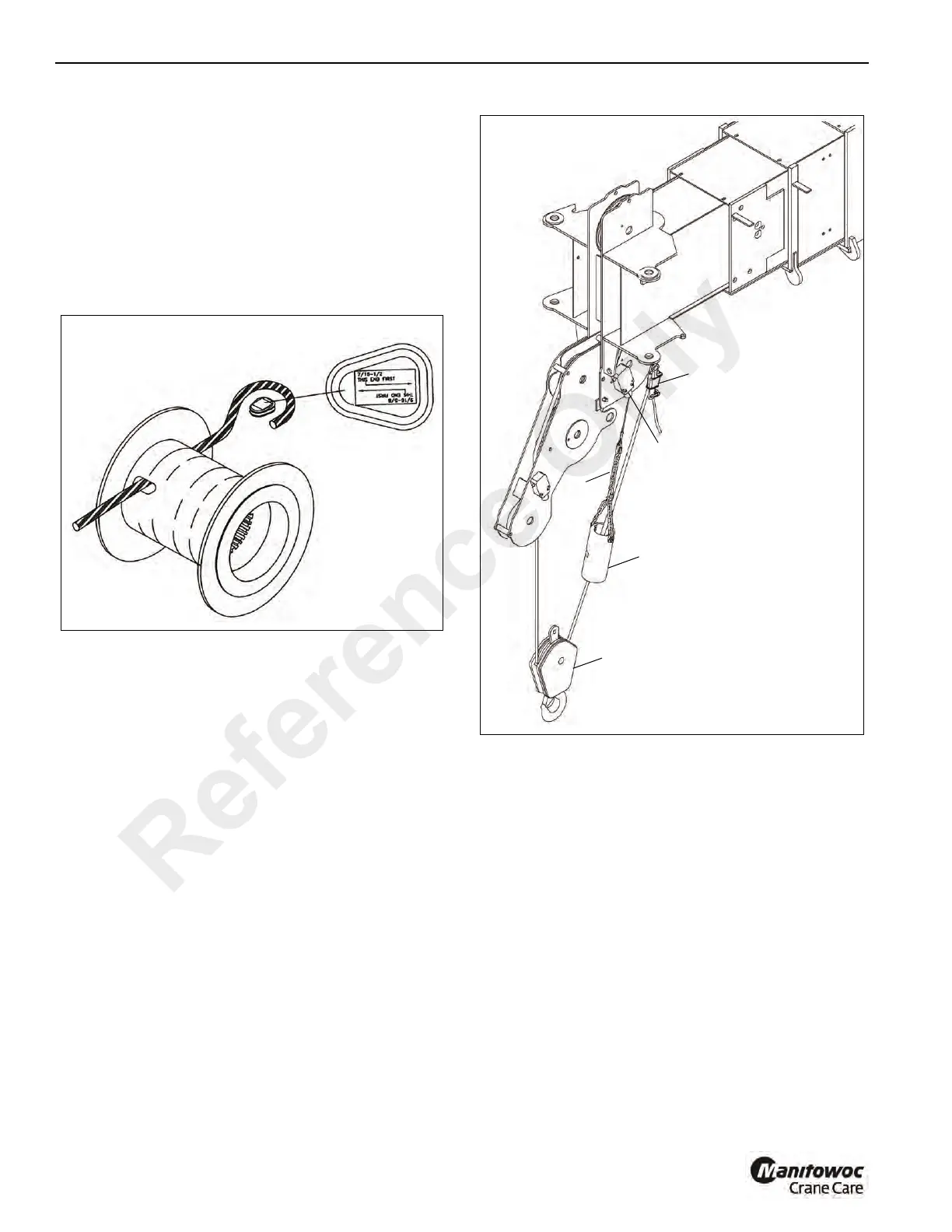

WIRELINE REEVING

Reeving for Wireline machines using a 2/3 line hook block is

shown in Figure 4-6. Install the Anti-2-block weight (1) on the

wedge socket (2) side of the hook block (3). Connect the

Anti-2-block chain (4) to the upper switch assembly (5).

WEDGE SOCKETS

To install a wedge socket:

• Make sure the wedge socket is the proper size for the

cable.

• Do not mix components of different wedge socket

manufacturers.

• The wedge socket must meet the requirements of the

wedge socket and wire rope manufacturers.

State and local laws may vary and require different

attachment methods depending upon work conditions. The

user is responsible for alternate attachment methods.

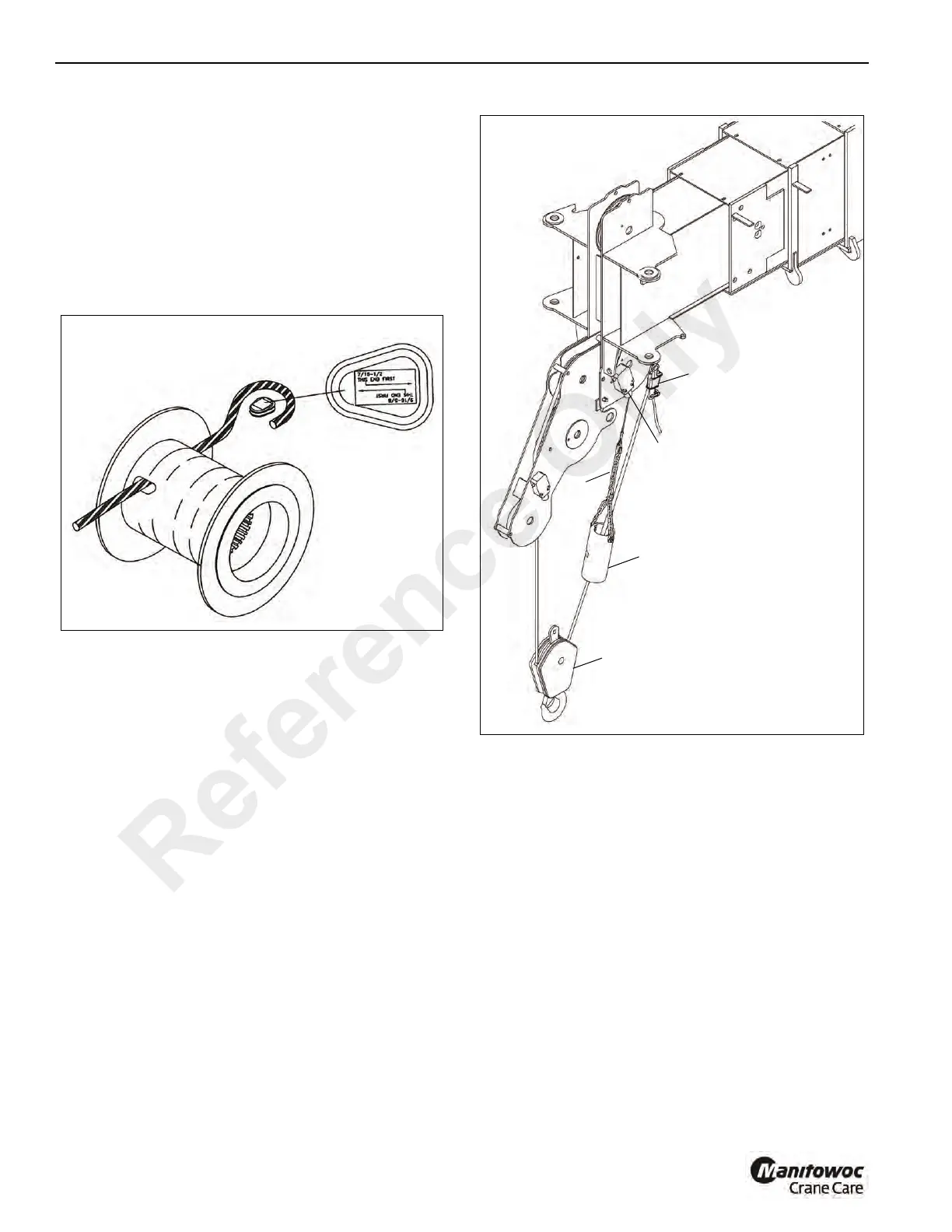

Terminator Wedge Installation

The 1300A is shipped with a terminator wedge socket which

is National Crane’s preferred type of socket (Figure 4-7).

Other wedge socket types are shown on page 4-10.

Reference Only

Loading...

Loading...