National Crane Published 12-21-2011 CTRL #050-09 5-1

1300A OPERATOR’S MANUAL LUBRICATION PROCEDURE AND CHARTS

SECTION 5

LUBRICATION PROCEDURE AND CHARTS

GENERAL

Following the designated lubrication procedure is important

in ensuring maximum crane lifetime and utilization. The

procedures and lubrication charts in this section include

information on the types of lubricants used, the location of

the lubrication points, the frequency of lubrication, and other

information. The information included in this section does not

include lubrication requirements for the truck chassis. Refer

to appropriate truck manufacturer's manual for this

information.

The service intervals specified are for normal operation

where moderate temperature, humidity, and atmospheric

conditions prevail. In areas of extreme conditions, the

service periods and lubrication specifications should be

altered to meet existing conditions. For information on

extreme condition lubrication, contact your local National

Crane Distributor or Manitowoc Crane Care.

Arctic Conditions Below -18°C (0°F)

In general, petroleum based fluids developed especially for

low temperature service may be used with satisfactory

results. However, certain fluids, such as halogenated

hydrocarbons, nitro hydrocarbons, and phosphate ester

hydraulic fluids, might not be compatible with hydraulic

system seals and wear bands. If you are in doubt about the

suitability of a specific fluid, check with your authorized

Manitowoc distributor or Manitowoc Crane Care.

NOTE: All fluids and lubricants may be purchased by

contacting the Manitowoc Crane Care Parts

Department.

Regardless of temperature and oil viscosity, always use

suitable start-up procedures to ensure adequate lubrication

during system warm-up.

Chassis Grease

Lubricating grease of proper consistency is to be applied

periodically at relatively frequent intervals with grease guns

through grease fittings. Minimum apparent viscosity of 300

SUS (Saybolt Universal Seconds) at 100° F (38° C) is

recommended.

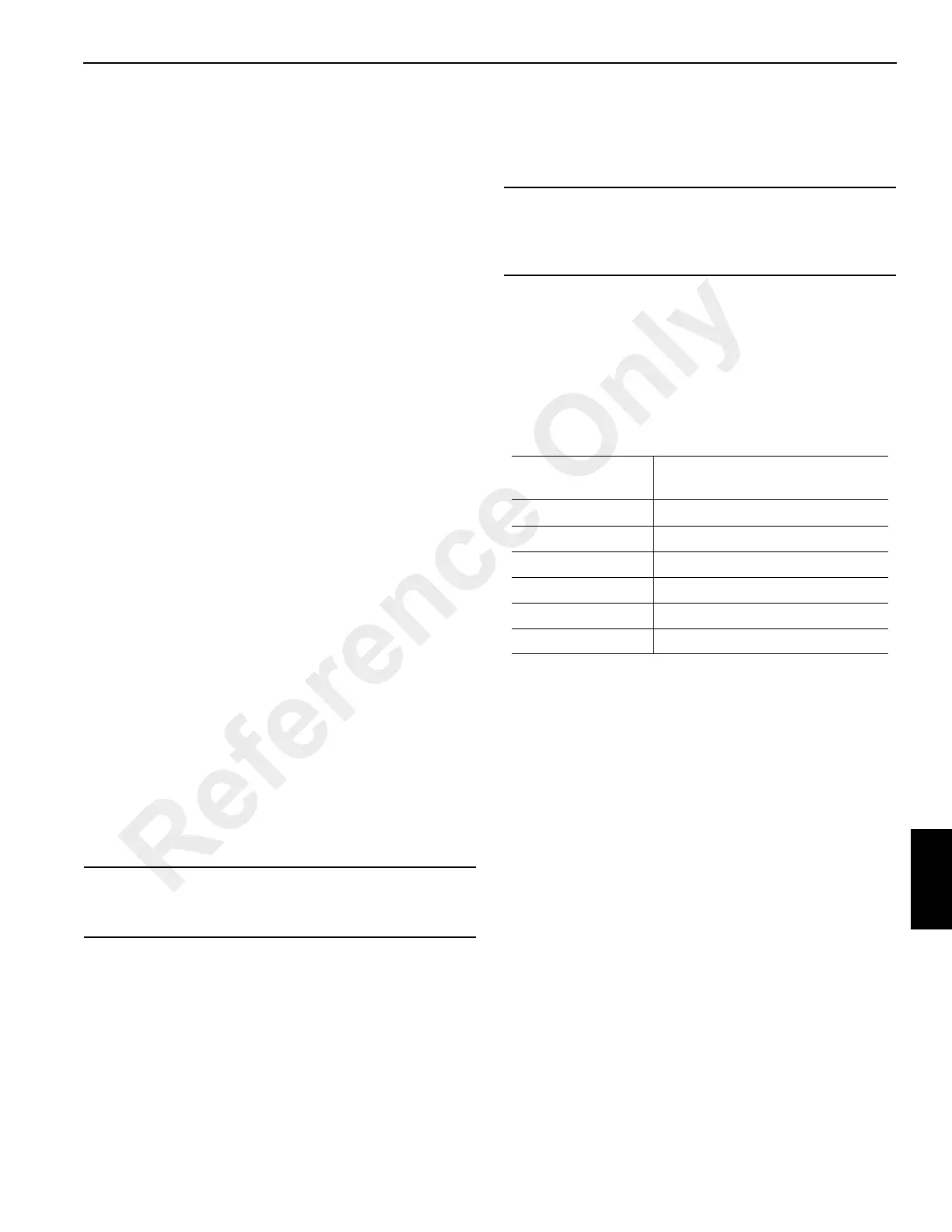

Extreme Pressure Multipurpose Gear

Lubricant

This gear lubricant is compounded to achieve high load

carrying capacity and meet the requirements of either API-

GL-5 or MIL-L-2105C. Unless otherwise specified,

SAE 80W-90 viscosity may be used for year round service.

Low temperature usage is restricted as follows:

Open Gear Lubricant

This is a special high-graphite adhesive lubricant that helps

to eliminate fretting corrosion, is water resistant, and forms a

dry lubrication film which does not attract dust. Lubricant

meets NLGI Class 1-2 specifications.

Anti-wear Additives

Excessive wear in the system may cause a loss in volumetric

efficiency, and may cause shutdowns for maintenance. An

efficient anti-wear oil protects the components against

rusting, resists oxidation and helps prevent wear.

Surface Protection for Cylinder Rods

Steel cylinder rods include a thin layer of chrome plating on

their surfaces to protect them from corroding. However,

chrome plating inherently has cracks in its structure which

can allow moisture to corrode the underlying steel. At typical

ambient temperatures, hydraulic oil is too thick to penetrate

these cracks. Normal machine operating temperatures will

allow hydraulic oil to warm sufficiently to penetrate these

cracks and if machines are operated daily, protect the rods.

Machines that are stored, transported, or used in a corrosive

environment (high moisture, rain, snow, or coastline

CAUTION

Do not use air pressure devices to apply chassis grease

otherwise damage to sealed fittings may result.

CAUTION

The multipurpose grease installed during manufacture is

of a lithium base. Use of a noncompatible grease could

result in damage to equipment.

SAE Viscosity

Number

Minimum Ambient

Temperature F (C)

75W -40 (-40)

80W -15 (-26)

85 +10 (-12)

90 +20 (-7)

140 +40 (+5)

250 +50 (+10)

Reference Only

Loading...

Loading...