4-2 Published 12-21-2011 CTRL #050-09

SET-UP 1300A OPERATOR’S MANUAL

Outrigger Monitoring System (OMS) (Optional—

Standard in North America)

The Outrigger Monitoring System (OMS) aids the operator in

programming the Load Moment Indicator (LMI) by indicating

the position of each outrigger beam. The OMS uses four

sensors, one per outrigger beam, to indicate when an

outrigger beam is positioned to one of three pre-defined

locations, including fully retracted, mid-extend, and fully

extended.

Set up of the outriggers is the same for cranes equipped with

OMS; See “Setting the Outriggers” on page 1.

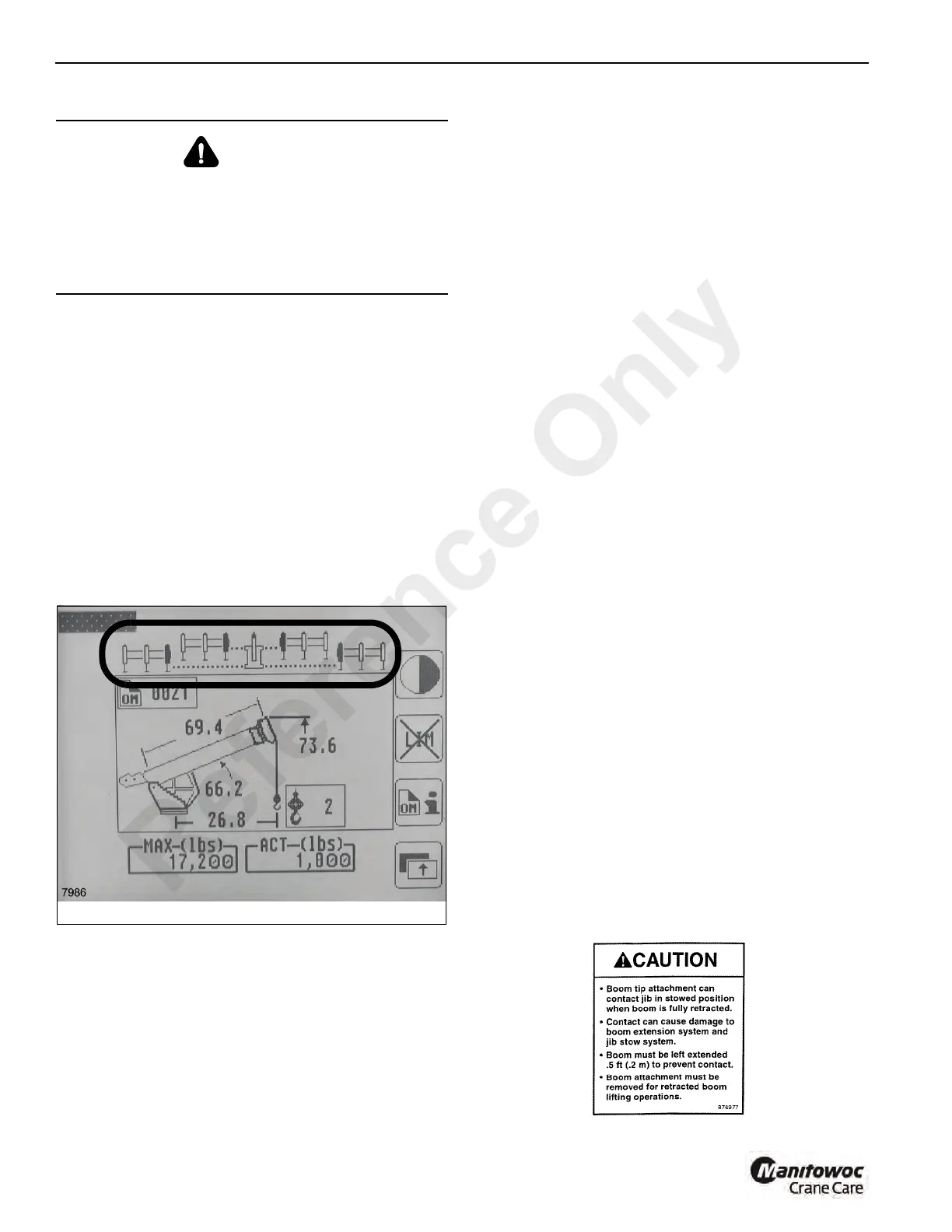

On cranes with OMS the symbols for the outriggers will

display on the LMI screen, refer to Figure 4-2. The

outriggers’ configuration are indicated only, the operator

must program the positions of the outriggers into the LMI.

JIB SAFETY INFORMATION

1. Only use the model 1300A jib on the 1300A boom. Do

not try to use another model’s jib. Other model jibs can

be overloaded and collapse on the 1300A boom.

2. The anti-two-block switch weight and cord must be

attached to the jib when deployed.

3. Do not lift load with the boom tip when the jib is pinned

on the boom tip.

4. Operate with jib by radius when main boom is fully

extended. If necessary, increase boom angle to maintain

loaded radius.

When radius is between points listed on capacity chart,

the load shown at the next longer radius shall be used.

5. Operate with jib by boom angle when main boom is not

fully extended. Do not exceed rated jib capacities at any

reduced boom lengths.

When angle is between points listed on capacity chart,

the load shown at next lower boom angle shall be used.

6. Ensure jib is stowed correctly (Figure 4-3):

a. Removal of swing around pins, C1, without proper

installation of stow pin A and jib swing pin B, may

allow jib to fall off.

b. Extending boom with jib stowed and failure to

remove swing pins, C1, will damage unit upon

extension.

7. Only swing jib into working or stowed position when

boom is horizontal, stow pin A and jib swing pin B, are

removed and swing pins, C1, are in place. Jib could

swing uncontrollably if boom is not horizontal.

8. Crane shall be fully set up according to proper set-up

procedures outlined previously when stowing or

unstowing jib.

9. Operate boom and turn functions very slowly and

carefully when using jib since jibs can increase boom

length by 50%.

10. Area where jib swings around must be clear of

obstructions and power lines when stowing and

unstowing jib.

11. Use safety glasses when pounding pins with hammer.

12. Do not extend/retract boom unless boom is horizontal

when stow pin A and jib swing pin B are removed during

stowing or unstowing procedures.

13. Always put spring clips in pins to ensure that they will

stay in place.

14. When the jib is stowed, the boom can not be fully

retracted if a boom tip attachment option is installed.

WARNING

Tipping Hazard!

The mid-extend outrigger beam lock pin must be engaged

before operating on any beam from the mid-extend

position.

The proper load chart and LMI program must be selected

for the current outrigger configuration.

Reference Only

Loading...

Loading...