Installation

MZ034

English

3

129

WARNING!

A special thread-lock treatment is applied to

the thread on the bolts (see 3A in Picture 3).

Bolts that are installed and later removed

lose this thread-lock treatment, and

therefore can never be used again.

WARNING!

Before installing a Post Mount braking

system, check that the protection film has

been removed from the brake caliper.

WARNING!

Make sure, before every ride, that the brake

cable of the disk brake system is correctly

connected to the proper mounting (see 3B &

3C in Picture 3).

WARNING!

The brake cable must never touch the crown and

stanchions.

3.3 Wheel Installation

Table 5 - Maximum wheel dimension

Fork

Maximum

wheel

dimension

Marathon 2.2” x 26”

MX - All Mountain - Z1 - 66 -

Dirt Jumper - 888 - Junior T

2.8” x 26”

Monster 3.0” x 26”

D-Street 24” 2.5” x 24”

In the event you need to install wheels with

dimensions larger than those specified in Table

5, above, you must verify that:

• The tire turns freely;

• The tire does not make any contact with the

brake arch or V-Brake system;

• The distance between the inflated tire and the

lower part of the lower crown is at least four

(4) mm when the forks’ legs are fully

compressed

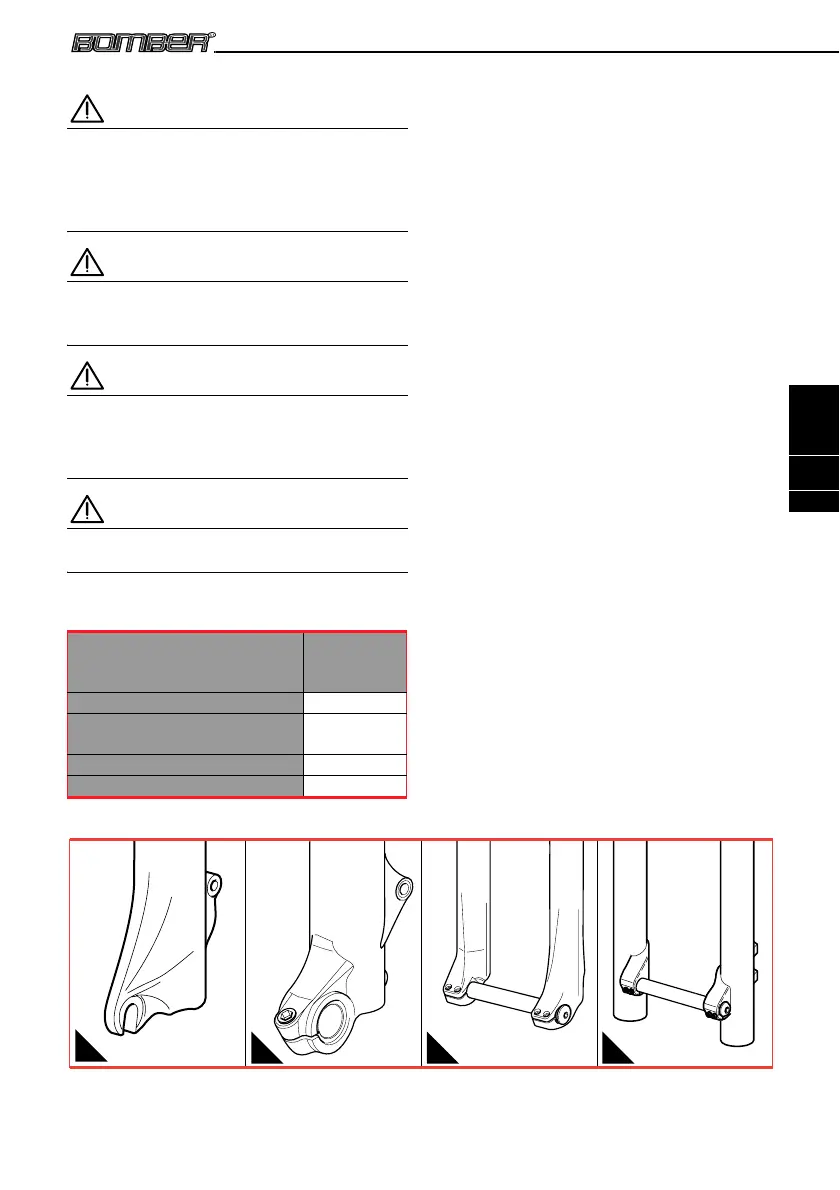

Picture 4 - Wheel securing systems: (4A) standard dropouts, (4B) ø 20mm through-hole axle (forks with ø 32mm

stanchions), (4C) ø 20mm through-hole axle (66 and 888 series forks), (4D) ø 20mm through-hole axle

(Monster).

A

B

C D

3.4 Wheel Axle Securing System

The system for securing the wheel axle to the

fork sliders can be standard, which uses the

traditional advanced dropouts, or have a 20 mm

diameter through-hole axle - see Picture 4

below.

Forks that are created for more intensive use

are provided with a wheel fastening system,

which originates from the motocross application

and uses a 20 mm axle.

3.4.1 Wheel Installation on a Standard

Fork

Install the wheel in compliance with the wheel

manufacturer’s instructions. For correct fork

function after installing the wheel, you will need

to:

• Check the fork-wheel alignment by fully

compressing the fork a few times. The wheel

should not make contact with, or come close

to any portion of the fork.

• Lift the front of the bicycle, and spin the wheel

a few times to verify correct alignment and

spacing with the disk brake or the V-Brake

brake pads. Check the owner’s manual of the

brake system for the proper specifications.

Loading...

Loading...