20 April 2004 / WHISPER 3,5 / USA

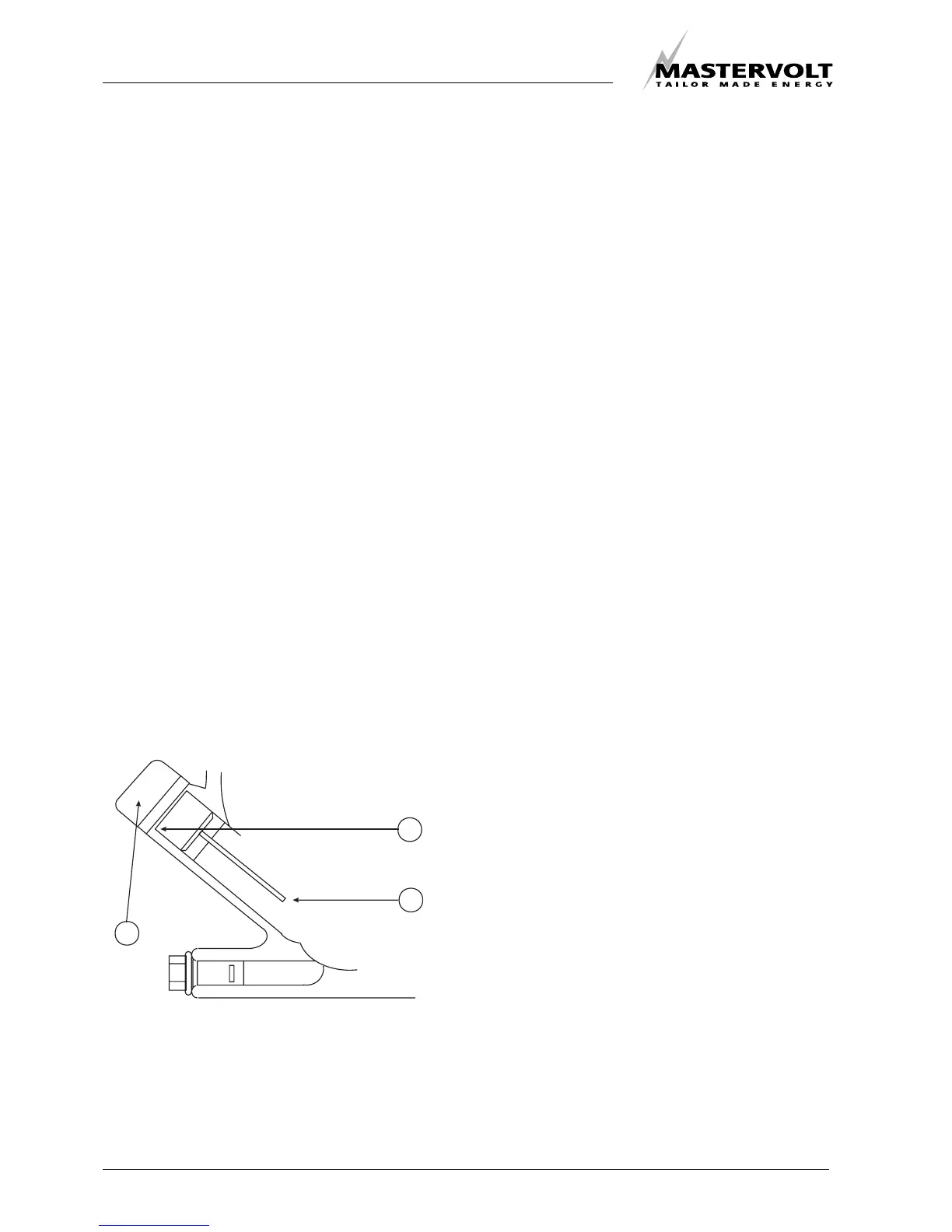

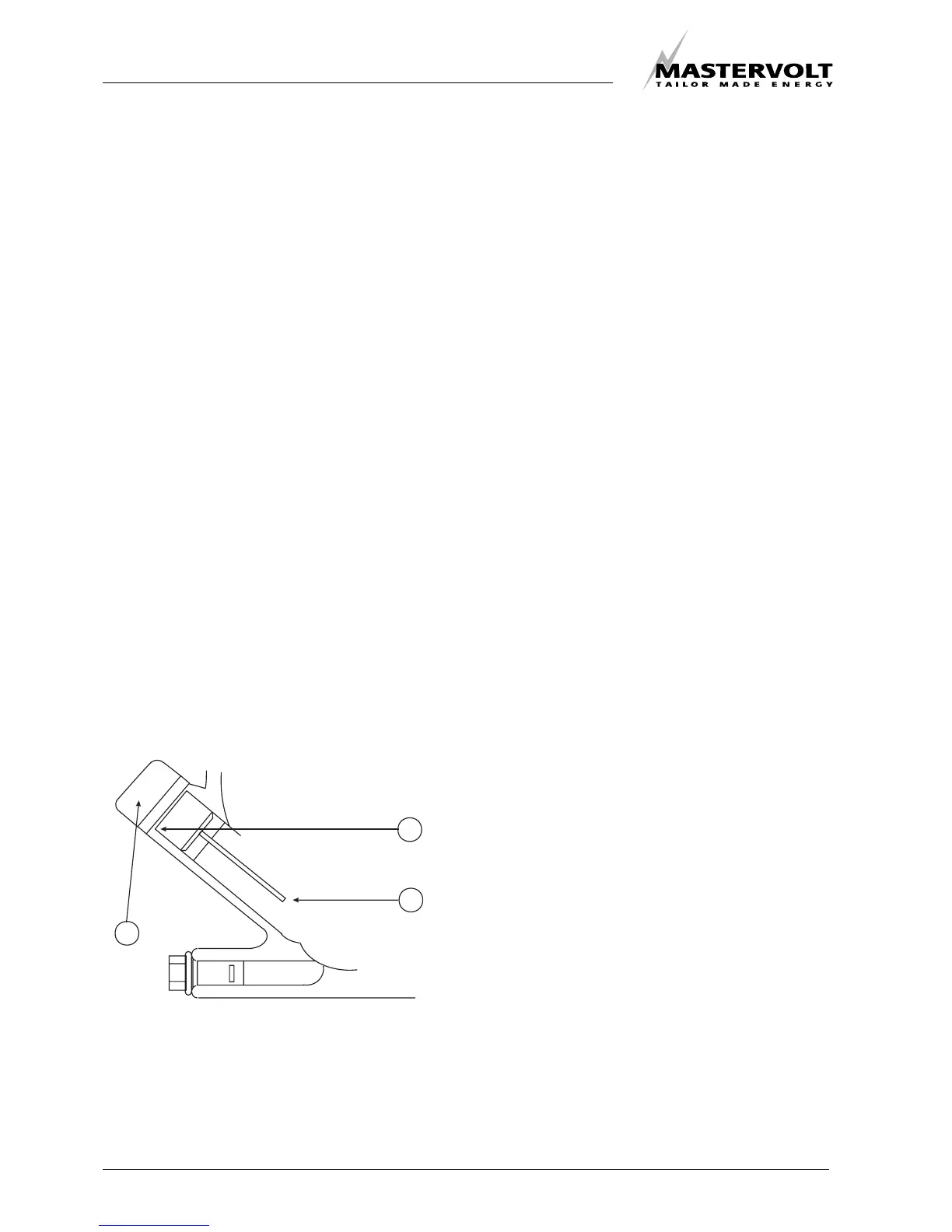

4.2.4 Replacing fuel filter

Filter change depends on contamination of the fuel, but

should be done however, at least every 300 running

hours. Before changing the filter, clamp off the supply

line. Remove the hoses from filter and attach them on the

new filter again. The arrow on the filter housing indicates

the direction of the flow. A clogged filter results in a lack

of output of the generating set.

4.2.5 Cleaning oil strainer

The oil strainer is behind a plug on the bottom of the en-

gine. In the strainer is a magnet to catch the metal parts

which are in the lubricating oil. Once per 1000 hours or

when the oil is contaminated one can clean the strainer

by washing it with petrol or a solvent. A green rubber plug

in the capsule gives access to the strainer. Before taking

out the plug one should sump the oil. Use tissues to

avoid spilling oil in the capsule.

4.3 REGULAR MAINTENANCE

CHECK DAILY:

• Oil level (see fig. 13)

Take care the oil level is never below the mark.

• Hoses for loose connections or deterioration.

•Water inlet filter.

AFTER FIRST 25 HOURS:

• Change oil.

Have the engine run until it is on temperature and

stop it. Drain oil by the sump pump into a suitable

retainer and fill up with fresh oil. Start the engine

again and have it run for 5 minutes. Stop the engi-

ne again and pause for a few minutes to let the oil

gather in the crankcase. Check the level again

and add oil when necessary.

• Check and tighten nuts, bolts, and unions, paying

particular attention to the fuel system.

• Check the valve clearance.

• Observe the exhaust at the normal full load. The

exhaust must be free from soot. Do not allow the

engine to run with a dirty exhaust without investi-

gating the cause as this may result in an expensi-

ve breakdown.

•Check the air vent on a regular basis.

When the air vent is not working properly the en-

gine can fill up with water by siphoning. Water in

the combustion chamber causes serious damage

to the engine.

EVERY 100 HOURS:

• Change oil.

• Check the battery acid level.

• Check battery terminals for corrosion

• Check impeller raw water pump (durability de-

pends on the purity of the sea water. In sandy wa-

ter and warm water wear will increase). When re-

placing the impeller the gasket between the pump

case and the cover should be replaced as well.

So when ordering a spare impeller order a gasket

as well. (50209011 impellor + gasket)

Remove the cover to get access to the impeller.

Remove the old impeller with the help of two

screwdrivers. Install the new impeller and add

some grease. Turn the blades in the direction of

rotation of the pump i.e. anti clockwise looking at

the impeller.

EVERY 300 HOURS:

• Replace the impeller of the raw water pump.

•Check valve clearance.

• replace the fuel filter

Loading...

Loading...