10 April 2004 / WHISPER 3,5 / USA

INFORMATION

2.4.2 Generator control panel

1 Start/stop button

2 Fuse;

3 Fuse.

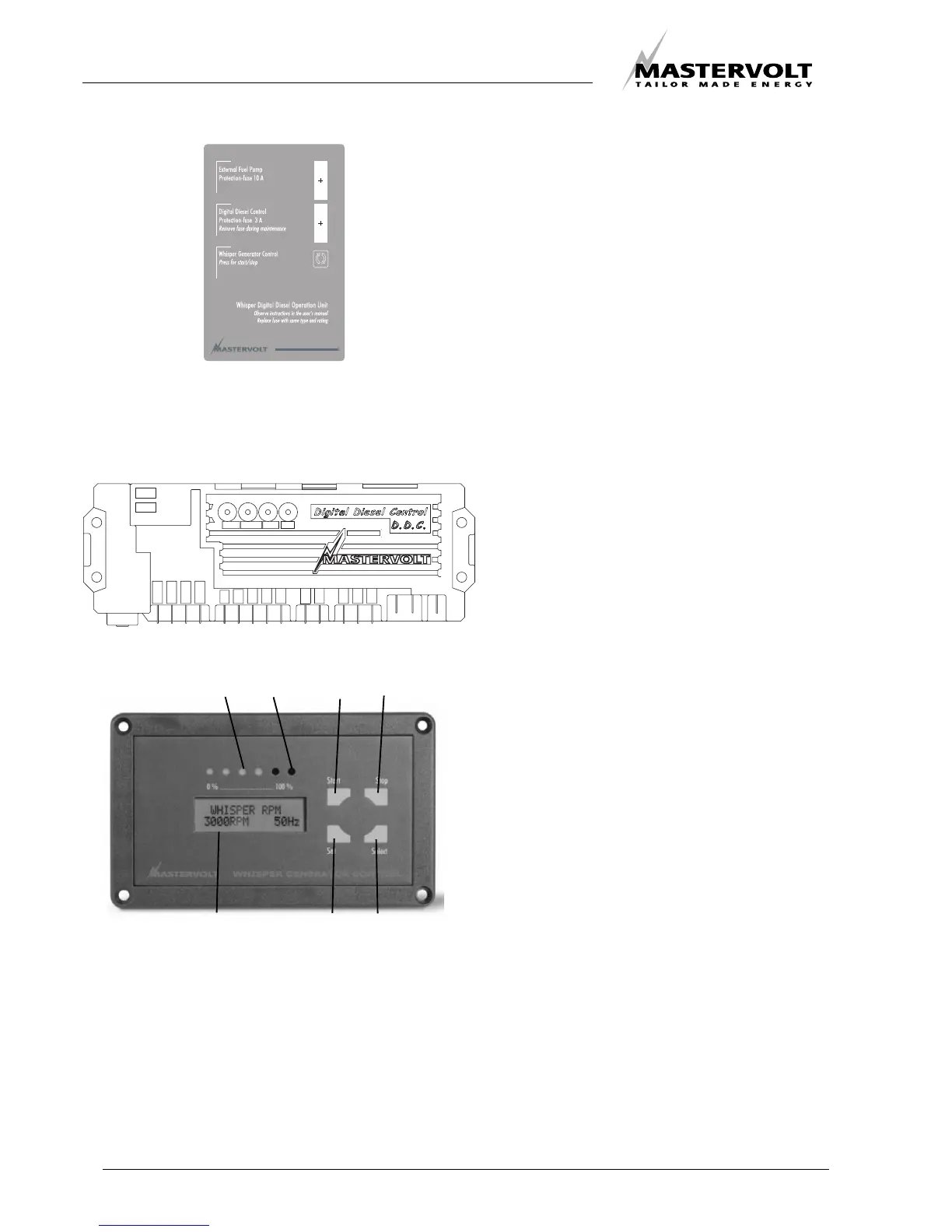

2.4.3 Remote control panel

1 Start button;

2 Stop button;

3 Select button;

4 Set button;

5 Failure lamp;

6 Generator load indicator.

7 Display

2.5 TECHNICAL INFORMATION

2.5.1 AC alternator

The single phase synchronous alternator is directly

coupled, one bearing, brushless, rotating field design,

two pole (3600 RPM) and self regulating.

Residual magnetism causes a small voltage over the sta-

tor windings and allows a current to flow in the windings,

which is magnified because of the feed back effect be-

tween rotor and stator. The field windings in the rotor are

short-circuited over a diode to rectify the current. A capa-

citor over an additional winding in the stator which is at

an angle with the power-winding keeps the voltage stable

within 5 % at the specified rpm and provides voltage fall

off with speed, preventing over-excitation at low engine

speeds and softening the effect of load switching to

relieve the burden on the engine.

Further technical data on the design of the alternator can

be found in drawings and diagrams in this manual.

2.5.2 Engine

The Whisper 3,5 generating set is based on the Kubota

OC60 1 cylinder diesel engine. The engine is indirectly

injected. The engine is oil cooled and the oil is cooled by

a heat exchanger and raw water. The heat exchanger

and all other parts which are in direct contact with the

raw (sea) water are made of seawater resistant material

like naval brass and gunmetal.

The engine has been specially adapted for the Mastervolt

application and is very different from the standard engine

supplied for industrial applications!

2.5.3 Digital Diesel Control system

The standard electrical engine control system is 12 Volt

negative earth, non earth return is available as optional.

Check your identification data to determine which system

is applied. The system is designed according to the

"energise to run" system. The Digital Diesel Control is a

very advanced microprocessor based full automatic

system. Besides automatic start the system offers many

monitoring options. Refer to the separate Digital Diesel

Control users manual.

The microprocessor unit is located on top of the

alternator.

Fig. 5: Digital Diesel remote control panel.

Fig.. 3: Control panel.

Loading...

Loading...