USA / WHISPER 3,5 / April 2004 19

MAINTENANCE

4 MAINTENANCE

4.1 ALTERNATOR

The alternator does not require any maintenance. Perio-

dic inspection and cleaning is recommended, depending

on environmental conditions.

However when the alternator has been idle for a long pe-

riod attention to winding condition is recommended.

The condition of windings can be assessed by measure-

ment of insulation resistance to earth.

The CAPACITOR should be disconnected during this

test. A 500V ‘Megger’ or similar instrument should be

used. The insulation resistance to earth of all windings

should be in excess of 1.0 MOhm. Should the insulation

resistance be less than this value, drying out the genera-

tor windings is essential. Drying out can be carried out by

direct warm air from a fan heater or similar apparatus into

the generator air inlets or outlets.

All bearings are greased for life and not regreasable.

4.2 ENGINE

4.2.1 Preliminary instructions

All regular maintenance can be executed when the en-

closure is open. For repairs we recommend to take out

the generating set to a workshop. The enclosure can be

completely removed by taking out the bolts form the

aluminium bars below the bottom of the capsule.

When oil and dirt have gathered in the enclosure measu-

res have to be taken to avoid spilling oil and polluting the

environment.

The first service on the engine should be carried out after

25 hours of its life. This also applies after a major over-

haul. In the first 25 hours the engine should receive spe-

cial attention:

Long periods of light or no load running in the first 25

hours may lead to cylinder glazing and high oil consump-

tion.

For the same reason it is of the greatest

importance to use the right oil specifica-

tion.

The first time starting up or after running out of fuel it

could be necessary to prime the fuel system.

4.2.2 Bleeding fuel lines

Ensure there is sufficient fuel. The system is self

bleeding. The first time starting up or after running out of

fuel it could be necessary to prime the fuel system. Push

“start” and monitor the display. Extend fuel pumping time

by pushing “stop” when the display indicates “preheat”

and push “start“ again.

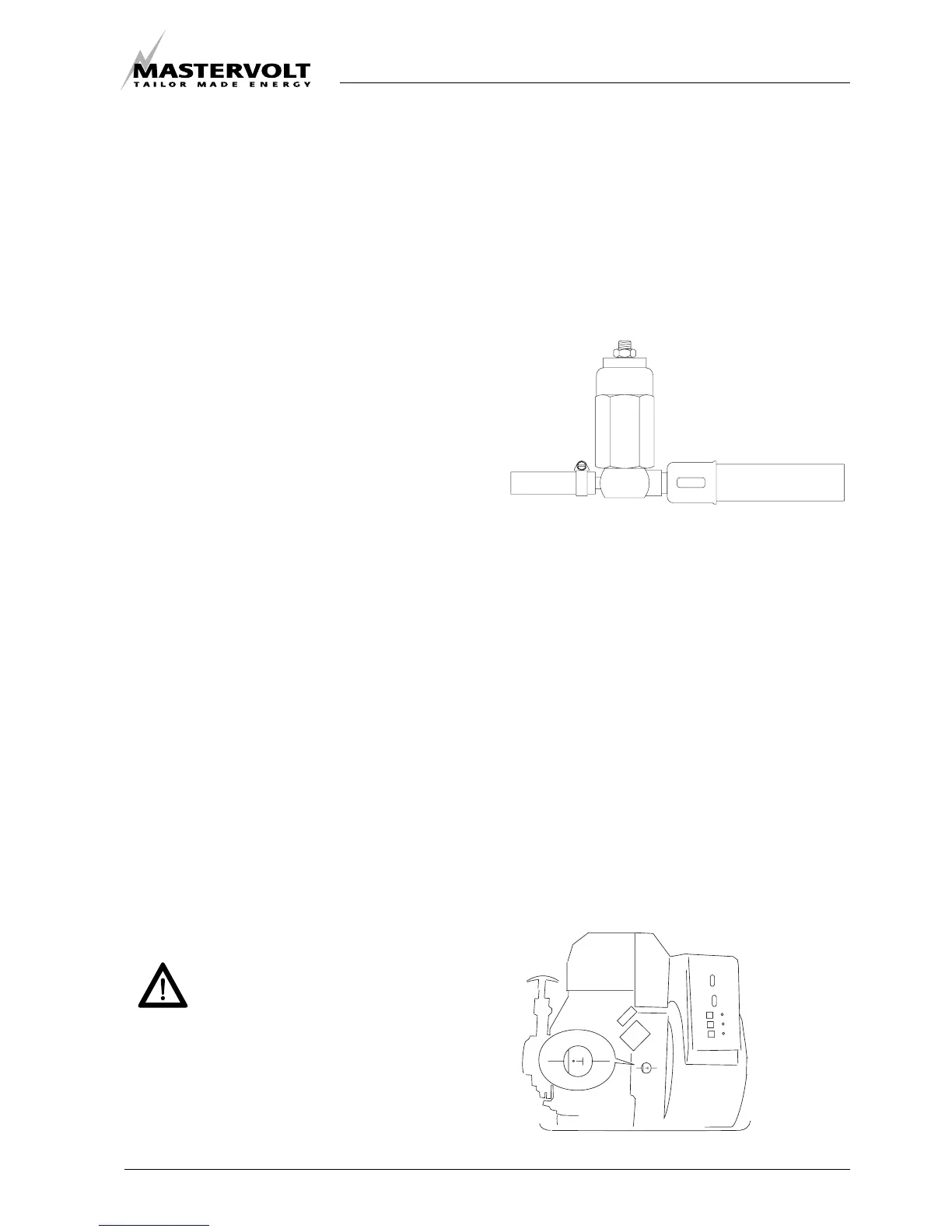

4.2.3 Valve clearance

Tightening torques, refer to § 5.4.2.

When the engine is in cold condition both valves should

have a clearance between 0,0055 and 0,007 inches

(0.14 and 0.18 mm). The adjustment has to be done at

T.D.C. of the compression stroke. Using a pocket light

one can check the position of the flywheel (refer to

picture 12). By using the decompression handle one can

crank the engine easily with a screwdriver to put the

marks in line. Confirm that the valves do not move up or

down when the crankshaft is turned about 20 degrees in

normal and reverse direction of rotation. If the rocker

arms move the piston is on the T.D.C. of the intake or

exhauststroke. In such a case turn the crankshaft 360° in

the direction of engine rotation again. The piston is now

at T.D.C. of the compression stroke. After readjustment

one should crank the engine for 20 rotations and check

the valves again.

Fig. 11: Self bleeding fuel lines.

Fig. 12: Valve clearance.

Loading...

Loading...