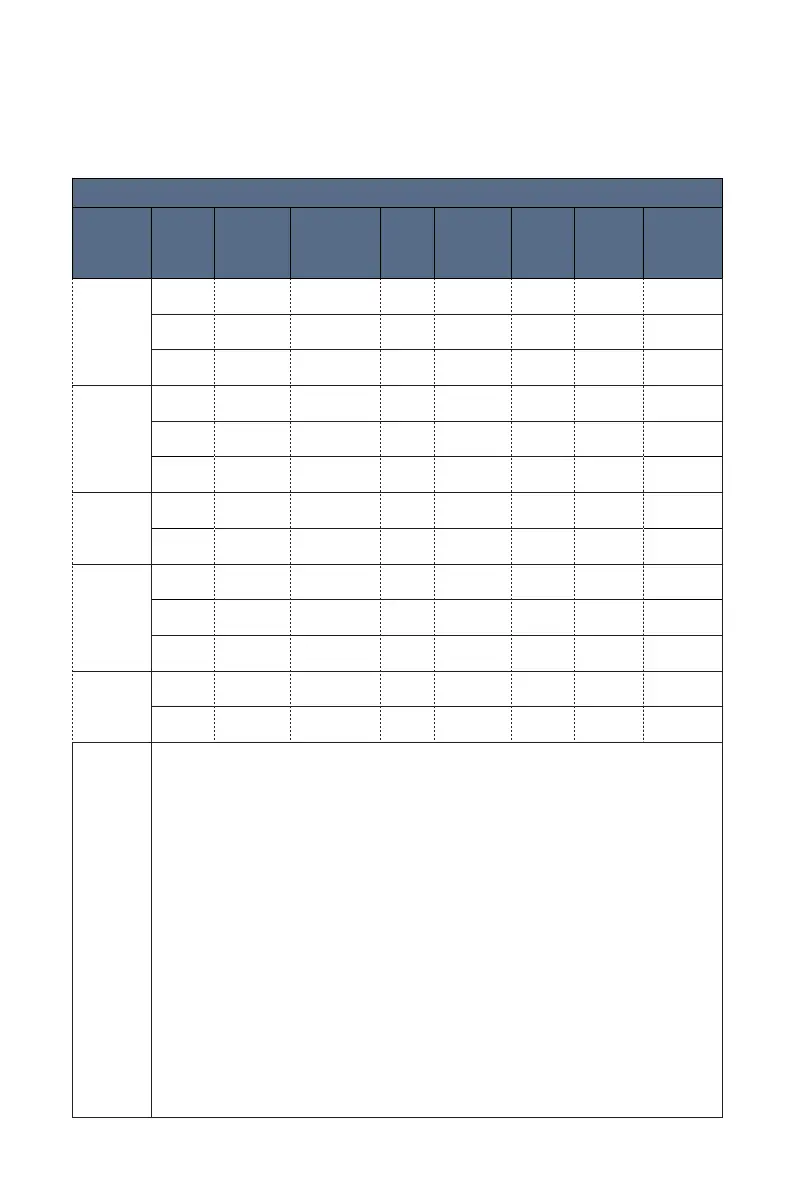

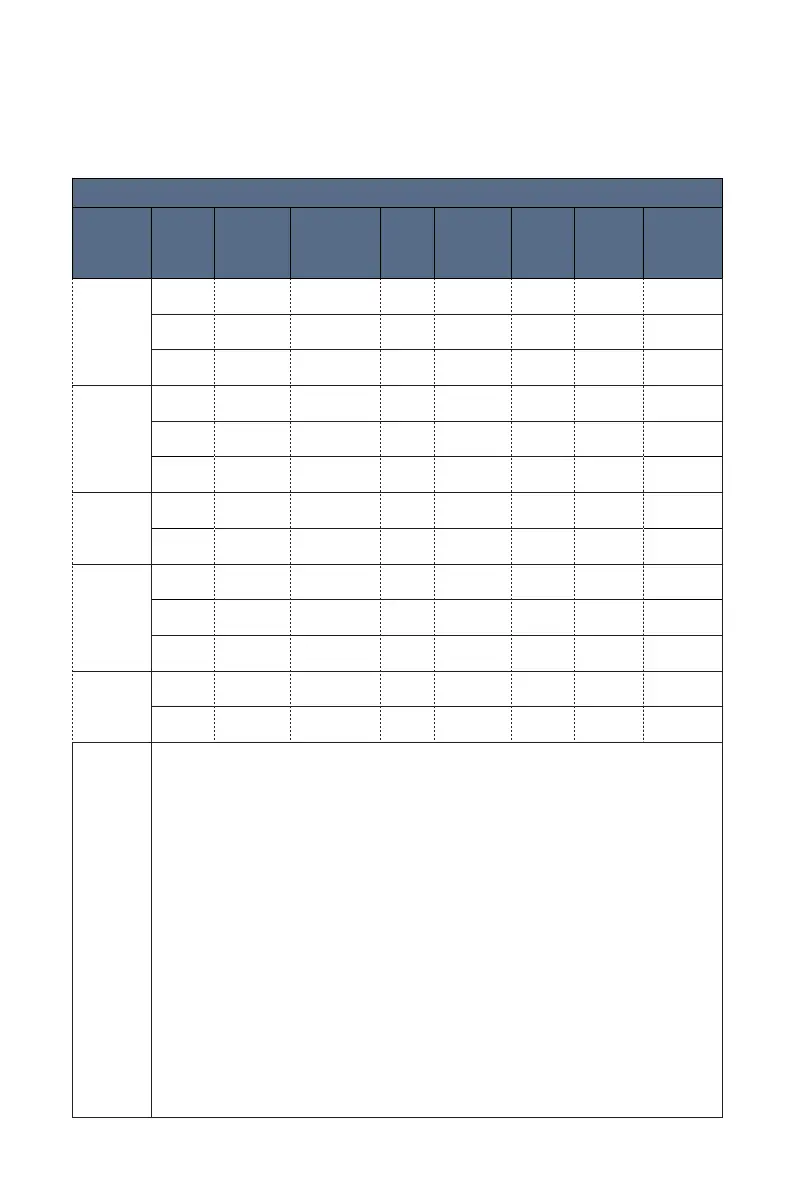

13-Welding Process Parameters

Handheld laser welding process parameter table

Material

type

Welding

form

Thickness

(mm)

Laser power

percentage

(%)

Swing

range

(mm)

Swing

frequency

(hz)

Defocus

amount

(mm)

Air flow

volume

(L/min)

welding

Effect

Carbon Steel

(Q235B)

Stitch

welding

1 45 2-3 60~80 -1~1 15~20 Penetration

Stitch

welding

1.5 100 2-3 60~80 -1~1 15~20 Penetration

Stitch

welding

2.5 100%/D4 1.5-2 50~70 -2~1 15~20 Penetration

Stainless

steel

(SUS304)

Stitch

welding

1 45 2-3 60~80 -1~1 15~20 Penetration

Stitch

welding

2 100 2-3 60~80 -1~1 15~20 Penetration

Stitch

welding

2.5 100%/D4 1.5-2 50~70 -2~1 15~20 Penetration

Brass

Stitch

welding

1 85 2-3 50~70 -1~1 15~20 Penetration

Stitch

welding

2 100%/D4 1.5-2 50~70 -1~1 15~20 Penetration

Galvanized

sheet

Stitch

welding

1 55 2-3 60~80 -1~1 15~20 Penetration

Stitch

welding

2 80 2-3 60~80 -1~1 15~20 Penetration

Stitch

welding

2.5 100%/D4 1.5-2 50~70 -2~1 15~20 Penetration

Aluminum

alloy

(Al6061)

Stitch

welding

1 80 2-3 60~80 -1~1 15~20 Penetration

Stitch

welding

2 100%/D4 1.5-2 60~80 -1~1 15~20 Penetration

Remark

1, the welding form is splicing welding, welding head ratio of 60:120,800 W laser fiber core diameter

of 20 microns;

2, welding protective gas: stainless steel - nitrogen (purity 99.99%), other materials - argon (purity

99.99%);

3. The power percentage is 10-100%, the swing amplitude is 0-4mm (2-3mm is recommended), the

swing frequency is 0-220hz (40-80hz is recommended for manual welding, and the gas flow rate is 15-

20L/min). Under the condition that other parameters remain unchanged, the swing amplitude or welding

speed increases, and the laser power also needs to increase accordingly;

4, welding speed = welding length/welding time (welding speed is influenced by human factors, welding

speed is roughly 10-20mm/s)

Due to different customer welding process (air pressure, manual speed, degree of deflection, welding

Angle), this data is for reference only.

5. D mode enabling condition: D mode can be enabled if the power is ≥90%

6. Due to the difference of welding process (air pressure, manual speed, degree of deflection,

welding Angle) of different customers, this data is for reference only.

7, welding users must wear protective glasses, handheld laser welding machine welding operation

needs to be carried out in an independent space with laser protection; Non-welding personnel and

combustible and flammable materials should be kept away from the welding operation table, and fire

extinguishers should be placed near the welding area.

Loading...

Loading...