48

IMM AGS-2

Remote Evaporator

This section contains data that is unique to AGS-CM/B remote evaporator models

including:

• Refrigerant piping on page 49.

• Dimensions on page 51.

• Vibration isolators on page 58.

• Physical data on page 60.

Data common to both packaged and remote evaporator models are:

• Electrical data on page 32.

• Evaporator pressure drop, on page 25.

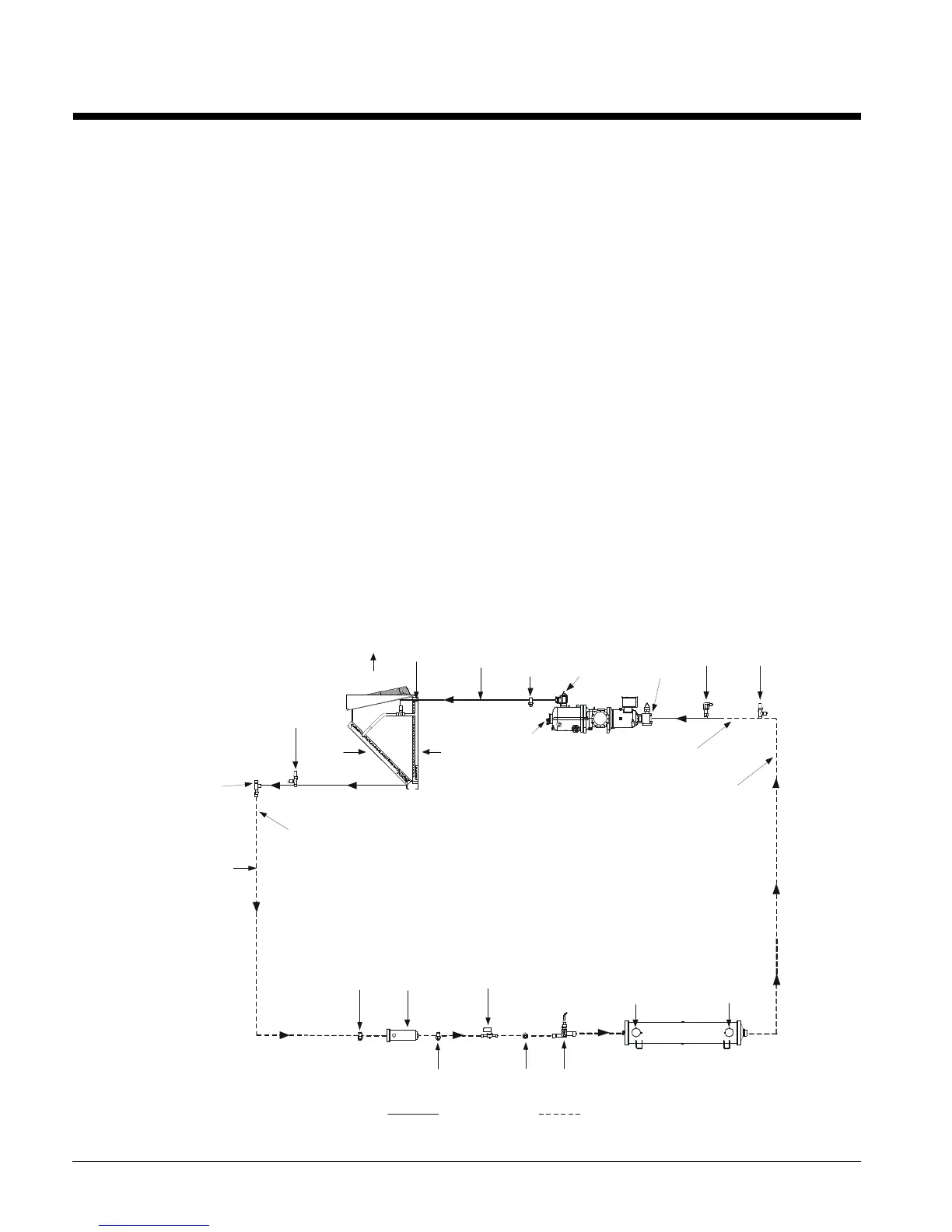

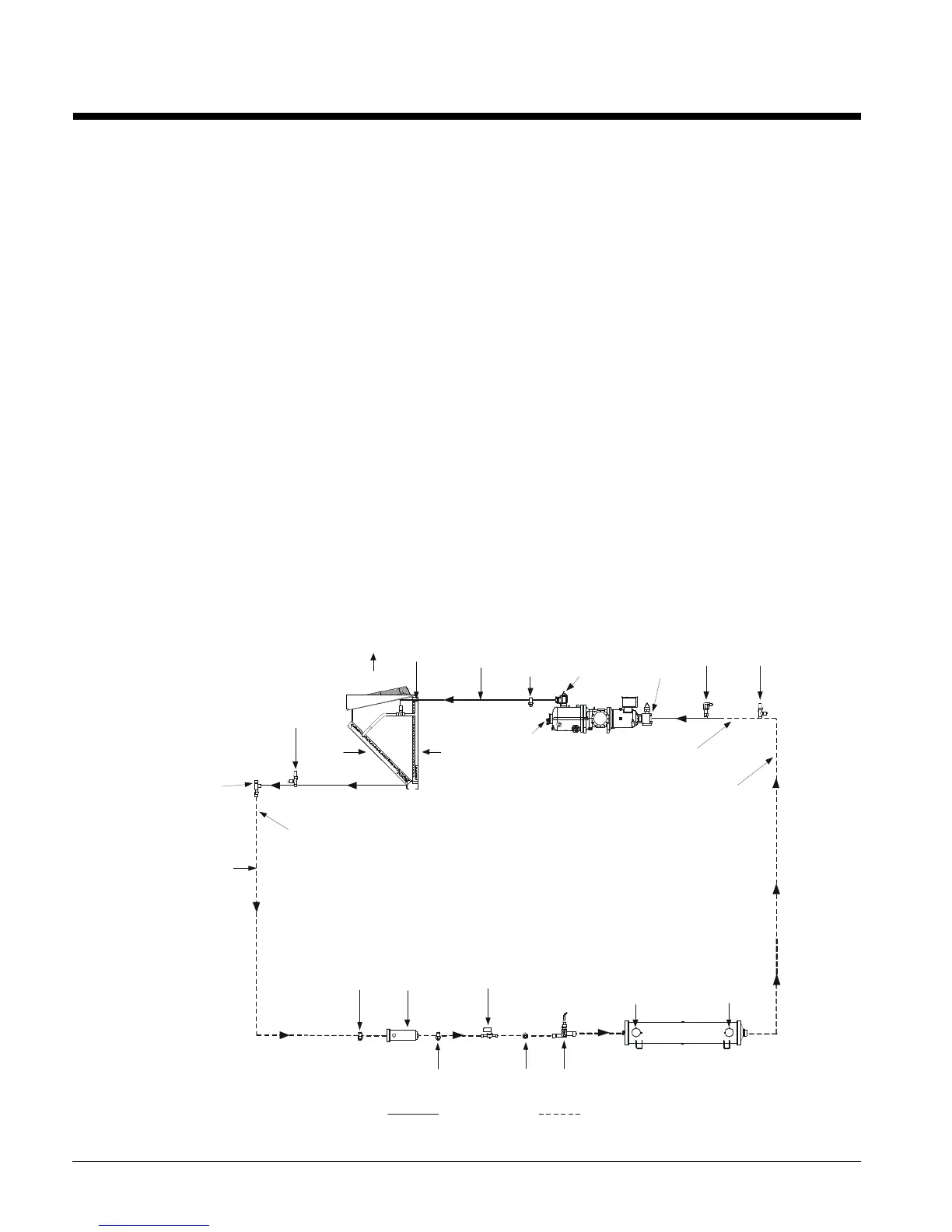

Piping Layout

Figure 26 shows the piping layout for one of the two refrigerant circuits for AGS units with

a remote evaporator. Note that the refrigerant specialties are field installed adjacent to the

evaporator. The outdoor unit, the evaporator, and a kit of refrigerant components are

shipped as separate pieces. The outdoor unit is shipped with an operating charge of

refrigerant. Refrigerant for the evaporator and field refrigerant piping is furnished by the

contractor and must be added in the field.

The location and size of the refrigerant (and water) connections are shown on the

dimension drawings beginning on page 51. Looking at the control panel, circuit #1 is on

the left, #2 on the right.

NOTE: All field piping, wiring, and procedures must be performed in accordance with

ASHRAE, EPA, and industry standards.

Figure 26, Piping Schematic (Remote Evaporator)

CHARGING

VALVE

LIQUID

TUBING

LIQUID

SHUT-OFF

VALVE

SCHRADER

VALVE

FILTER

DRIER

SCHRADER

VALVE

SOLENOID

VALVE

SIGHT

GLASS

EXPANSION

VALVE

WATER OUT

SUCTION LINE

SHUT-OFF

VALVE

TUBING

SCHRADER

VALVE

DISCHARGE

TUBING

AIR

FLOW

AIR

FLOW

AIR

FLOW

CONDENSOR

ASSEMBLY

FRAME 3200

COMPRESSOR

RELIEF

VALVE

VALVE

RELIEF

VALVE

FIELD CONNECTION

LIQUID LINE

SCHRADER

VALVE

(HEADER)

FIELD PIPING

SHUT-OFF

VALVE

Loading...

Loading...