KOMAC00607-09EN 57

disconnect switches to "on." This will energize the crankcase heaters. Wait a

minimum of 12 hours before starting up unit. Turn compressor circuit breakers to

"off" position until ready to start unit.

6. Open the optional compressor suction butterfly as well as the liquid line shutoff

valves, compressor discharge valves.

7. Vent the air from the evaporator water side as well as from the system piping. Open

all water flow valves and start the chilled water pump. Check all piping for leaks

and recheck for air in the system. Verify the correct flow rate by taking the pressure

drop across the evaporator and checking the pressure drop curves in the installation

manual, IMM AGSC-2.

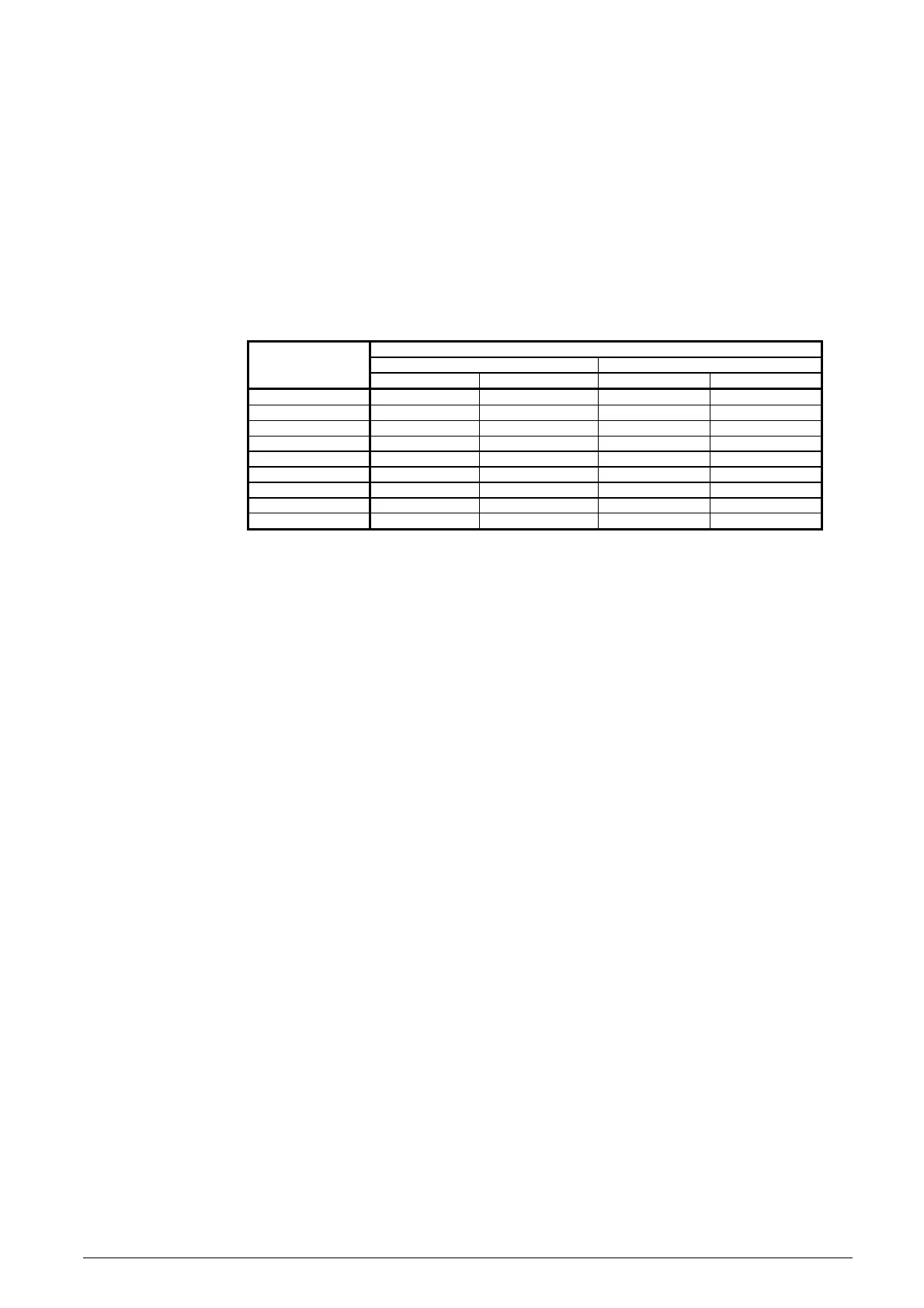

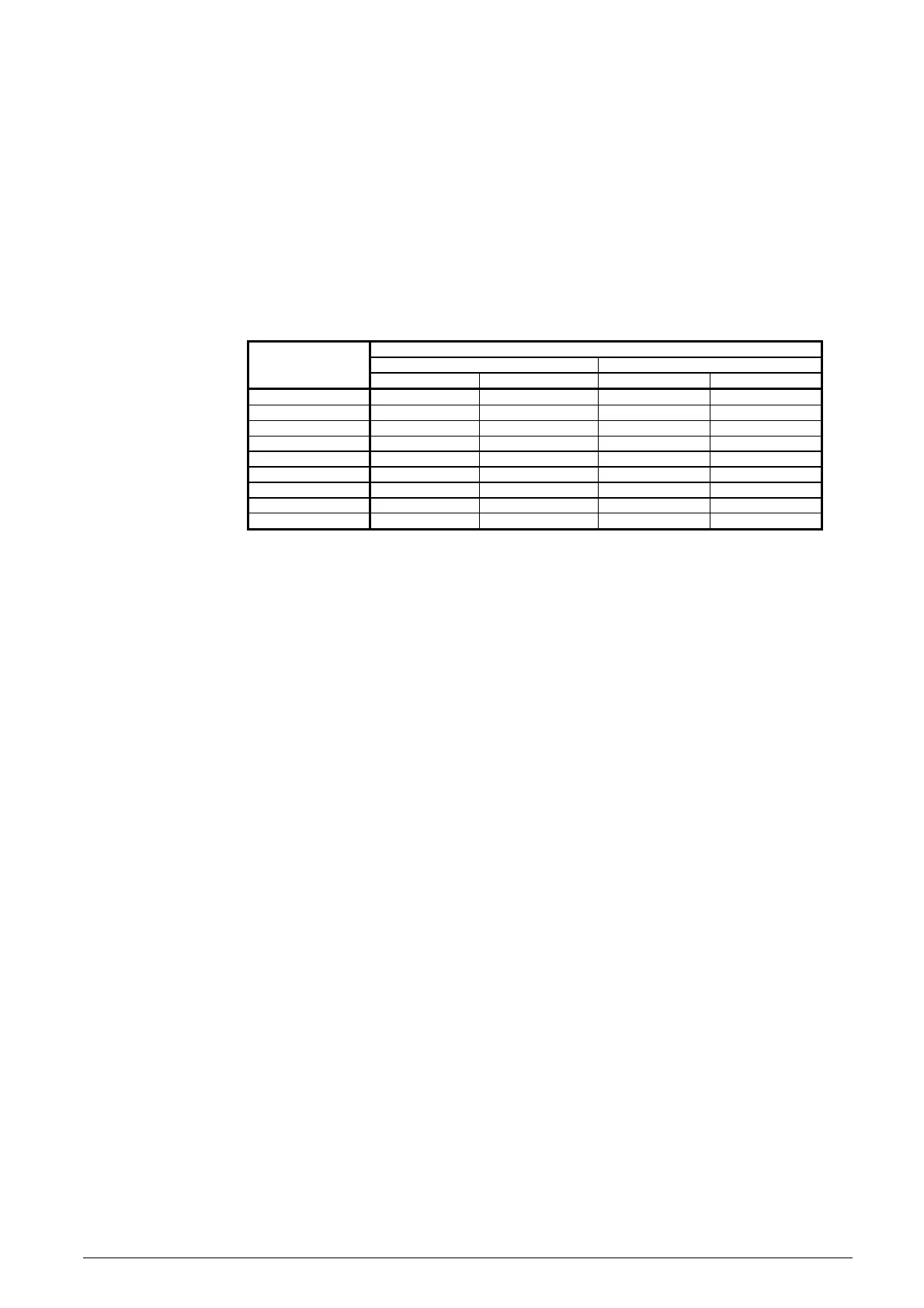

8. The following table gives glycol concentrations required for freeze protection.

Table 2, Freeze Protection

Percent Volume Glycol Concentration Required

For Freeze Protection For Burst Protection

Temperature

°F (°C)

Ethylene Glycol Propylene Glycol Ethylene Glycol Propylene Glycol

20 (6.7) 16 18 11 12

10 (-12.2) 25 29 17 20

0 (-17.8) 33 36 22 24

-10 (-23.3) 39 42 26 28

-20 (-28.9) 44 46 30 30

-30 (-34.4) 48 50 30 33

-40 (-40.0) 52 54 30 35

-50 (-45.6) 56 57 30 35

-60 (-51.1) 60 60 30 35

Notes:

1. These figures are examples only and cannot be appropriate to every situation. Generally, for an

extended margin of protection, select a temperature at least 10°F lower than the expected lowest ambient

temperature. Inhibitor levels should be adjusted for solutions less than 25% glycol.

2. Glycol of less than 25% concentration is not recommended because of the potential for bacterial growth

and loss of heat transfer efficiency.

Loading...

Loading...