IM 742 / Page 5

Electrical Data

1. Verify the compatibility between the voltage and phase

of the available power and that shown on the unit serial

plate. Line and low voltage wiring must comply with

local codes or the National Electrical Code, whichever

applies.

2. Apply correct line voltage to the unit. A

7

⁄8" (22mm) hole

and/or a 1

1

⁄8" (29 mm) knockout is supplied on the side

of the unit. A disconnect switch near the unit is required

by code. Power to the unit must be sized correctly and

have dual element (Class RK5) fuses or an HACR circuit

General

breaker for branch circuit overcurrent protection. See the

nameplate for correct ratings.

3. Three phase 50 cycle units, 380/50/3, require a neutral

wire for 230/50/1 power to the fan circuit.

4. Connect the thermostat/subbase wiring with the power

“off ” to the unit.

5.

Field supplied relays installed on the input terminals W1, W2, Y1,

Y2 or G may introduce electrical noise. Never install relay coils in

series with the inputs.

230 Volt Operation

Fan Assembly

All 208-230 volt single-phase and three-phase units are

factory wired for 208 volt operation. For 230 phase opera

-

tion, the line voltage tap on the 24 volt transformer must be

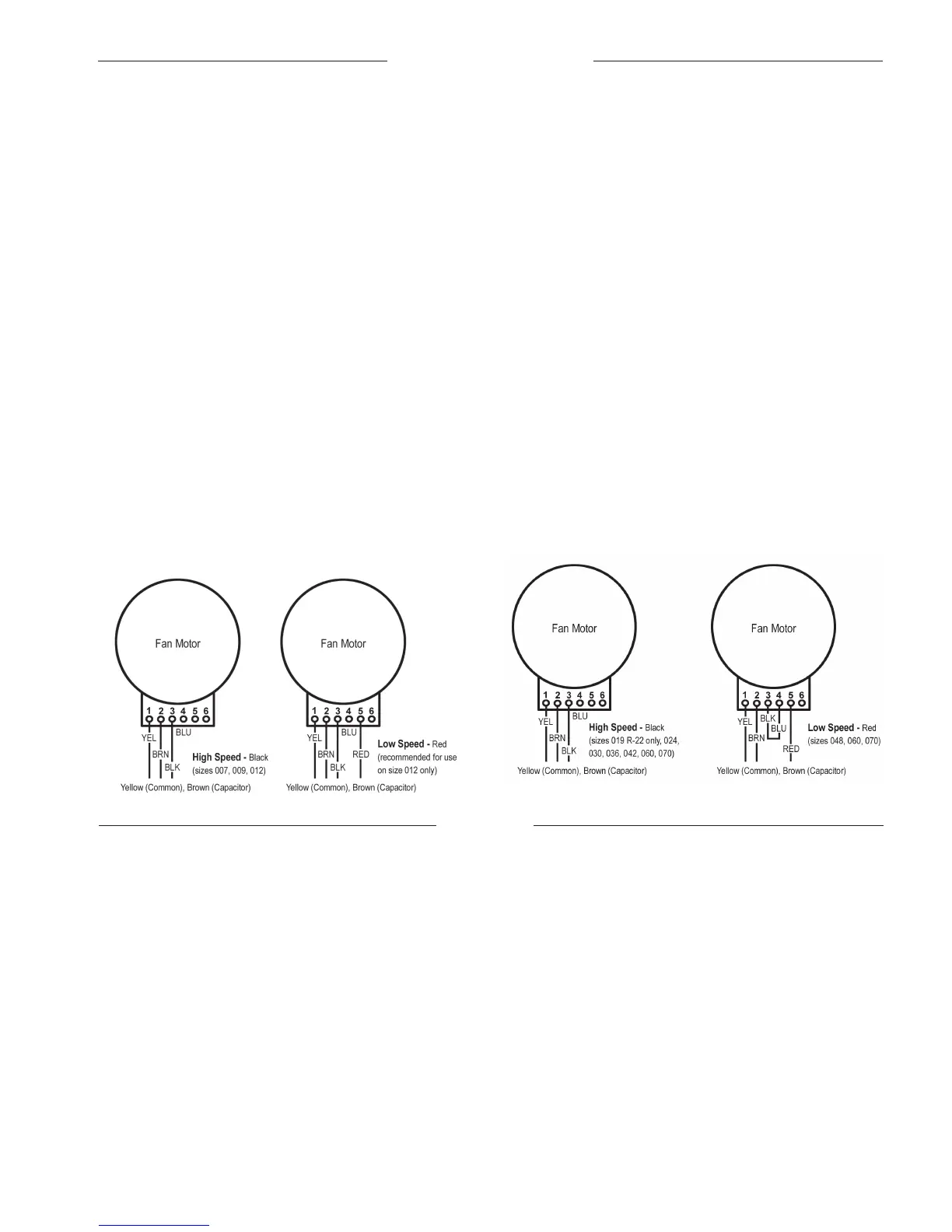

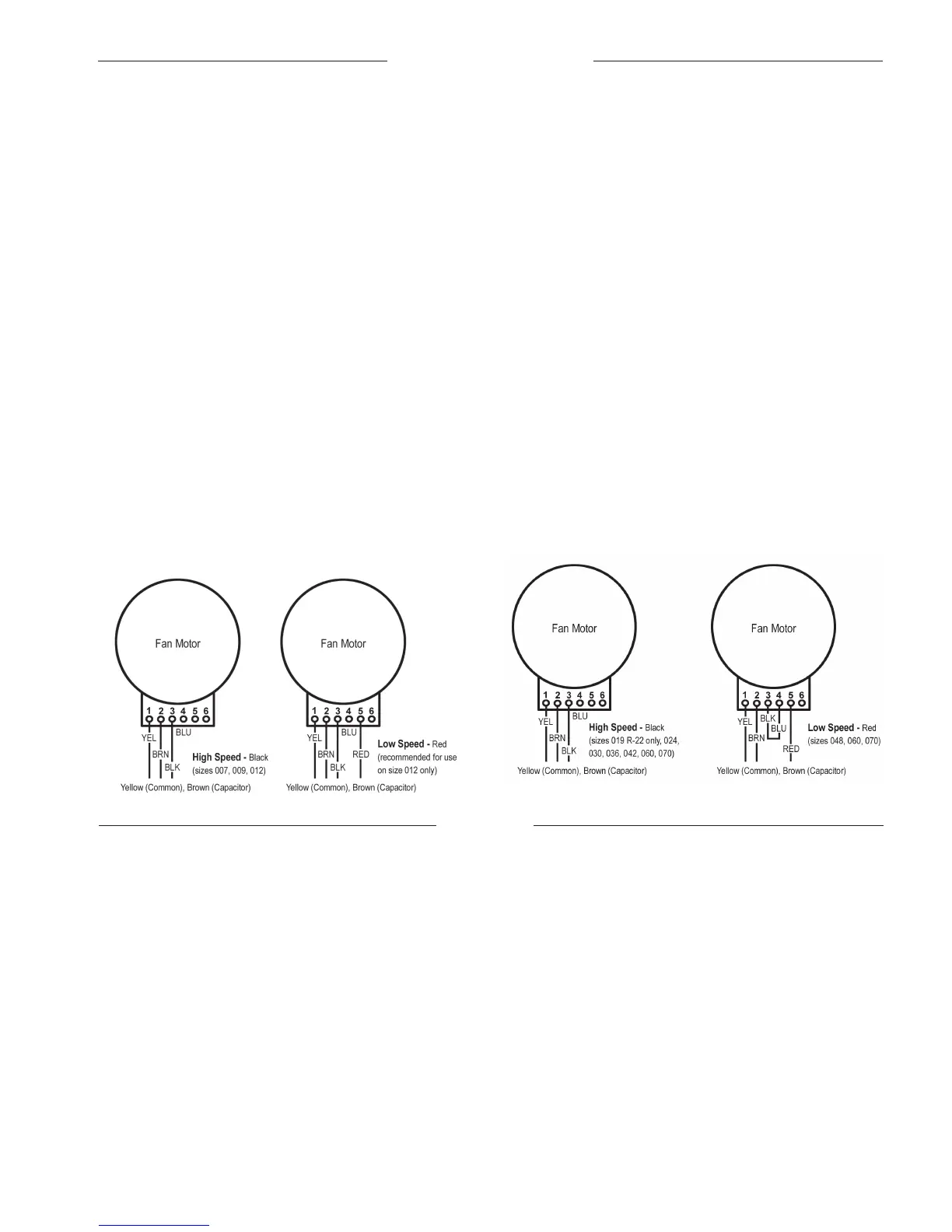

All fan motors are multi-speed, PSC type with integral

mounting brackets and thermal overload protection. The

motor is isolated from the fan housing for minimum vibration

transmission. Fan motors on 019 thru 070 have a terminal

strip on the motor body for simple motor speed change

without going back to the control box. To change fan motor

speed to high on size 015 through 048, interchange the red

wire with the black wire. For low speed, sizes 012, 024,

030, 036, 042, 060 and 070, interchange the black wire with

the red wire. To change the 460 volt motor from high to low

speed, interchange Black and Red wires, then add jumper

between Black and Blue wires. All the fan/motor assemblies

have a removable orifice ring on the housing to accommo-

date motor and fan wheel removal without disconnecting the

ductwork. The fan housing protrudes through the cabinet

allowing adequate material for connection of flexible duct.

Each model unit is shipped from the factory for maximum

performance and minimum sound requirements. Fan sound

levels and performance can be affected by external static

pressure.

changed. Disconnect and cap the red lead wire and inter-

change it with the orange lead wire on the primary of the 24

volt transformer.

Piping

1. All units should be connected to supply and return pip-

ing in a two-pipe reverse return configuration. A reverse

return system is inherently self-balancing and requires

only trim balancing where multiple quantities of units

with different flow and pressure drop characteristics

exist in the same loop. Check for proper water balance

by measuring differential temperature reading across

the water connections. To insure proper water flow, the

differential flow should be 10°F to 14°F (5°C to 8°C) for

units in cooling mode.

A direct return system may also work acceptably, but

proper water flow balancing is more difficult to achieve

and maintain.

2. The piping can be steel, copper or PVC.

3. Supply and return runouts usually join the unit via short

lengths of high pressure flexible hose which are sound

attenuators for both unit operating noise and hydraulic

pumping noise. One end of the hose should have a

swivel fitting to facilitate removal for service. Hard pip

-

ing can also be brought directly to the unit. This option

is not recommended since no vibration or noise attenu-

ation can be accomplished. The hard piping must have

unions to facilitate unit removal. See Figure 5 for typical

piping setup.

4. Some flexible hose threaded fittings are supplied with

sealant compound. If not, apply Teflon tape to assure a

tight seal.

5. Supply and return shutoff valves are required at each

conditioner. The return valve is used for balancing and

should have a “memory stop” so that it can always be

closed off but can only be reopened to the proper posi-

tion for the flow required.

6. No unit should be connected to the supply and return

piping until the water system has been cleaned and

flushed completely. After the cleaning and flushing

has taken place, the initial connection should have

all valves wide open in preparation for water system

flushing.

Figure 4. CCH, CCW, CRH & CRW Sizes 007 thru 070

(Factory wired)

Note: For low speed applications a jumper must be installed between the motor's Black and

Blue terminal.

Figure 4a. CCH, CCW, CRH & CRW Sizes 042 thru 070

(Factory wired, 460 volt motor only)

Loading...

Loading...