Page 6 / IM 742

7. Condensate piping can be steel, copper or PVC. Each

unit includes a condensate connection.

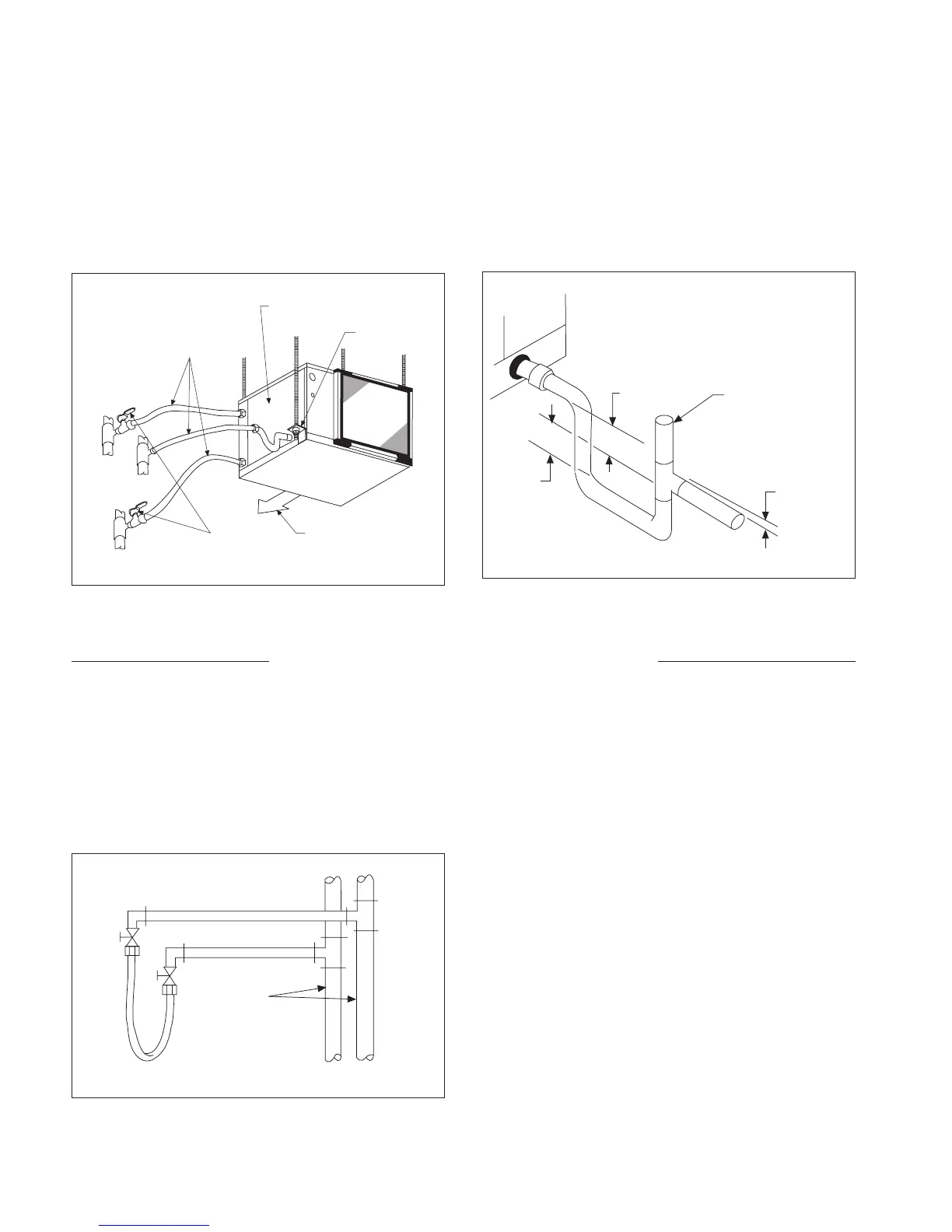

8. The condensate disposal piping must be trapped. The

piping must be pitched away from the unit not less than

1

⁄4" per foot. The unit has a 3/4 inch female pipe fitting

on each water source heat pump to accommodate the

condense drain connection. Factory supplied conden

-

sate hose assemblies have a pipe thread fitting to facili-

tate connection of a flexible vinyl or steel braided hose.

A complete copper or PVC condense system can be

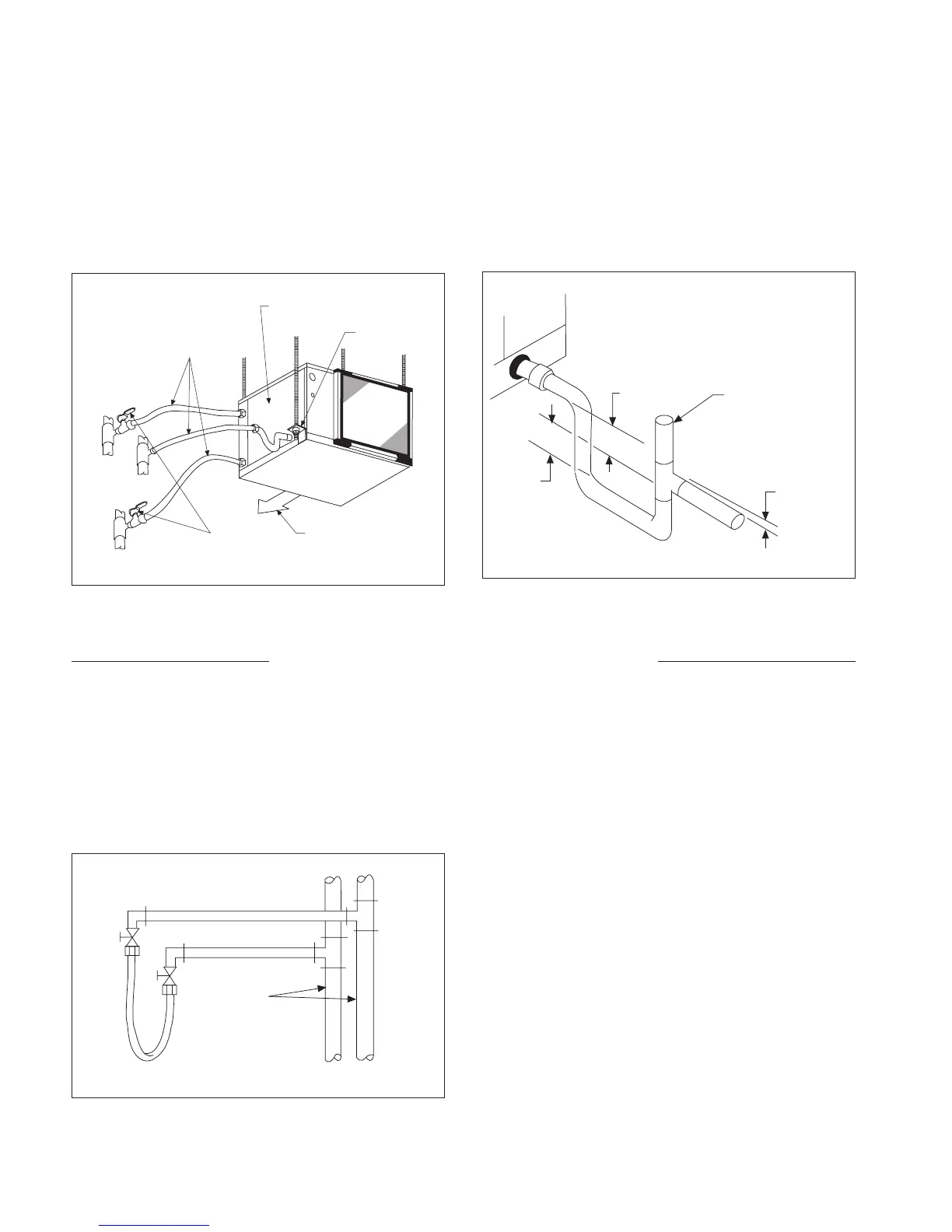

Figure 5. (Sizes 007 through 070 shown)

Figure 6. Condensate disposal trapping detail

Ball

Valves

Supply

Riser

Return

Riser

Condensate

Riser

Supply Air

Optional Field

Installed Vent

1

1

⁄2"

(38 mm)

1

1

⁄2"

(38 mm)

Hanger Kits (4)

Flex Hoses

Electrical Access Panel

1

⁄4" Per Foot

(21 mm Per

Meter)

used. Union fittings in the copper or PVC lines should

be applied to facilitate removal.

9. Do not locate any point in the drain system above the

drain connection of any unit.

10. Automatic flow controlled devices must not be installed

prior to system cleaning and flushing.

11. A high point of the piping system must be vented.

12. Check local code for the need for dielectric fittings.

Cleaning & Flushing System

1. Prior to first operation of any conditioner, the water

circulating system must be cleaned and flushed of all

construction dirt and debris.

If the conditioners are equipped with water shutoff

valves, either electric or pressure operated, the supply

and return runouts must be connected together at each

conditioner location. This will prevent the introduction of

dirt into the unit. See Figure 7.

Figure 7. Supply & return runouts connected together

2. Fill the system at the city water makeup connection with

all air vents open. After filling, close all air vents.

The contractor should start main circulator with the

pressure reducing valve open. Check vents in sequence

to bleed off any trapped air, ensuring circulation through

all components of the system.

Power to the heat rejector unit should be off, and the

supplementary heat control set at 80°F (27°C).

While circulating water, the contractor should check

and repair any leaks in the piping. Drains at the lowest

point(s) in the system should be opened for initial flush

and blowdown, making sure city water fill valves are set

to make up water at the same rate. Check the pressure

gauge at pump suction and manually adjust the makeup

to hold the same positive steady pressure both before

and after opening the drain valves. Flush should continue

for at least two hours, or longer if required, to see clear,

clean drain water.

3. Shut off supplemental heater and circulator pump and

open all drains and vents to completely drain down the

system. Short circuited supply and return runouts should

now be connected to the conditioner supply and return

connections. Do not use sealers at the swivel flare con

-

nections of hoses.

4. Trisodium phosphate was formerly recommended as a

cleaning agent during flushing. However, many states

and localities ban the introduction of phosphates into

their sewage systems. The current recommendation is to

simply flush longer with warm 80°F (27°C) water.

Return Runout

Supply Runout

Mains

Flexible Hose

Runouts Initially

Connected Together

Note: Do not overtorque fittings. The maximum torque without damage to fittings is 30 foot pounds. If a torque wrench is not available, use as a rule of thumb,

finger-tight plus one quarter turn.

Loading...

Loading...