c) Ensure that the compressor is not expose to open air for more than the recommended

time specified by its manufacturer (typically less than 10 minutes). Removed the

seal-plugs only when the compressor is about to be brazed.

d) The system should be thoroughly vacuumed to 1.0 Pa (-700mmHg) or lower. This

vacuuming level is more stringent than R22 system so as to ensure no incompressible

gas and moisture in the system.

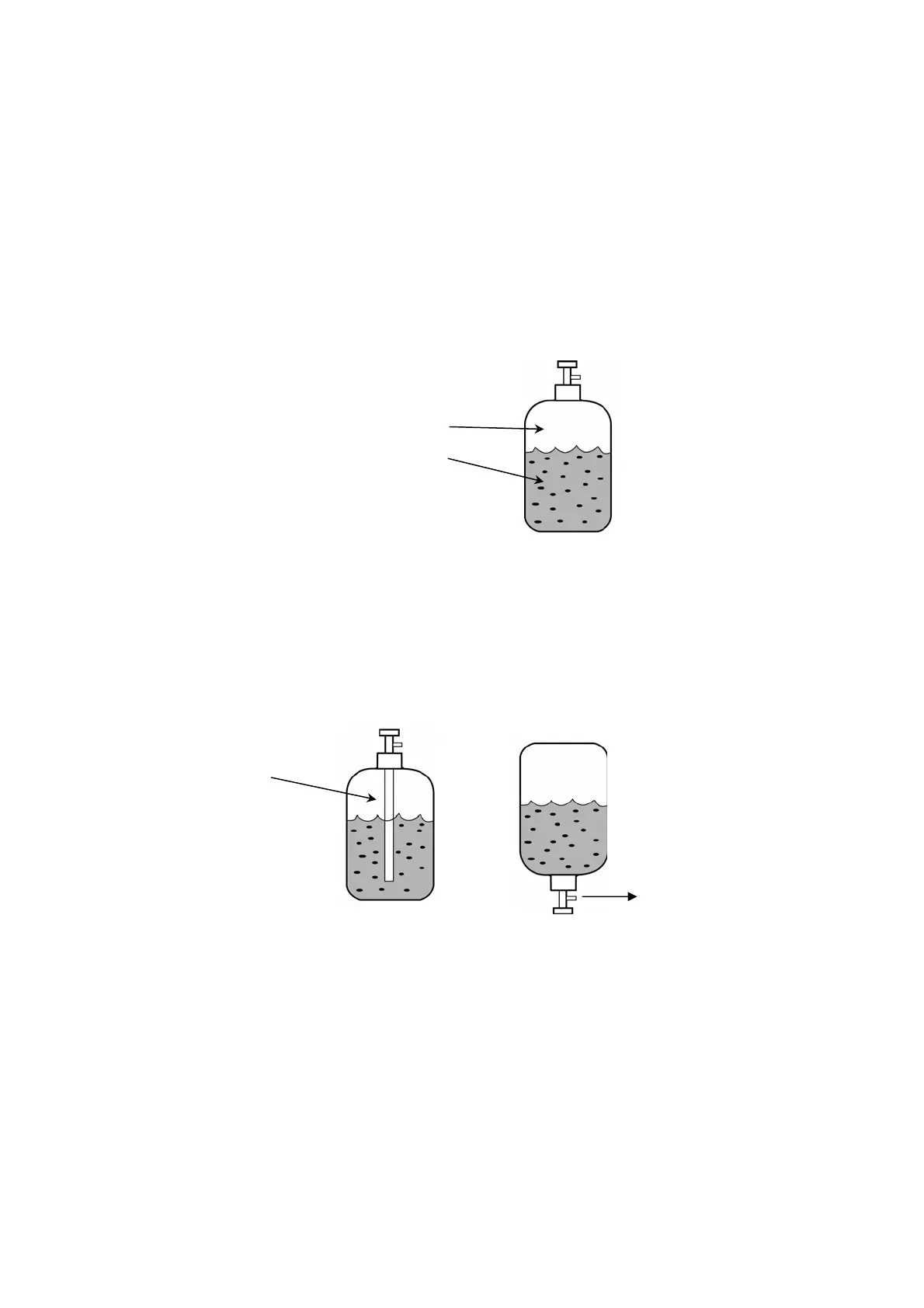

e) When charging R407C, ensure that only liquid is being withdrawn from the cylinder or

can. This is to ensure that only the original composition of R407C is being delivered into

the system. The liquid composition can be different from the vapor composition.

33% / 33% / 34%

23% / 25% / 52%

R32/R125/R134

Composition of R407C in vapour phase

is different from liquid phase.

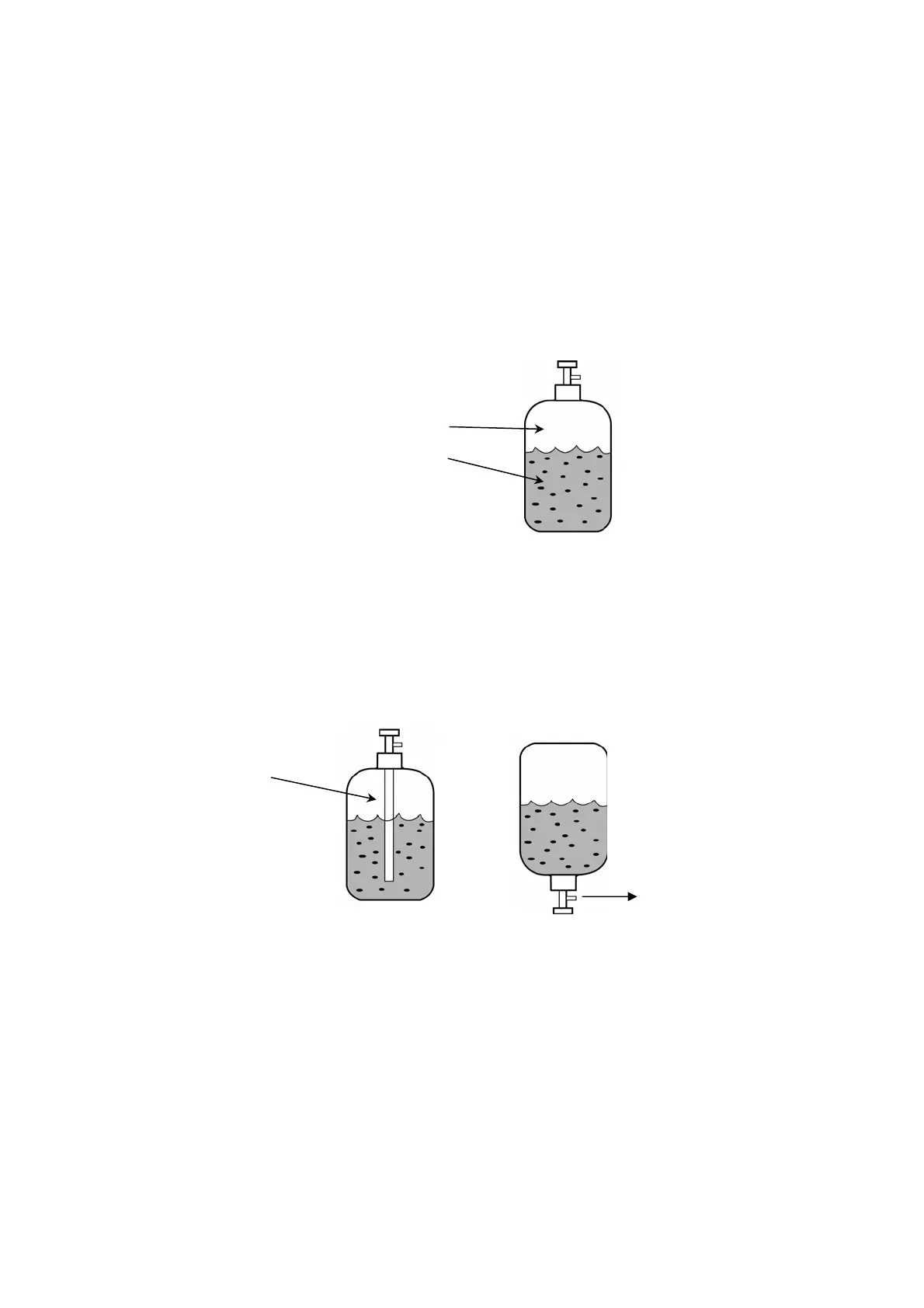

f) Normally, the R407C cylinder or can is being equipped with a dip-pipe for liquid

withdrawal. However, if the dip-pipe is not available, invert the cylinder or can so as to

withdraw liquid from the valve at the bottom.

Liquid

withdrawal

Invert cylinder

without dip-pipe

Dip-pipe

g) When servicing leak, the top-up method, commonly practiced for R22 system, is not

recommended for R407C system. Unlike R22 where the refrigerant is of a single

component, the composition of R407C, which made-up of three different components,

may have changed during the leak. Consequently, a top-up may not ensure that the

R407C in the system is of original composition. This composition shift may adversely

affect the system performance. It is recommended that the system should be evacuated

thoroughly before recharging with R407C.

42

Loading...

Loading...