28 IM710

When a capacity decrease is required, the "Lag" compressor

with the most hours is turned off. When a further capacity

decrease is required, the remaining "Lag" compressor is

turned off. When a further capacity decrease is required, the

"Lead" compressor is staged off.

For detailed information regarding circuit lead/lag operation,

refer to the "Compressor Staging" section of the applicable

operation manual (refer to Table 1 on page 3). Disabled

compressors are not turned on.

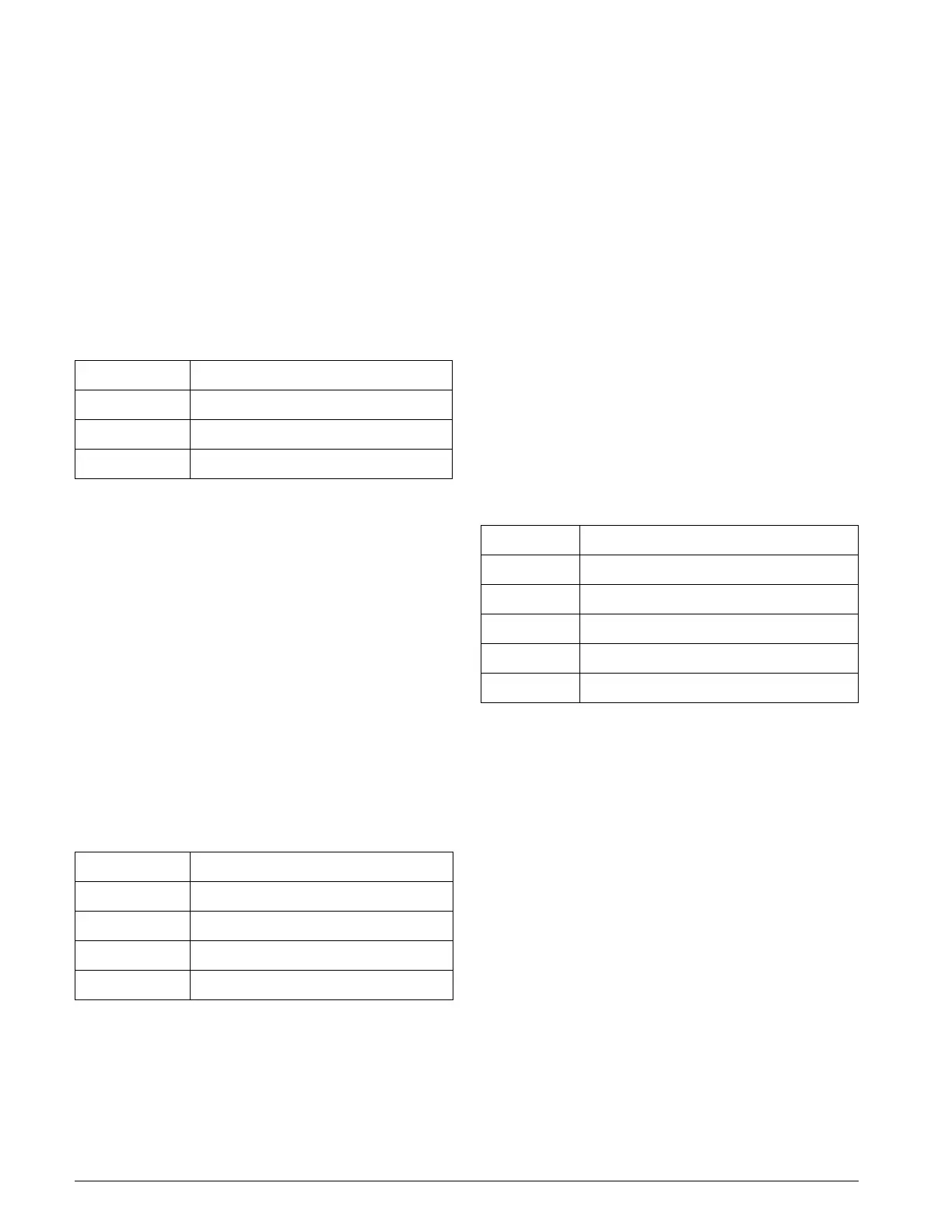

Table 16 summarizes the staging sequencing for the 3-Com-

pressor/3-Stage cooling configuration.

Table 16: 3 Compressors / 3 Stages

4-Compressors/4-Stage

There are four compressors and four independent cooling

circuits. The unit capacity is increased or decreased by turn-

ing compressors on and off. Compressors #1 and #2 provide

the first two stages of cooling. The compressor with the

fewest run hours is staged on first and turned off last. Com-

pressors #3 and #4 provide the last two stages of cooling.

The compressor with the fewest run hours is staged on first

and turned off last. For detailed information regarding cir-

cuit lead/lag operation, refer to the "Compressor Staging"

section of the applicable operation manual (refer to Table 1

on page 3). Disabled compressors are not turned on.

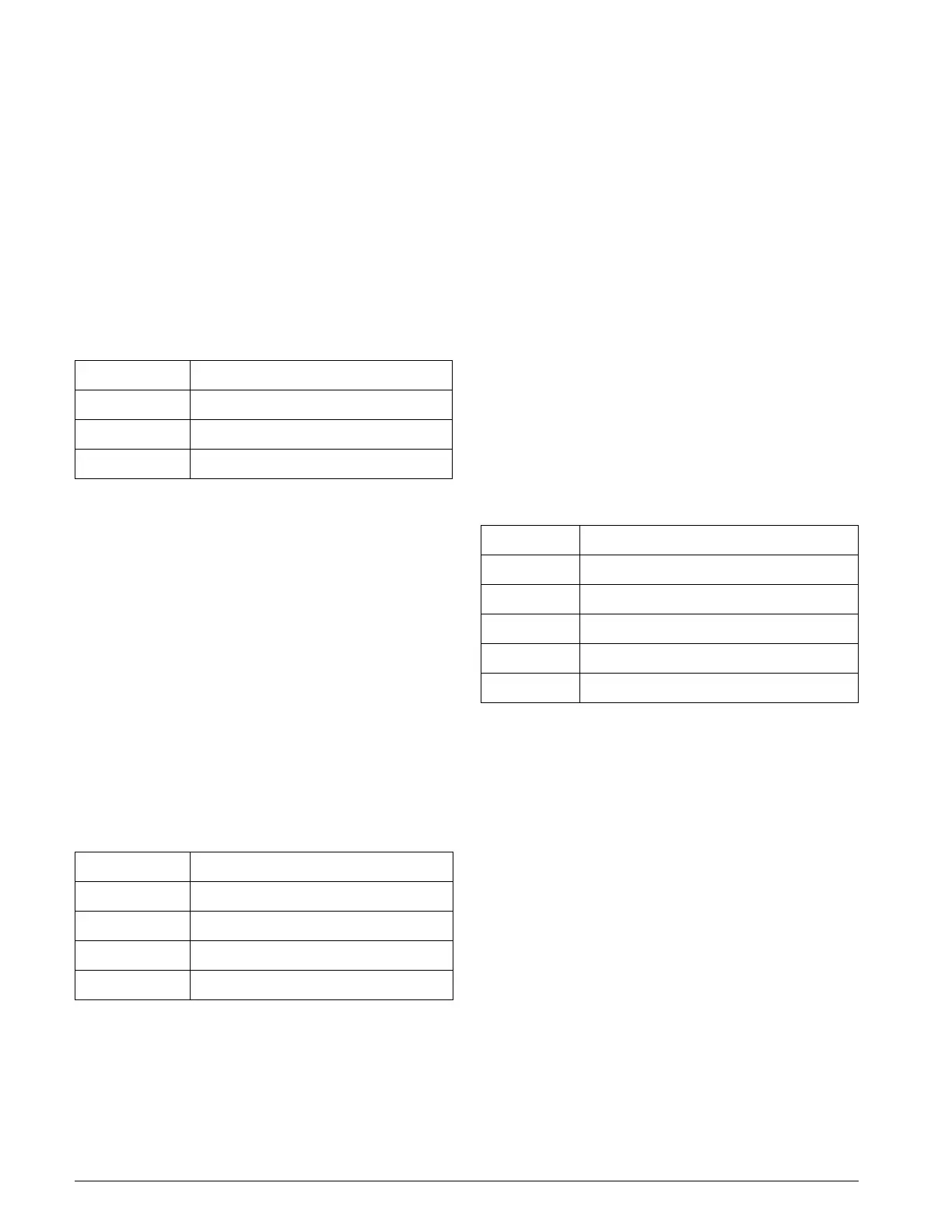

Table 17 summarizes the staging sequencing for the 4-Com-

pressor/4-Stage cooling configuration.

Table 17: 4 Compressors / 4 Stages

3-Small Compressors

& 1-Large compressor/5-Stage

There are three equally sized small compressors and one

large compressor. Each compressor is on an independent

cooling circuit. The unit capacity is increased or decreased

by staging compressors on and off. Compressors #1 or #2

provide the first stage of cooling. The compressor with the

fewest run hours is staged on first and staged off last. Com-

pressors 1 and 2 provide the second stage of cooling. When

further capacity is required, an operating small compressor is

turned off and the large compressor is staged on to provide

the third stage of cooling. When further capacity is required,

Compressors #1 or #2 will provide the fourth stage of cool-

ing. Compressor #3 provides the last stage of cooling.

Note: Stages 3 and 4 are skipped when the large compres-

sor is disabled. The next enabled small compressor

in the sequence is staged on when one or more of

the small compressors is disabled and a stage up is

required.

Table 18 summarizes the staging sequencing for the 3-Small

Compressors & 1-Large compressor/ 5-Stage cooling con-

figuration.

Table 18: 3-Small Compressors & 1-Large compressor/

5-Stage

2-Small Compressors

& 2-Large Compressors/6-Stage

There are two equally sized small compressors and two

equally sized large compressors. Each compressor is on an

independent cooling circuit. The unit capacity is increased

or decreased by staging compressors on and off. The small

compressors #1 or #2 provide the first stage of cooling. The

compressor with the fewest run hours is staged on first and

staged off last. The second stage of cooling turns on the

remaining small compressor (#1 or #2). The third stage of

cooling turns off either #1 or #2 and stages on either #3 or

#4. The third stage has one small and one large compressor

operating. The fourth stage of cooling stages on the remain-

ing small compressor. The fifth stage of cooling turns off one

of the small compressors and stages on the remaining large

compressor. If further cooling is required, the remaining

small compressor is staged on to provide the sixth stage of

cooling. Disabled compressors are ignored. The next

enabled compressor in the sequence is turned on when one or

more compressors are disabled and a stage up is required.

Stages Compressors

11 or 2

2 1,2 or 1,3 or 2,3

3 1,2,3

Stages Compressors

11 or 2

21,2

3 1,2, (3 or 4)

4 1,2,3,4

Stages Compressors

11 or 2

21,2

3 1 or 2,4

4 1,2,4

5 1,2,3,4

Loading...

Loading...