McQuay IM 937 31

Control Panel Components

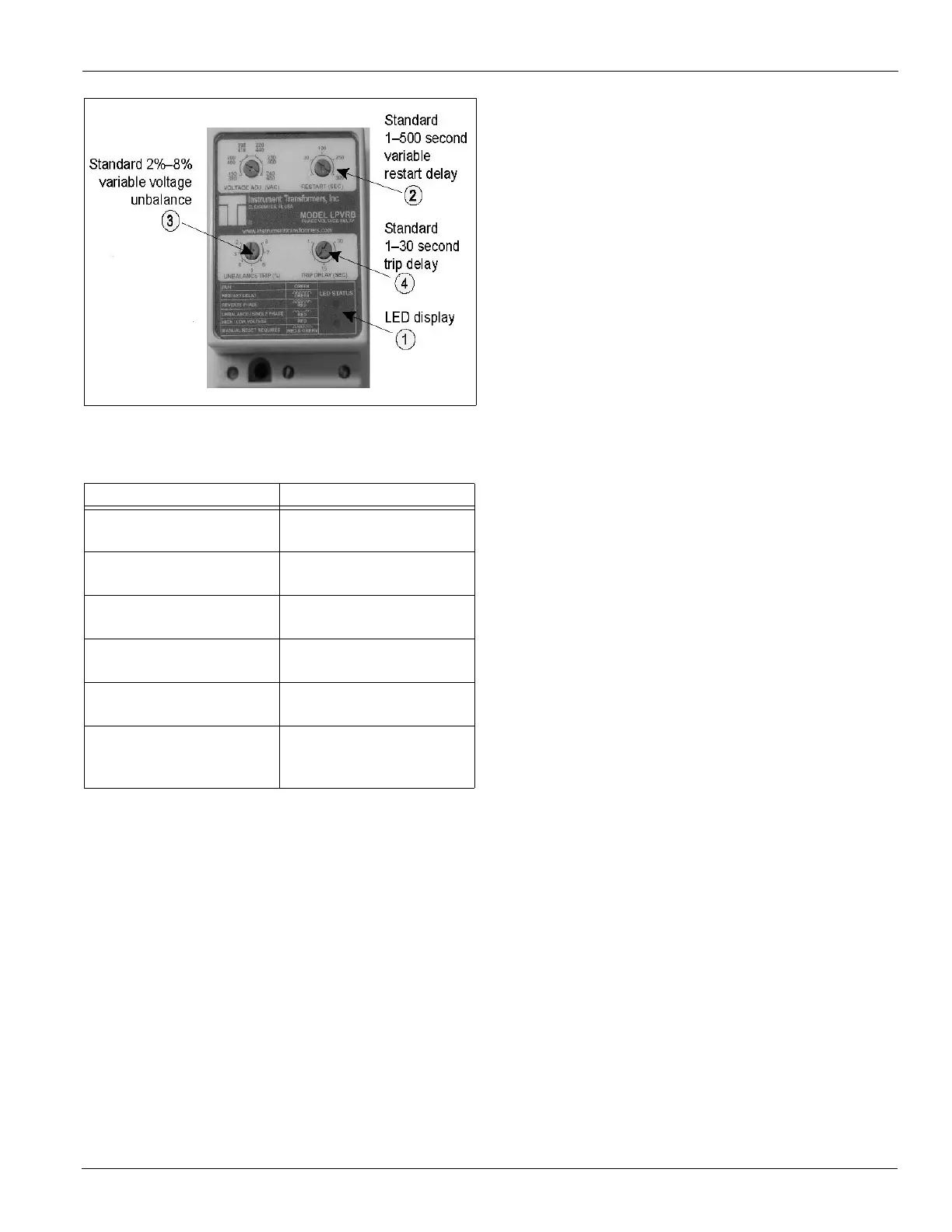

Figure 32: Phase Voltage Monitor

There are two LEDs on the face of the PVM (“1” in Figure 32)

to indicate the following:

Other features:

• Standard 2% to 8% variable voltage unbalance (“3” in

Figure 32).

• Standard 1 to 500 second variable restart delay (“2” in

Figure 32).

• Standard 1 to 30 second trip delay (“4” in Figure 32) (except

loss of phase, which trips at 1 second non-adjustable).

High Pressure Switches

The high pressure switch (HP1-HP6) is a single pole pressure

activated device that opens on a pressure rise. When the switch

opens, it de-energizes the compressor circuit, shutting down

the compressor. The MicroTech III controller displays an

alarm condition. Once the cause of the fault is identified and

corrected, manually reset the unit through the MicroTech III

keypad/display interface. The control is attached to a Shrader

fitting and is located at the compressor. To check the control,

shut off water flow to the condensers and observe the cutout

point on a high pressure gauge. The high pressure control

should open at 360 psig and close at 300 psig. After testing the

high pressure control, check the pressure relief device for

leaks.

Low Pressure Switches

The low pressure switch (LP1-LP6) is a single pole, pressure

activated device that closes on a pressure rise. It senses

evaporator pressure and is factory set to close at 60 psig and

open at 35 psig. Compressor operation is not allowed until the

switch closes. The low pressure switch is an automatic reset

control. If the condition occurs on any one compressor three

times in a 24-hour period, the alarm has to be reset manually

through the MicroTech III keypad/display interface to restart

the compressor. The low pressure switch is attached to a

Shrader fitting and is located at the compressor.

Compressor Motor Protector

All compressors are thermally protected. The solid state

protection device (MP1-MP6) is located in the compressor

junction box. Whenever the protection system opens, the

compressor shut downs for 30 minutes.

The solid state protection device is used on the following:

• Dual circuits—13, 15 hp

• Independent circuits—13, 15, 20 hp

The in-line protection control automatically resets when the

alarm condition is removed and the time delay is satisfied.

The in-line protection device is used on the following:

• Dual circuits—6, 7, 8, 9, 10 hp

• Independent circuits—6, 10 hp

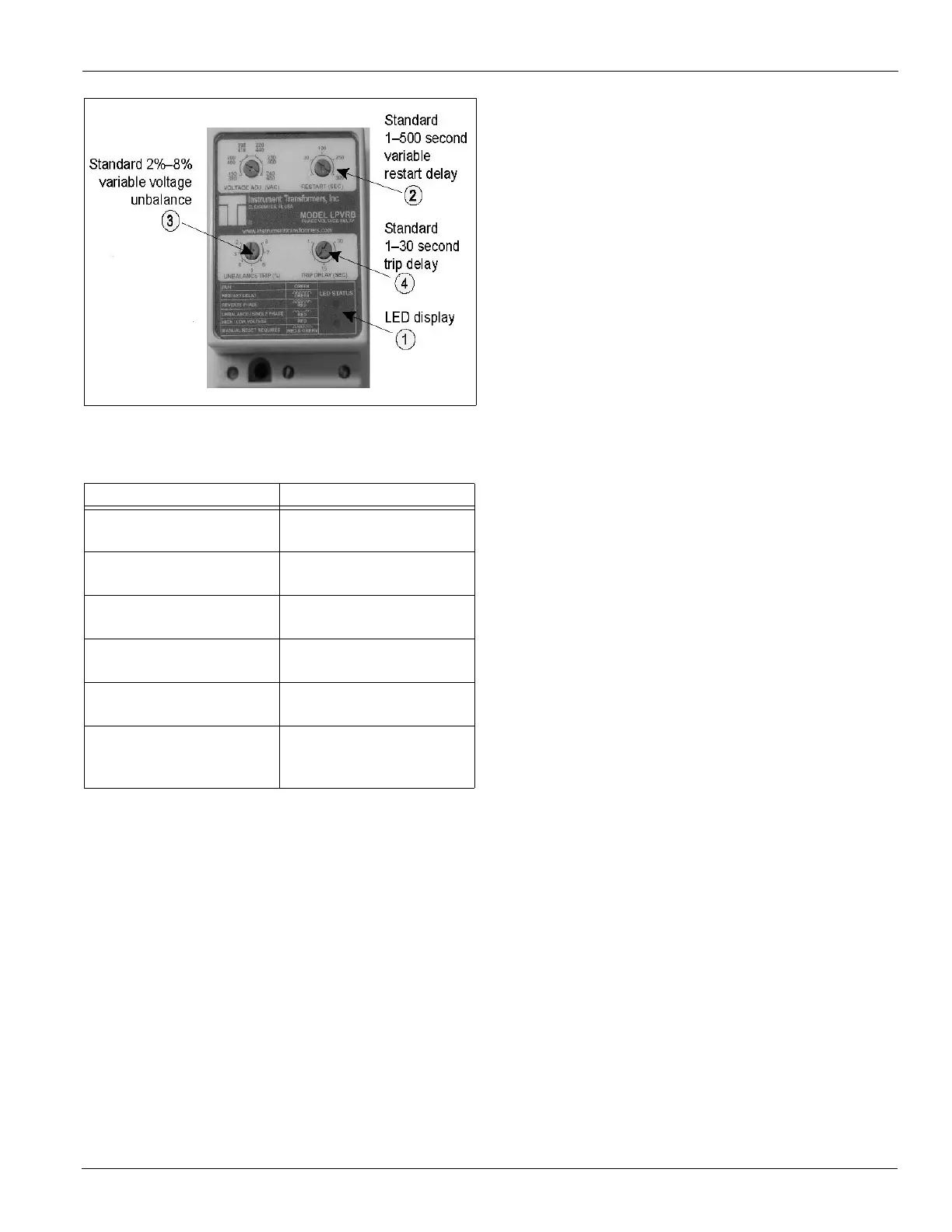

Table 12: LED Indication

Status LED Indicator

Normal operation, no faults,

relay energized

Green LED - steady on

Loss of input phase (relay de-

energized)

Red LED - flash twice, off,

flash twice, off, etc.

Voltage unbalance (relay de-

energized)

Red LED - flash twice, off,

flash twice, off, etc.

High or low voltage (relay

de-energized)

Red LED - steady on

Phase reversal (relay de-

energized)

Red LED - pulse on, off, on,

off, etc.

Restart delay (fault cleared,

PVM pending restart, relay

de-energized)

Green LED - pulse on, off,

on, off, etc.

Loading...

Loading...