40 McQuay IM 937

System Check, Test, and Start

System Check, Test, and Start

General

Start-up and service of this equipment must be performed only

by trained, experienced personnel. A representative of the

owner or the operator should be present during start-up to

receive instruction in unit operation, care, and adjustment.

Complete a check, test, and start-up procedure. The completed

check test and start form (supplied with each unit) must be

signed and returned to McQuay International.

Note: Before opening service panels, always lock out and tag

out the power disconnect switch.

Pre Start-Up

1 Check that the unit is completely and properly installed

with ductwork connected.

2 Check that all construction debris is removed and filters are

clean.

3 With all electrical disconnects open, check all electrical

connections to be sure they are tight. Although all factory

connections are tight before shipment, shipping vibration

can cause loosening.

4 Check all compressor valve connections for tightness to

avoid refrigerant loss at start-up. Although all factory

connections are tight before shipment, shipping vibration

can cause loosening. See Table 13 for proper valve torque

values.

5 Check the tightness of setscrews in bearings, drives, and

fan wheels. If retightening is needed, make certain fan

wheels are centered between the inlet openings and

setscrews are torqued per Table 14.

6 Check that the fan rotates freely. Check belt tension and

alignment.

7 Check that the unit condenser water connections and

condensate drain connections were made.

8 Before attempting to operate the unit, review the control

layout description to become familiar with the control

locations.

9 Review all equipment service literature and the unit wiring

diagrams supplied with each unit.

10 Review optional controls to determine which are included

in the unit.

11 Check that the return air temperature sensor (and optional

room sensor) is installed in the return air duct and that the

wiring terminations were made at the unit input board.

12 Check that entering and leaving condenser water

temperature sensors are mounted.

13 Check that the optional duct static pressure sensor is

connected to the duct with appropriate tubing. The unit may

have one optional static pressure sensor, SPS1. The other

option would be SPS1 and SPS2.

14 Check the voltage of the unit power supply and see that it is

within the allowed ±10% tolerance. Phase voltage

unbalance must be within ±2%.

15 Check the unit power supply wiring for adequate ampacity

and a minimum insulation rating of 75°C.

16 Verify that all mechanical and electrical inspections were

completed per local codes.

17 Open all liquid line service valves and tighten all packing

nuts

18 Open the compressor suction and discharge shutoff valves

until backseated. Always replace valve seal caps.

19 For units with compressor crankcase heaters: Make sure the

unit switch S1 is in the OFF position. Then throw the main

power disconnect to ON. This energizes the crankcase

heaters. Wait a minimum of 24 hours before starting the

unit.

WARNING

ELECTRIC SHOCK HAZARD

The equipment frame must be bonded to the building electrical

ground with the grounding terminal provided or other

acceptable means. Failure to properly ground can result in

electric shock, equipment damage, severe personal injury, or

death. Lock out and tag out all power sources to equipment

before servicing.

WARNING

Always open the power disconnect switch before opening

service panels. Failure to do so can result in electric shock,

equipment damage, severe personal injury, or death.

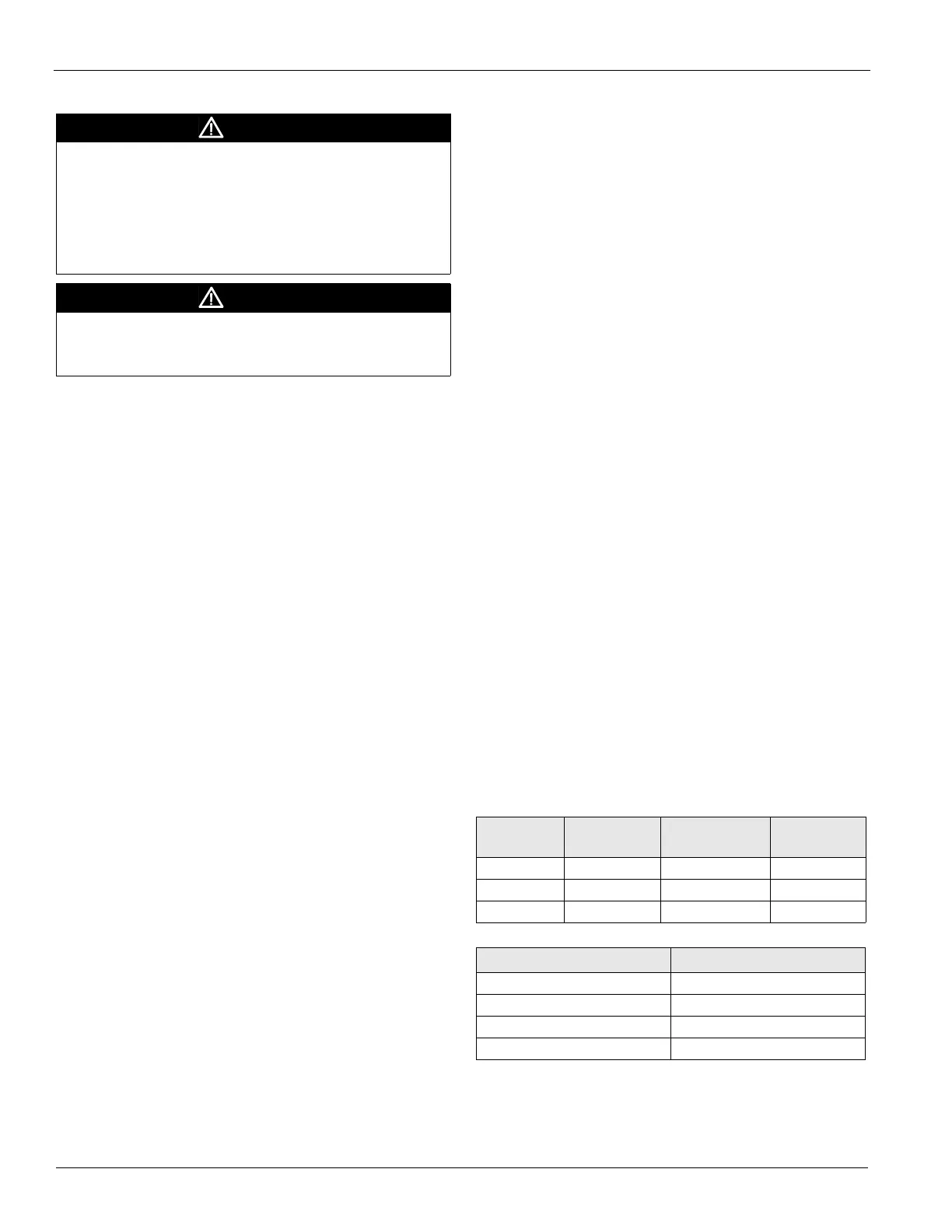

Table 13: Valve Torques

Coupling nut

size (in)

Gage port cap

torque (lbs-ft)

Stem cap torque

(lbs-ft)

Coupling nut

torque (lbs-ft)

1.00 7±1 32±2 55+5

1.25 7±1 32±2 90+10

1.75 7±1 45±3 205+15

Table 14: Setscrew Torque

Setscrew diameter Torque min. (ft.-lbs.)

#10 4.3

1/4” 10.0

5/16” 20.0

3/8” 25.0

Loading...

Loading...