Product Manual WHR-2 17

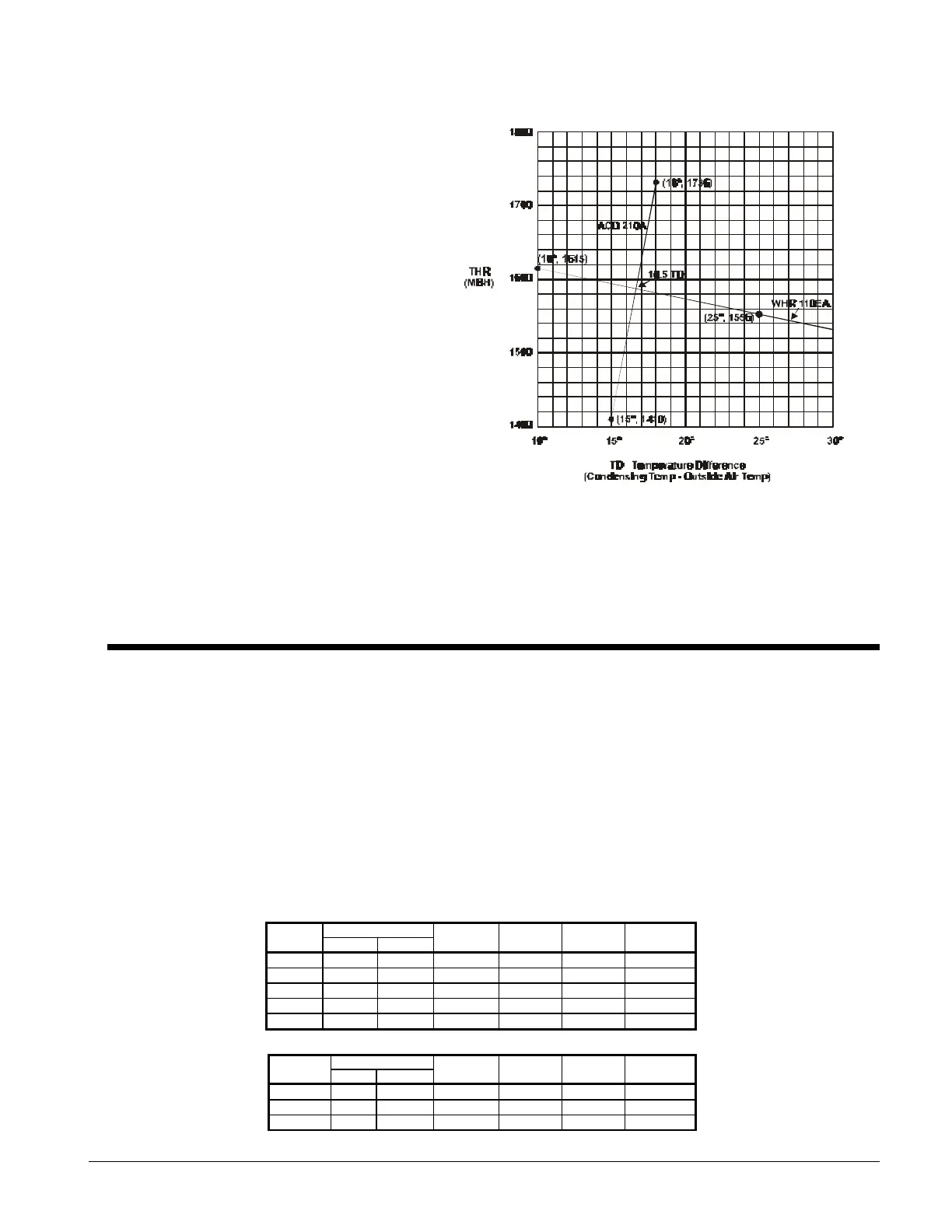

3) Graphical solution to Case a) is shown below.

d) The THR for the WHR

110EA is plotted using two

points; TD=10 degrees

(105°F-95°F) and TD=25

degrees (120°F-95°F).

e) The THR for the ACD 210A

is plotted using its capacity

at TD+15 degrees and

TD=18 degrees.

f) The curves intersect at

TD=16.5 degrees or 111.5°F

condensing temperature.

g) Extrapolating the WHR

capacity at 111.5°F gives

101.5 tons which will meet

the job requirements. It will

be the highest cost but

most efficient unit.

EA Remote Condenser, R-134a

Use the same selection procedures as with R-22 except multiply the values in the R-22 Performance

Tables as follows: Capacity x 0.68, Power x 0.65, EER x 1.05.

Selection Adjustment Factors

Ethylene and Propylene Glycol Factors

WHR units are designed to operate with a leaving chilled fluid temperature from 21°F (-6.1°C) to

60°F (16°C). Leaving chilled fluid temperatures below 40°F (4.6°C) result in suction temperatures at

or below the freezing point of water and a glycol solution is required. The use of glycol in the

evaporator will reduce the performance of the unit. The reduction in performance depends upon

the glycol concentration. This should be taken into consideration during initial system design.

McQuay encourages a minimum concentration of 25% be provided on all glycol applications.

Glycol concentrations below 25% are too diluted for long-term corrosion protection of ferrous

metals and corrosion inhibitors may need to be recalculated. Glycol in the condenser will have a

negligible effect on performance because glycol at higher temperatures will perform with

characteristics similar to water.

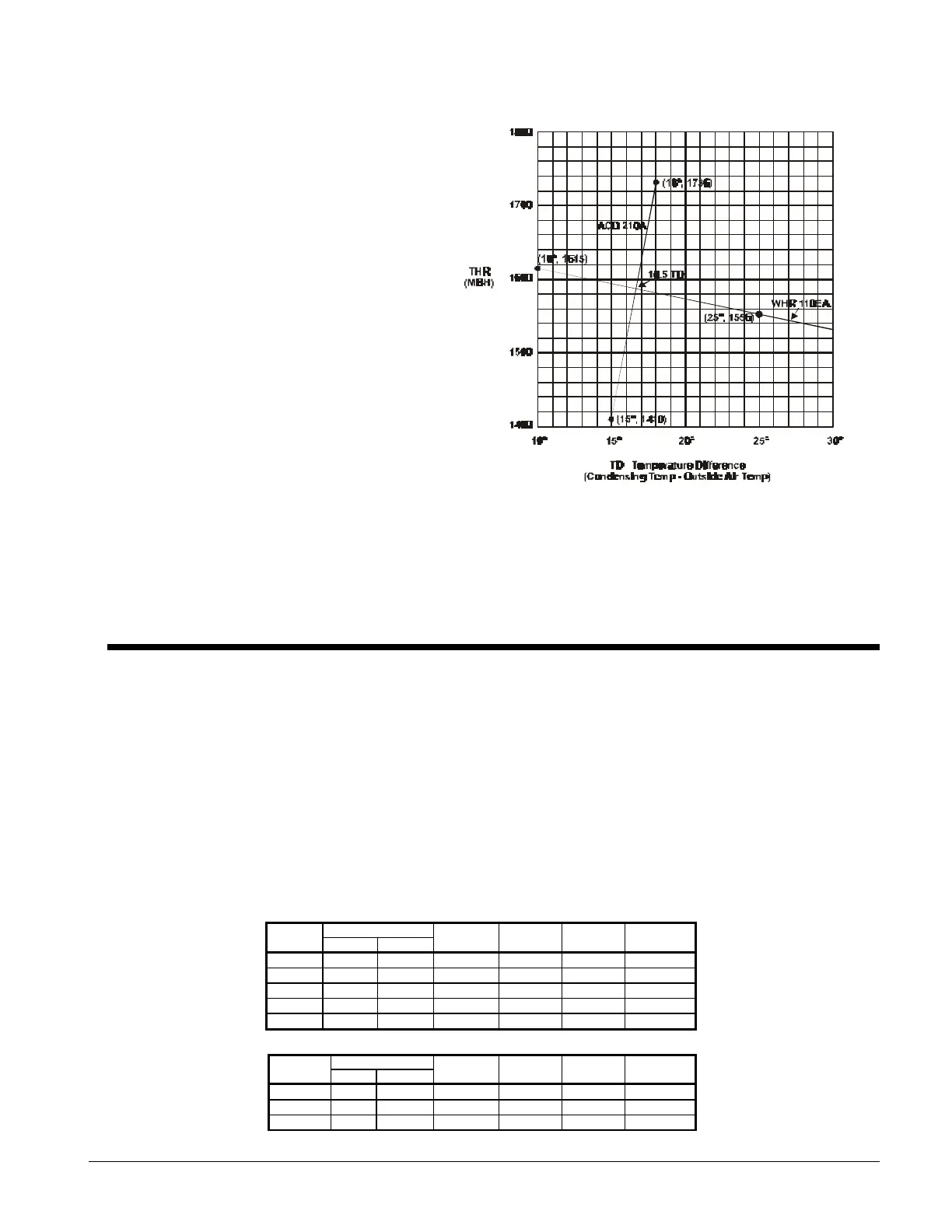

Table 1, Adjustment Factors for Ethylene Glycol

Freeze PointPercent

E.G

°F °C

Cap. Power Flow PD

10 26 -3 0.991 0.966 1.013 1.070

20 18 -8 0.982 0.992 1.040 1.129

30 7 -14 0.972 0.986 1.074 1.181

40 -7 -22 0.961 0.976 1.121 1.263

50 -28 -33 0.946 0.966 1.178 1.308

Table 2, Adjustment Factors for Propylene Glycol

Freeze PointPercent

P.G

°F °C

Cap. Power GPM PD

10 26 -3 0.987 0.992 1.010 1.068

20 19 -7 0.975 0.985 1.028 1.147

30 9 -13 0.962 0.978 1.050 1.248

Loading...

Loading...