6 Product Manual WHR-2

Design Advantages

Unit Arrangements

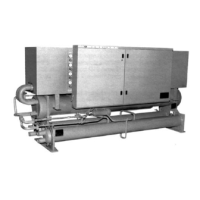

The McQuay water chillers are completely factory assembled, piped, wired and shipped in one piece,

ready for field connection of refrigerant (EA models) and water piping. Each unit consists of motor

compressors, insulated DX cooler and centralized electrical control panel containing all necessary

safety and operating controls, and compressor starting controls. Arrangement “EW” units come

complete with water-cooled condensers with integral subcooler circuits. Arrangement “EA” units are

provided without condensers to allow for remote installation of air-cooled or evaporative condensing

equipment.

Compressors

WHR chillers use Copeland DISCUS

semi-hermetic compressors. These compressors are designed

for R 22 and R-134a.

Semi-hermetic, 1750 rpm induction type motors are used. The motors are refrigerant gas cooled. Solid-

state modules in the motor terminal box respond to temperature sensors imbedded in all three motor

windings, providing inherent thermal overload protection for all run and start conditions.

The compressor housing is constructed from close grained, high nickel content, alloy cast-iron with

no bolted joint between the motor and compressor. The housing includes a cast-iron cylinder head

and stator cover, and a crankcase oil sightglass. A suction strainer built into the compressor in the gas

stream between the suction service valve and the motor, filters out foreign and abrasive particles. An

internal relief valve relieves discharge pressure to the suction side for safety protection at high

compression ratios as required by ANSI/ASHRAE 15 Safety Code.

Main bearings are solid cast bronze insert type with oversized bearing area resulting in ultra-low

bearing loading.

The crankshaft is die-forged, high strength iron alloy with integral counterweights, statically and

dynamically balanced for smooth operation.

Connecting rods are lightweight aluminum with integral bearing surfaces on the crankshaft and piston

ends. Pistons are close grain cast iron with oil and compression rings. Piston pins are full floating

type for long life.

Compressors have a forced-feed lubrication system with positive oil displacement, a reversible oil

pump, and an operating oil charge. The pump feeds oil through rifle-drilled passages in the crankshaft

to all bearing surfaces. Magnetic plugs trap particles that enter the crankcase. The oil supply filters

through a large area oil strainer. During start-up, a crankcase heater minimizes oil being diluted by

refrigerant.

Factory Installed Liquid Line Components

Each refrigerant circuit has a filter-drier, liquid line sightglass/moisture indicator, solenoid valve,

manual liquid line shutoff valve and thermal expansion valve.

Short Circuit Protection

(WHR 017 through 030, WHR 095 through 210)

Each compressor is individually protected against short circuit and locked rotor conditions by factory

installed circuit breakers. Separate fusing protects the control circuit. WHR-040 through 090 can have

circuit breakers factory installed as an option.

Loading...

Loading...