Product Manual WHR-2 7

Part Load Efficiencies

Part load efficiencies and Integrated Part Load Values (IPLV) for EW units are calculated according to

the requirements of the latest ARI Standard 550/590-98 and meet or exceed ASHRAE Efficiency

Standard 90.1. Since most air conditioning systems operate at less than design full load a majority of

the time, IPLV is an excellent method for comparing chillers' efficiencies.

Noise

All McQuay WHR chillers are equipped with hot gas discharge line mufflers in each refrigerant circuit

to reduce the overall sound levels. An optional insulated acoustical compressor enclosure to further

reduce sound levels is also available for most units. Sound level ratings are contained in the Sound

Rating section of this manual.

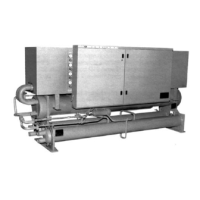

Unit Base

Designed for easy handling, the units are mounted on a compact, rugged formed steel base. Isolator

mounting holes are provided.

Electrical Control Center

Shipped with all operating and safety controls and motor starting equipment factory wired,

operationally tested, and ready for operation. All controls are centrally located in a hinged control

center with keylocked doors.

Part-winding starters are standard on 208/230 volt applications and available as a special on 460/575

volts. Across-the-line starters are standard on 380/460/575 volts.

A five-minute, solid-state lockout timer is provided to delay compressor restart after safety cutout or

power interruption, or under irregular cooling load demands. A lead lag switch is standard on all units

(WHR 040 – WHR 210) not incorporating the single circuit hot gas bypass option.

Evaporator

The evaporator is a direct expansion, shell-and-tube type with water flowing in the baffled shell side

and refrigerant flowing through the tubes.

The evaporator is constructed with a carbon steel shell and seamless high efficiency copper tubes,

roller expanded into heavy carbon steel tube sheets. Water baffles are polypropylene to resist

corrosion.

Refrigerant heads are carbon steel with multi-pass baffles to ensure oil return and are removable to

permit access to the tubes from either end. For water removal, 3/8" (10mm) vent and drain plugs are

provided on the top and bottom of the shell. Two 1/2” (12.7mm) couplings on each water nozzle allow

for easy field installation of sensor equipment.

The evaporator is wrapped with 3/4” (19.1mm) thick vinyl nitrate polymer sheet insulation. The

insulation has a K factor of 0.28 at 75°F (24°C). The insulation is fitted and cemented in place, then

painted with a resilient vinyl base paint to resist cracking.

The tube side maximum working pressure is 225 psig (1552kPa). The waterside working pressure is 175

psig (1206kPa). All evaporators are designed, constructed, inspected and stamped according to the

requirements of the ASME Boiler and Pressure Vessel Code.

Loading...

Loading...