MEA INC

2600 American Lane | Elk Grove Village, IL 60007 | USA

T +1 847 766 9040 | F +1 847 350 1951

COMPLETE CONTROL

www.meaincorporated.com

MEA Incorporated | Hawk Actuator Instruction and Operation Manual

02/2018

17

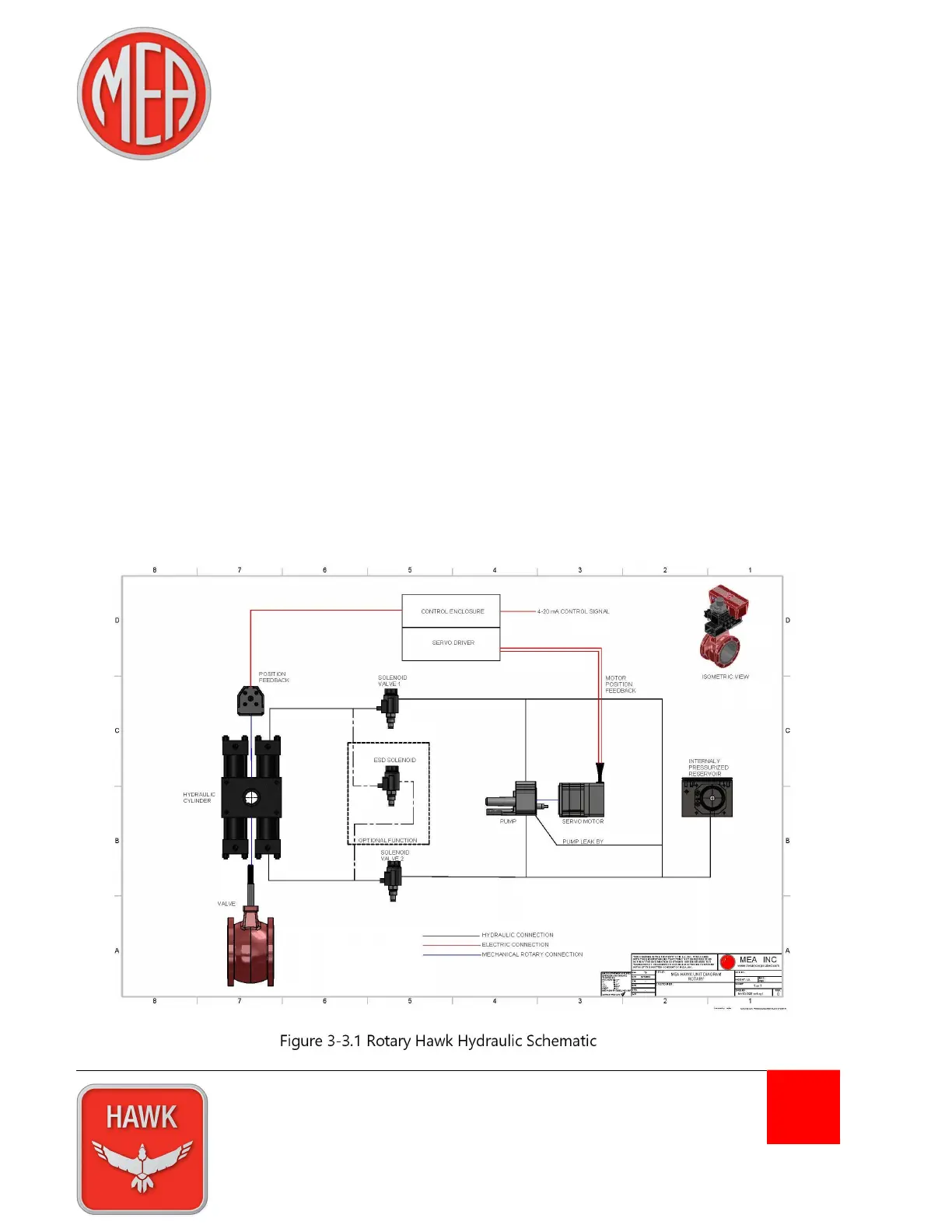

3-3 Rotary Actuator

The rotary version of the Hawk actuator consists, depending on required torque output, of either one or

two double-acting, equal displacement cylinders which in combination with a rack and pinion linkage and

pressurized fluid from the HPS, creates rotary movement of the driven device. In Control mode, the

actuator receives a desired position signal from the DCS. This signal is compared to the current position

signal provided by the actuator’s position feedback. The difference between the desired position and

current position is the deviation. If this deviation exceeds the user defined deadband the servo driver

begins the process of moving the actuator by first energizing the motor, which in turn spins the pump.

For a brief period, less than 80 ms, the pump builds pressure in the system before the solenoids are

energized. Once sufficient system pressure is generated, the solenoids open and the hydraulic fluid

moves the cylinders and the driven device.

Ultimately, the actuator will rotate the driven device in the direction that will decrease the deviation to 0%

± the deadband. Once reaching this position the servo motor and solenoids will de-energize and the

actuator will remain in place until the next deviation occurs.

Figure 3-3.1 Rotary Hawk Hydraulic Schematic

Loading...

Loading...