"2033ES / 2633ES" Service & Parts Manual - ANSI Specifications October 2008

Page III

GENERAL SAFETY TIPS

Regular inspection and conscientious maintenance is the key to efficient economical operation of

your scissor lift. It will help to assure that your equipment will perform satisfactorily with a mini-

mum of service and repair.

The actual operating environment of the machine governs the inspection schedule. Correct lubri-

cation is an essential part of the preventative maintenance to minimize wear on working parts

and ensure against premature failure. By maintaining correct lubrication, the possibility of me-

chanical failure and resulting downtime is reduced to a minimum.

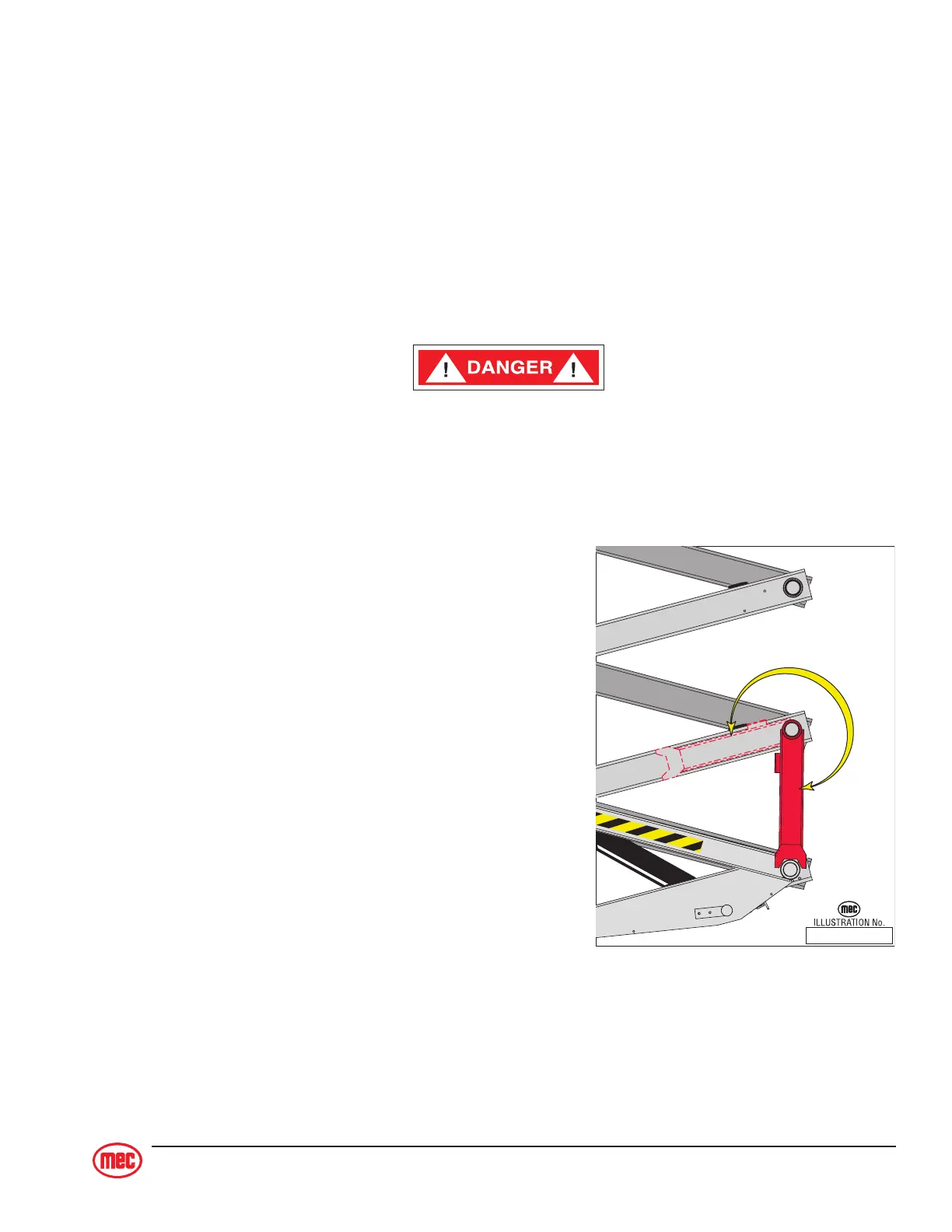

NEVER PERFORM SERVICE ON THE MACHINE (WITH THE

PLATFORM ELEVATED) WITHOUT FIRST BLOCKING THE SCISSOR

ASSEMBLY IN PLACE USING THE MAINTENANCE LOCK!

♦ Block scissor assembly using Maintenance Lock if

machine is in the elevated/extended position.

♦ Never leave hydraulic components or hoses open.

They must be protected from contamination (includ-

ing rain) at all times.

♦ Never open a hydraulic system when there are

contaminants in the air.

♦ Always clean the surrounding area before opening

hydraulic systems.

♦ Use only recommended lubricants. Improper lubri-

cants or incompatible lubricants may be as harmful

as no lubrication.

♦ Watch for makeshift “fixes” which can jeopardize

safety as well as lead to more costly repair.

ART_2152

Loading...

Loading...