Page 18 Micro 26 - Service & Parts Manual

April 2019

Calibration Instructions

The Platform Overload Sensing System may require calibration in the event of a malfunction or

after the replacement of an Overload System component. Proper and correct calibration of the

Overload system is critical for normal and trouble-free machine operation. Read and understand the

instructions before beginning the calibration process.

Calibrate Tilt Sensor

Park the machine on flat level surface.

Note: Calibrating the level sensor requires that the machine be

perfectly level on both the X and Y axis. An inclinometer

should be used when ensuring level. Machine power must

be on.

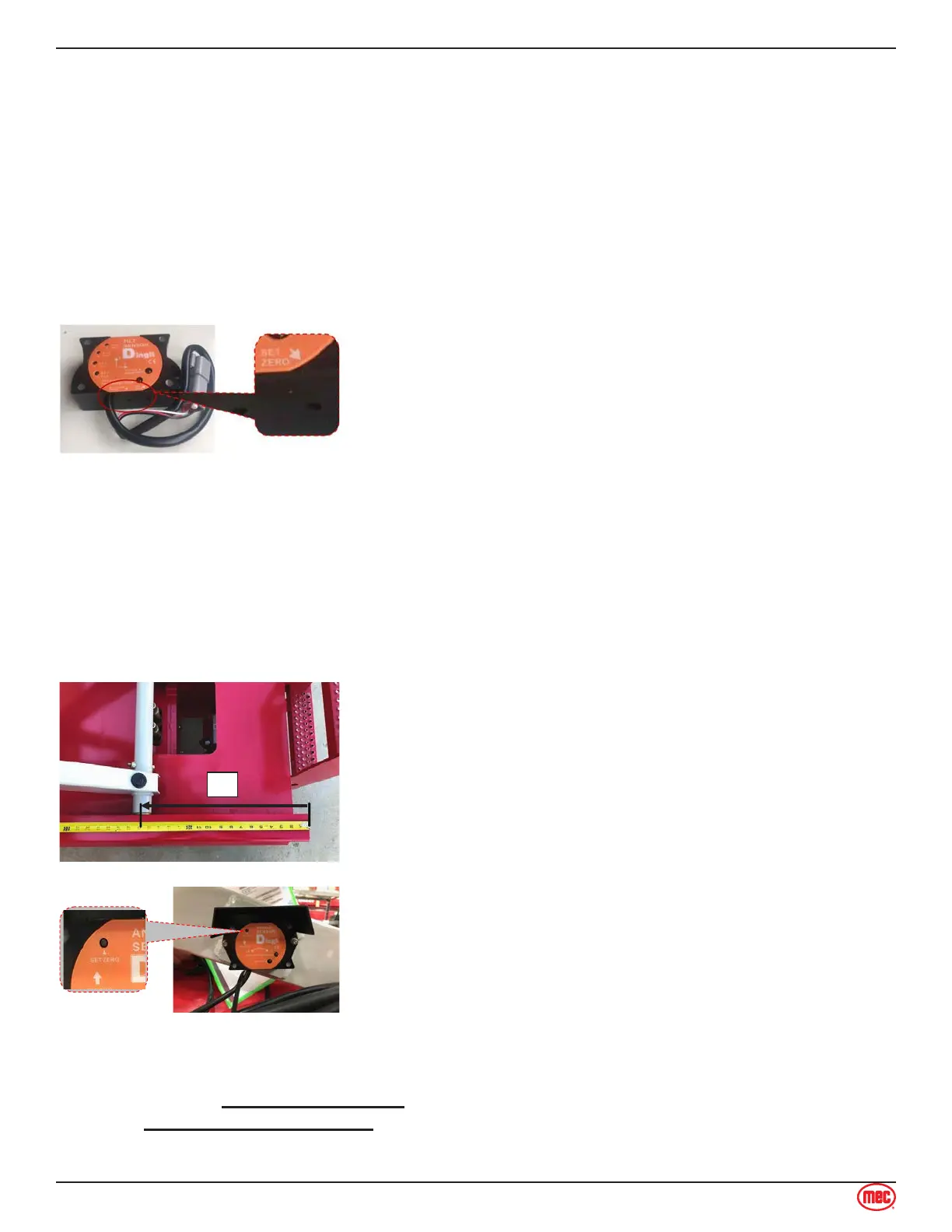

Using the diagram below, locate the “SET ZERO” button

located on the side of the sensor. Press and hold the “SET

ZERO” button until the LEDs alternate red and green flashes.

Release the button

Press the “SET ZERO” button three times. The LEDs will

turn off then only the green LED will illuminate, Calibration is

complete.

1.

2.

3.

Calibrate Height Sensor

Note: Calibrate Overload System must be performed after calibrating height sensor to ensure proper

and trouble-free machine operation.

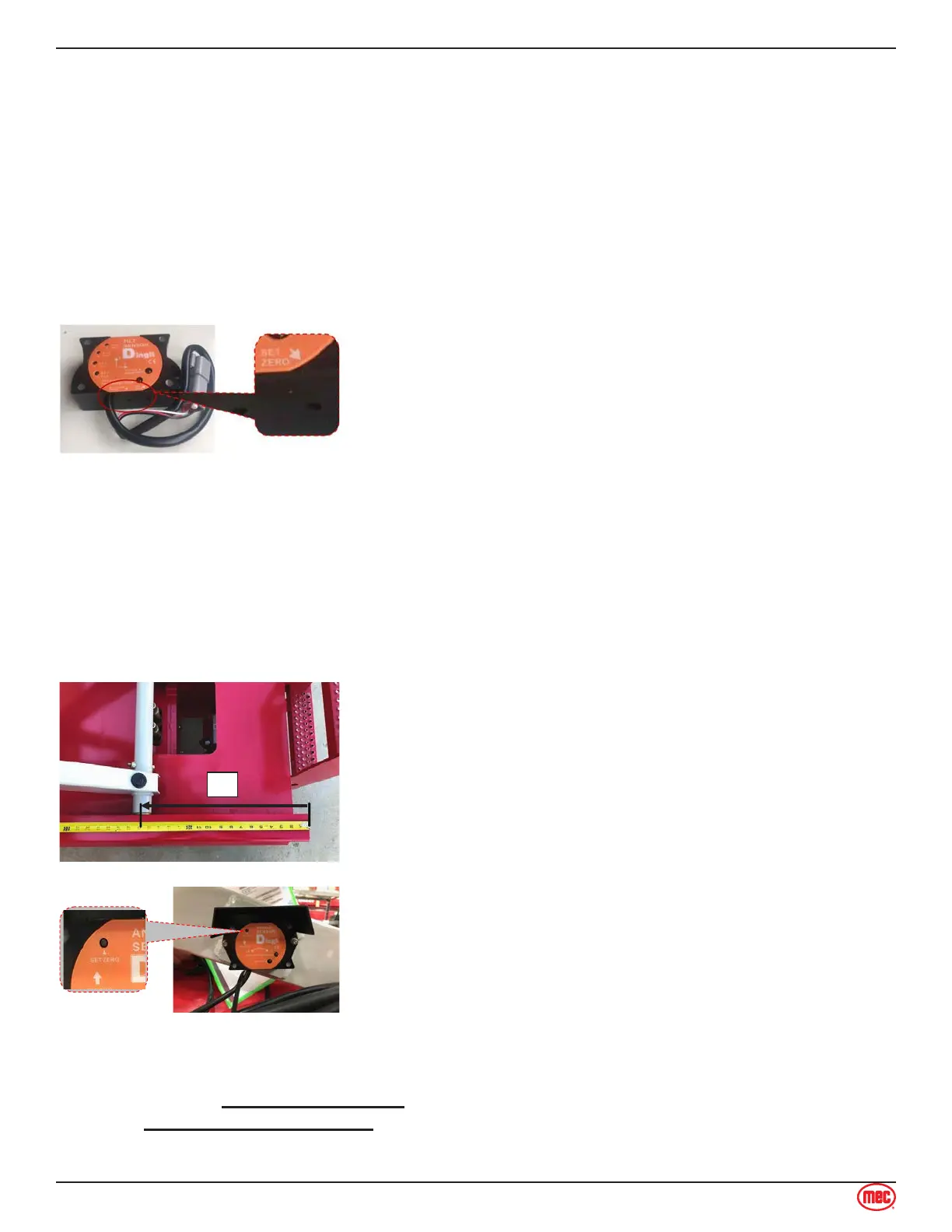

Refer to the diagram below. Elevate the platform until the

round scissor tube is exactly 17” from the end of the slide

channel, measuring on the top of the slide channel.

Referring to the following diagram, locate the height sensor,

located inside the scissor beams. Press and hold the “SET

ZERO” button until the two LEDs alternate red and green

flash alternately. Release the button.

Press the “SET ZERO” button three times. If done correctly,

the red light will flash followed by the green light flash

followed by the green light illuminating solid. HEIGHT

CALIBRATION COMPLETE.

1.

2.

3.

Calibrate Overload System

Note:

The platform will lift automatically once the calibration has been initiated. Be sure that there

are no overhead obstructions when choosing a location on which to calibrate the overload

system.

Section 10 - Calibration Instructions

Calibration Instructions

Loading...

Loading...