Page 31 Micro 26 - Service & Parts Manual

April 2019Section 11 - Maintenance

listed on the Annual Inspection Report. See specific instructions below.

Scissor Slide Blocks

Maintaining the condition of the scissor arm slide blocks is essential to safe machine operation.

Continued use of worn out wear pads may result in component damage and unsafe operating

conditions.

Perform this procedure with the platform in the stowed position.

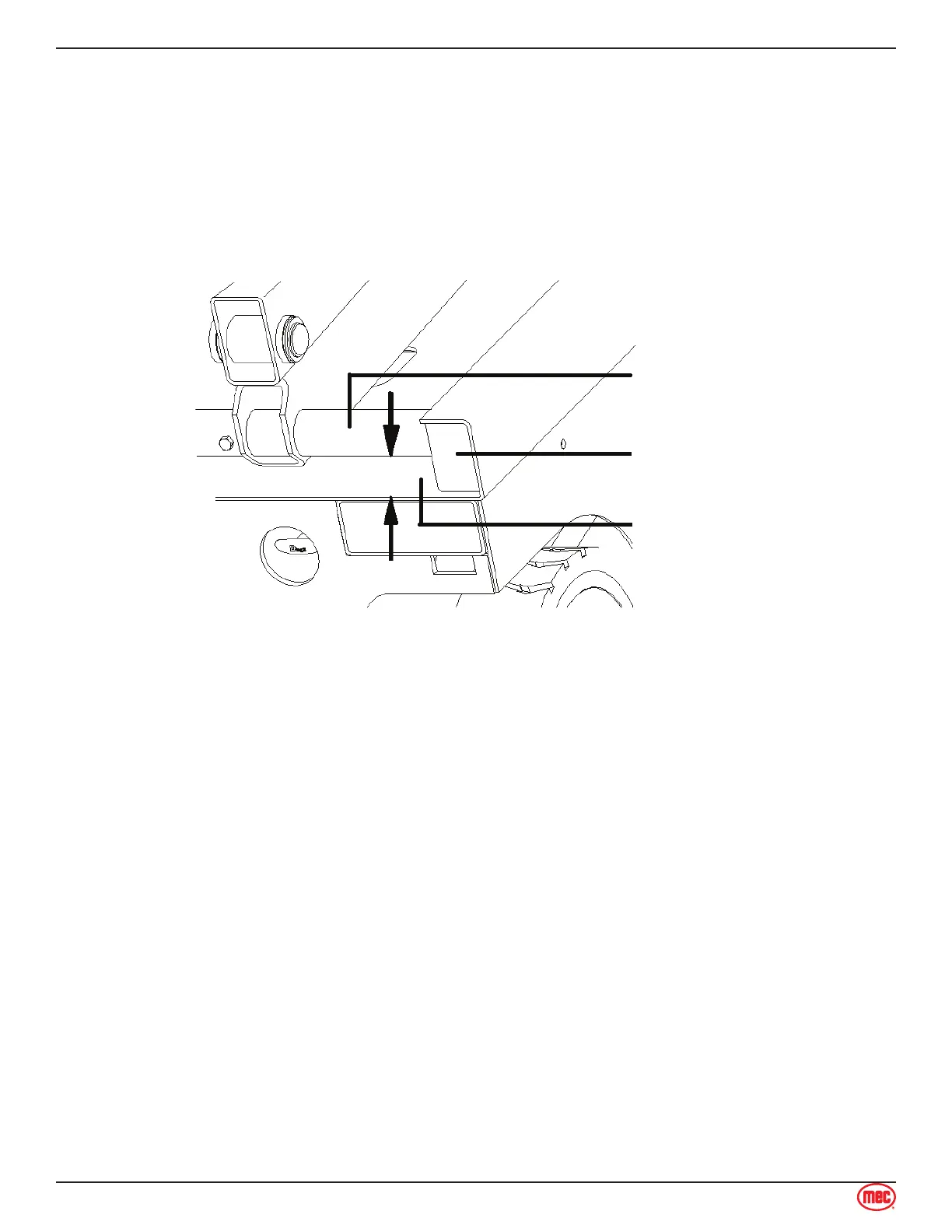

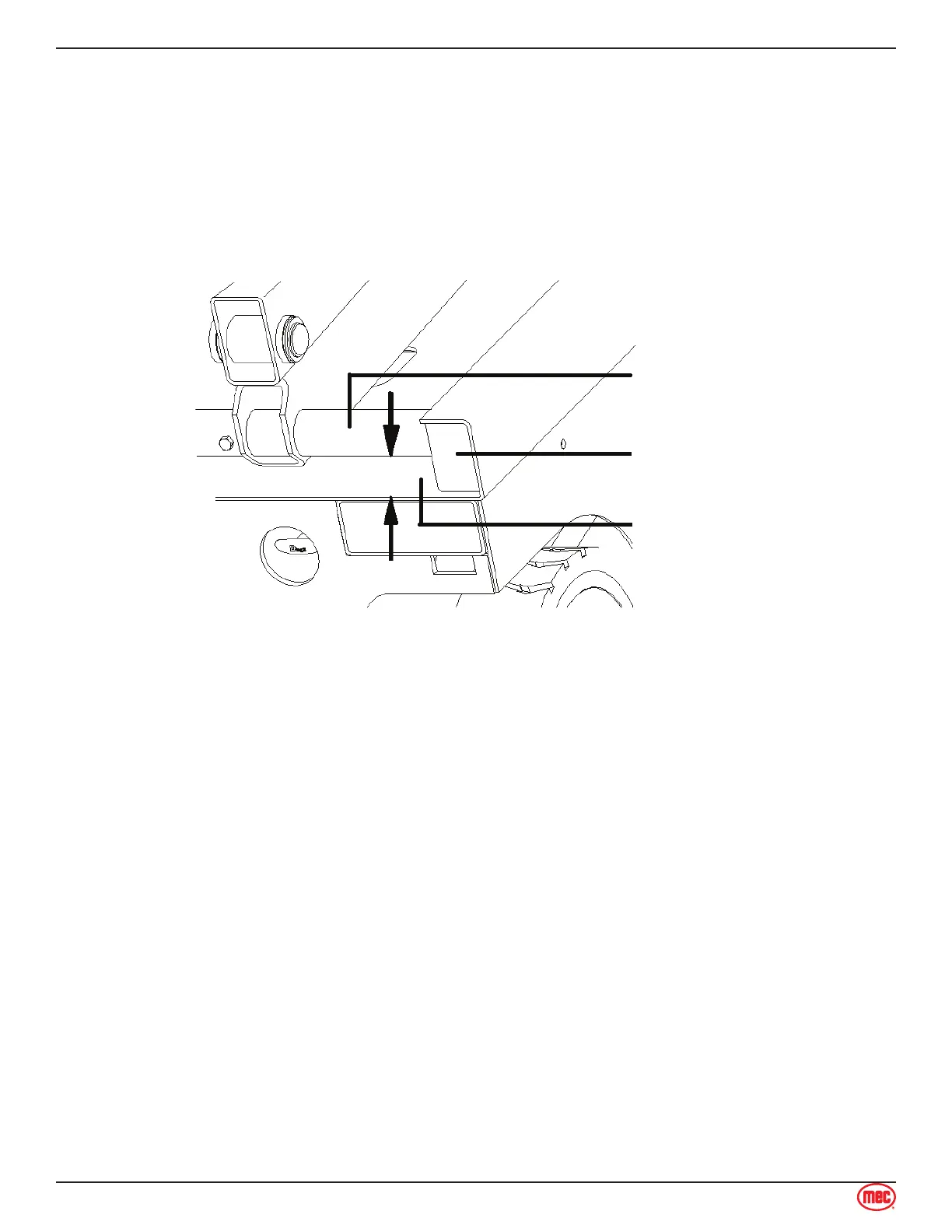

ART_5122

Slide Block

Inner Arm

Cross Tube

Chassis Deck

Measure the distance between the number one inner arm cross tube and the chassis deck at the

ground controls side of the non-steer end of the machine.

Result: The measurement is 1.34 in / 34 mm or more. Proceed to step 2.

Result: The measurement is less than 1.34 in / 34 mm. Replace both slide blocks.

Measure the distance between the number one inner arm cross tube and the chassis deck at the

battery module side of the non-steer end of the machine.

Result: The measurement is 1.34 in / 34 mm or more. Proceed to step 3.

Result: The measurement is less than 1.34 in / 34 mm. Replace both slide blocks.

Apply a thin layer of dry film lubricant to the area of the chassis where the scissor arm wear pads

make contact.

Hydraulic Tank Breather Cap

The hydraulic tank is a vented-type tank. The breather cap has an internal air filter that can become

clogged or, over time, can deteriorate. If the breather cap is faulty or improperly installed, impurities

can enter the hydraulic system which may cause component damage. Extremely dirty conditions may

require that the cap be inspected more often.

Remove and discard the hydraulic tank breather cap.

Install a new cap onto the tank.

Hydraulic Oil Inspection/replacement

1.

•

•

2.

•

•

3.

1.

2.

Loading...

Loading...