MAC/MTT-OPS-1

26 FEB 2019

SECTION 2

System Description

2-3

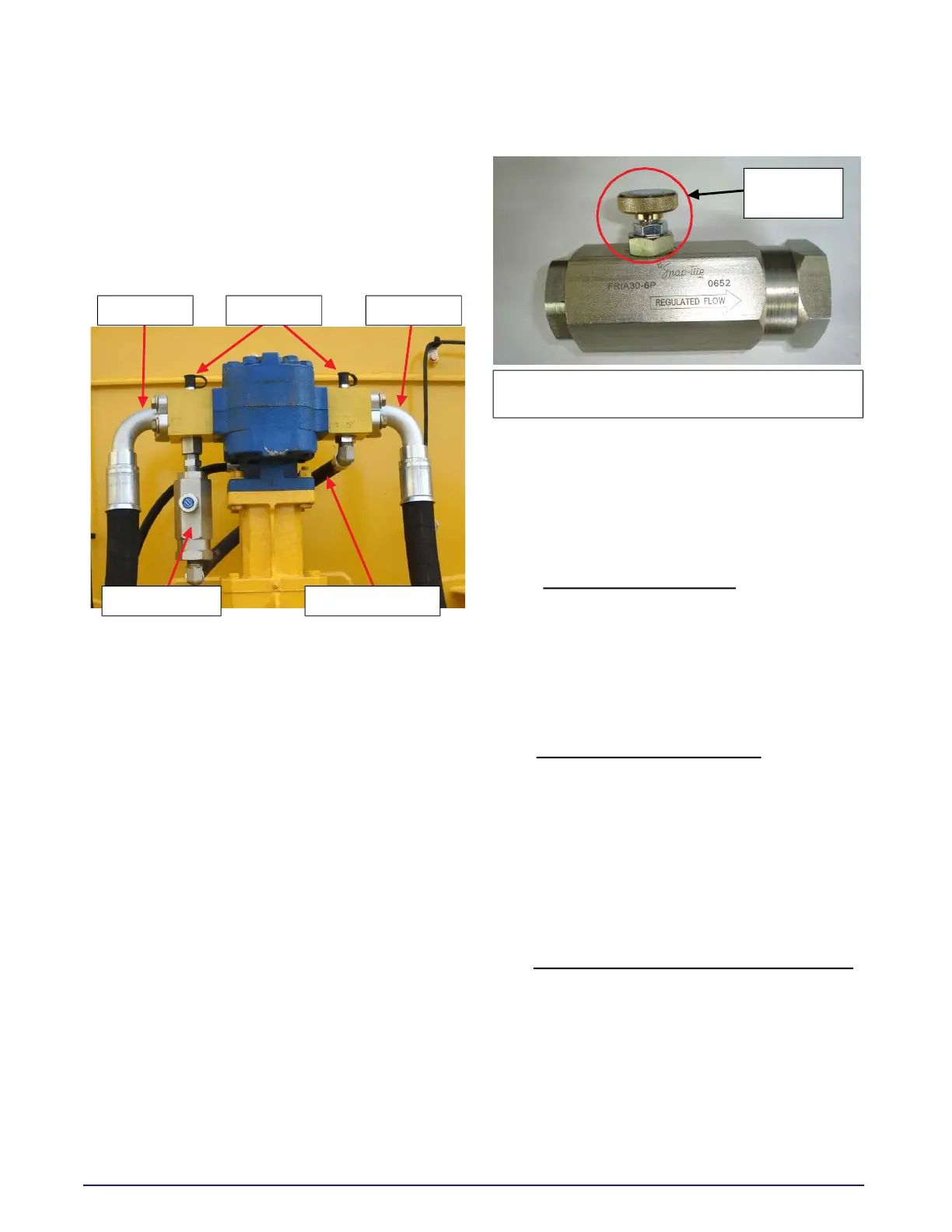

Hydraulic Drive Motor Speed Control

(Crossover Assembly)

The hydraulic drive motor speed control

(Crossover Assembly) consists of a flow control

valve, 2 hydraulic manifolds, crossover hose and

test ports.

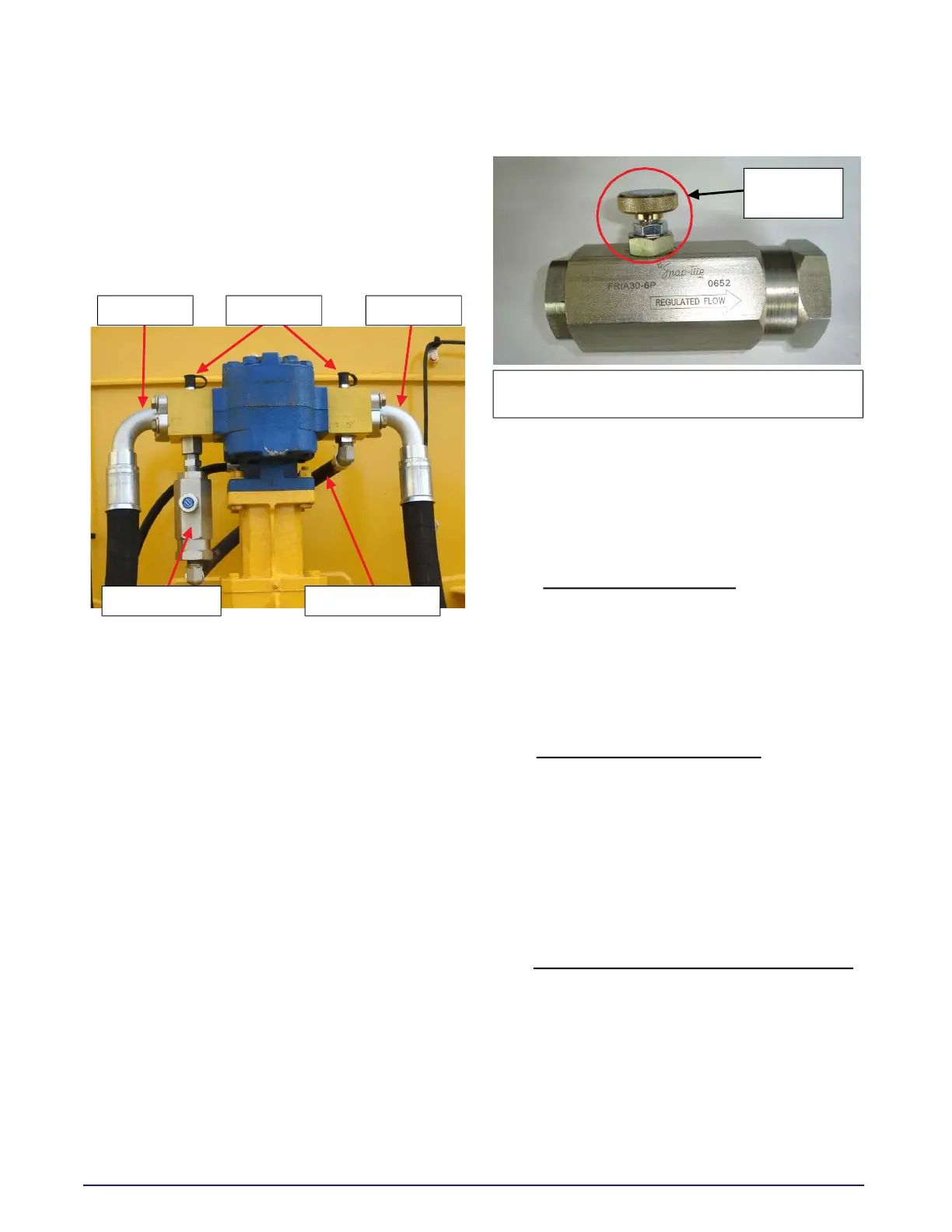

Hydraulic Flow Control Valve

The hydraulic flow control is directional. The arrow

on the body indicates the direction of oil flow to

meter the bypassing oil. The adjusting knob on the

valve will allow adjustment of the oil flow to

bypass the drive motor, up to135 LPM (35 GPM) or

up to 700 RPMs (RPM increase/decrease will vary

depending on the size of hydraulic drive motor the

unit is equipped with).

If the flow control is reversed, the flow control

adjusting knob will not function and the full flow

capacity of the valve will bypass. This can result in

water pump rpm being below specifications with

no adjustment capability of the adjusting knob.

By turning the adjusting knob clockwise, the

hydraulic oil that is bypassing will be reduced,

increasing the speed of the water pump. Turning

the knob counter-clockwise will increase the

volume oil being bypassed reducing the water

pump speed. The flow control valve is typically

mounted on the PRESSURE manifold of the

hydraulic drive motor.

Hydraulic Drive Motor Activation

The hydraulic drive motor on MTT’s are typically

driven by the chassis hoist hydraulic system. The

activation can be controlled by the following:

– Existing Electric Hoist Valve

The MEGA cab control pump switch commands

the hoist valve to operate by sending an electric

signal to the electric solenoid on the hoist valve.

This operates the hoist valve, diverting the

hydraulic oil to the water pump drive motor.

– Pilot Operated Diversion Valve

A remote mounted diversion valve that receives

an electric signal from the cab control pump

switch to activate a pilot control to move a

spool within the diversion valve redirecting the

hydraulic oil to flow to the water pump drive

motor. Typically this type of valve is installed

between the hoist pump and the hoist valve.

– Existing Mechanically Operated Hoist Valve

Typically used on early model trucks with a

pneumatic system. This system is operated by

the cab control pump switch sending an electric

signal to an electric/pneumatic solenoid to

control a pneumatic cylinder. When the

pneumatic cylinder operates it moves the spool

valve of the hoist valve to divert hydraulic oil to

the water pump drive motor.

PRESSURE RETURNTEST PORTS

FLOW CONTROL CROSSOVER HOSE

Typical 135 lpm (35 gpm) Adjustable Hydraulic

Flow Control

ADJUSTING

KNOB

Loading...

Loading...