10

Test vessel mortised stirrer

Unpack the optional motorised stirrer assembly from its box and fit the stirrer shaft to the underside of the stirrer

assembly. The unit is ready for use. The oil test vessel lid is removed and the stirrer assembly used as a lid for tests that

require stirring.

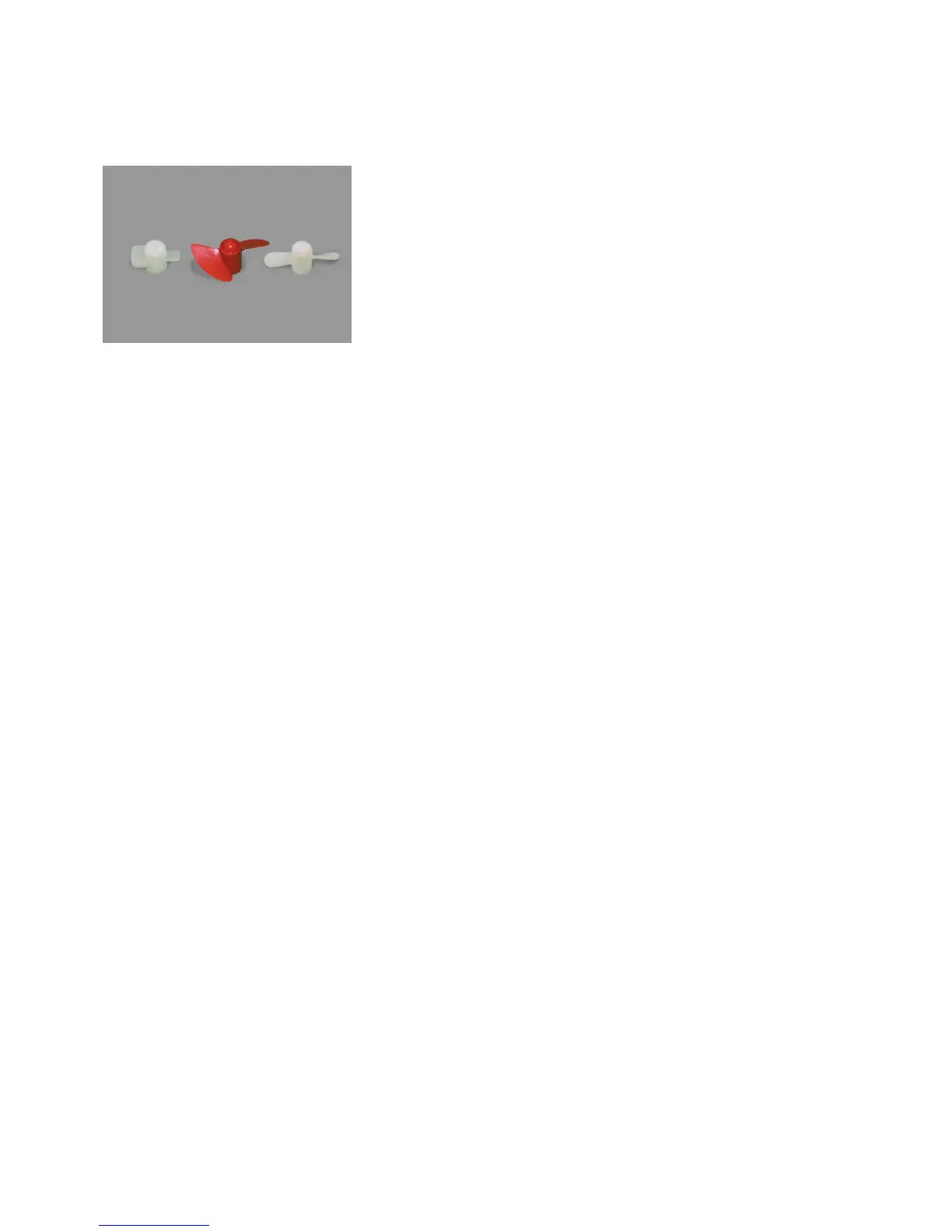

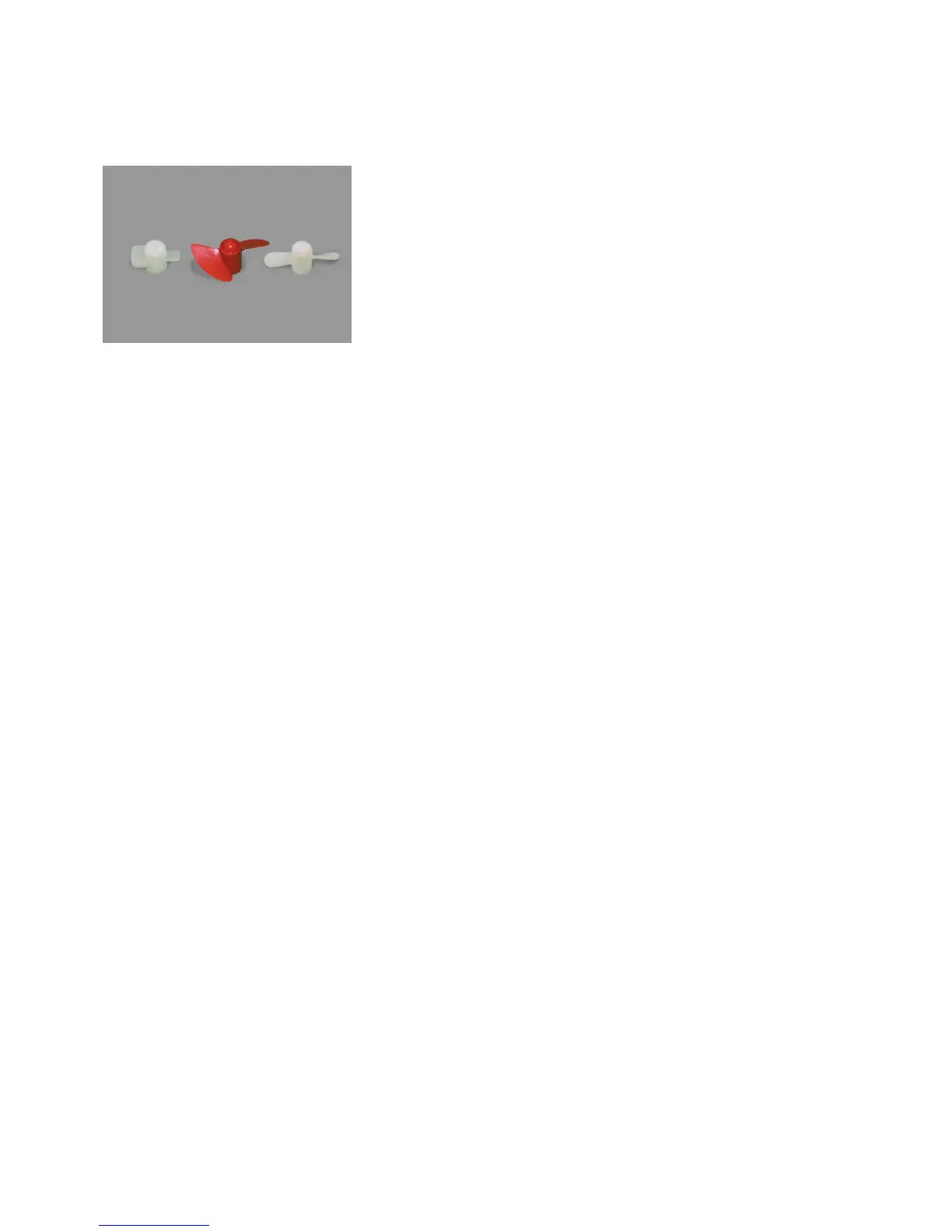

Megger supplies as standard with the stirrer lid assembly the large red impeller which is useful for very dirty oil. This has

larger blades to help ensure the effective circulation of any particulates between the electrodes during the test so that

the full potential of their effect on breakdown voltage may be assessed.

The other two impellers are alternative impellers. The Impeller on the left is optimised for IEC 60156, whilst the one on

the right is ideal for ASTM D1816.

Vigorous circulation can exacerbate the inclusion of any moisture captured on the surface film of oil left behind after

rinsing at the vessel preparation stage, making the need for rapid filling even more critical, so as not to detrimentally

affect breakdown results.

Refer to application note ref “OTS_VESSEL_AN_en” for further information on vessel and impeller preparation.

Note: this colour highlighted text from OTS vessel app note

Transportation and storage

The OTS100AF/80AF/60AF are precision instruments that generates HV up to 100 kV depending on model and needs

to be transported and stored carefully.

The unit should be stored in a room or area where the environment is within the temperature range of -30 ºC to 65 ºC

and maximum humidity of 95% at 45 ºC.

Loading...

Loading...