16

Print quality and changing paper

The printer cover is removed by turning the two fasteners through a quarter turn and pulling the panel off.

The printer ribbon may need to be moved on to improve print quality. To do this, remove the printer cover and turn the

right hand rotary winder in direction indicated on the ribbon case.

To change the printer ribbon, simply press the ribbon assembly where it says, “PUSH EJECT,” to remove the old ribbon

and replace with a new one. The part is an Epson ERC-09, Megger part number 25995-002.

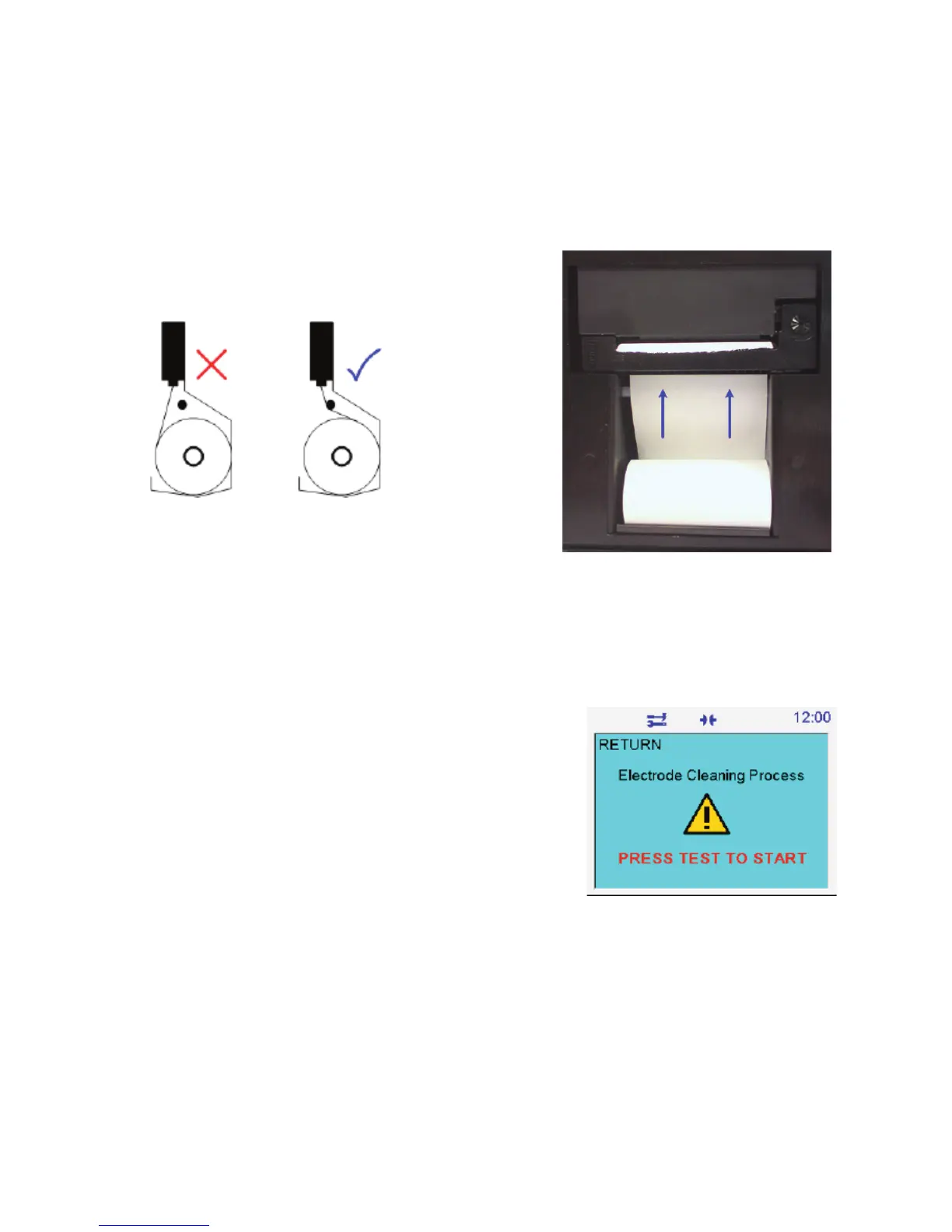

Paper is fed into the housing with the lose paper facing the rear of the instrument. Ensure that the paper is neatly cut

and not curled up at the end.

Holding the end of the paper roll, insert the paper under the cross bar and into the printer slot as shown (blue arrows)

in the drawing opposite. Press the print feed key repeatedly until the paper is just visible feeding through the print

mechanism.

Replace the printer front cover by first locating it at the base of the panel and secure it with the fasteners which are

turned back a quarter turn to secure the panel in place. Finally press the paper feed button to advance the paper

through the front cover paper slot.

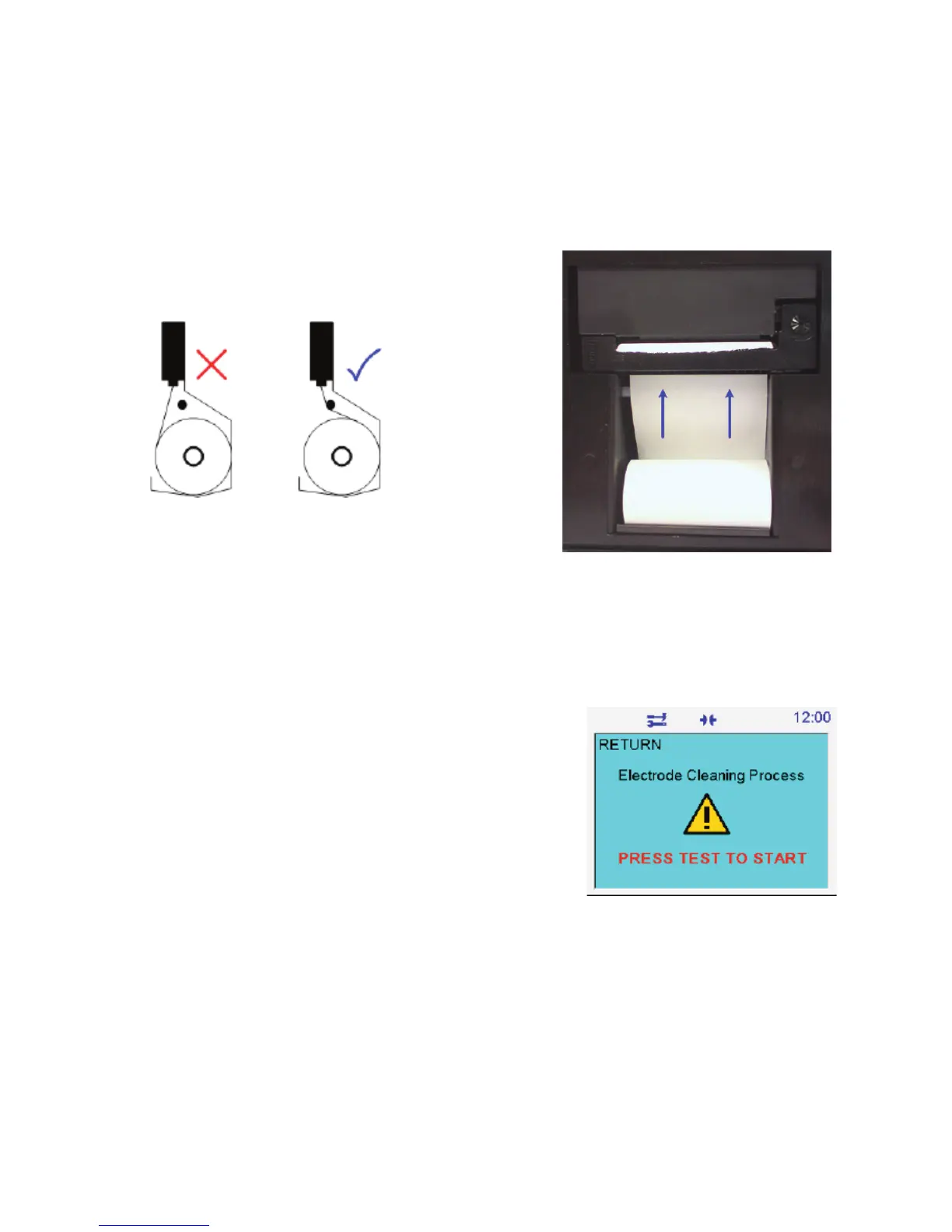

Vessel and Electrodes

The oil test vessel and electrodes require no maintenance other than

cleaning. Electrodes can be unscrewed and replaced with another shape

electrode. Electrodes should be examined regularly to ensure no pitting has

occurred and the electrodes renewed where pitting is evident.

VCM100D/VCM80D

The VCM100D/VCM80D is not a user serviceable items but may require periodic cleaning using a clean cloth dampened

with Isopropyl Alcohol (IPA).

Test vessel motorised stirrer

Megger’s motorised stirrer is integrated into a modified lid assembly and simply replaces the vessel lid. Power is

connected via a flush mounted rear insert and is disconnected as the stirrer assembly is lifted. This unit is not user

serviceable.

Loading...

Loading...