7-2

EP 1 Operation Manual Melco Embroidery Systems

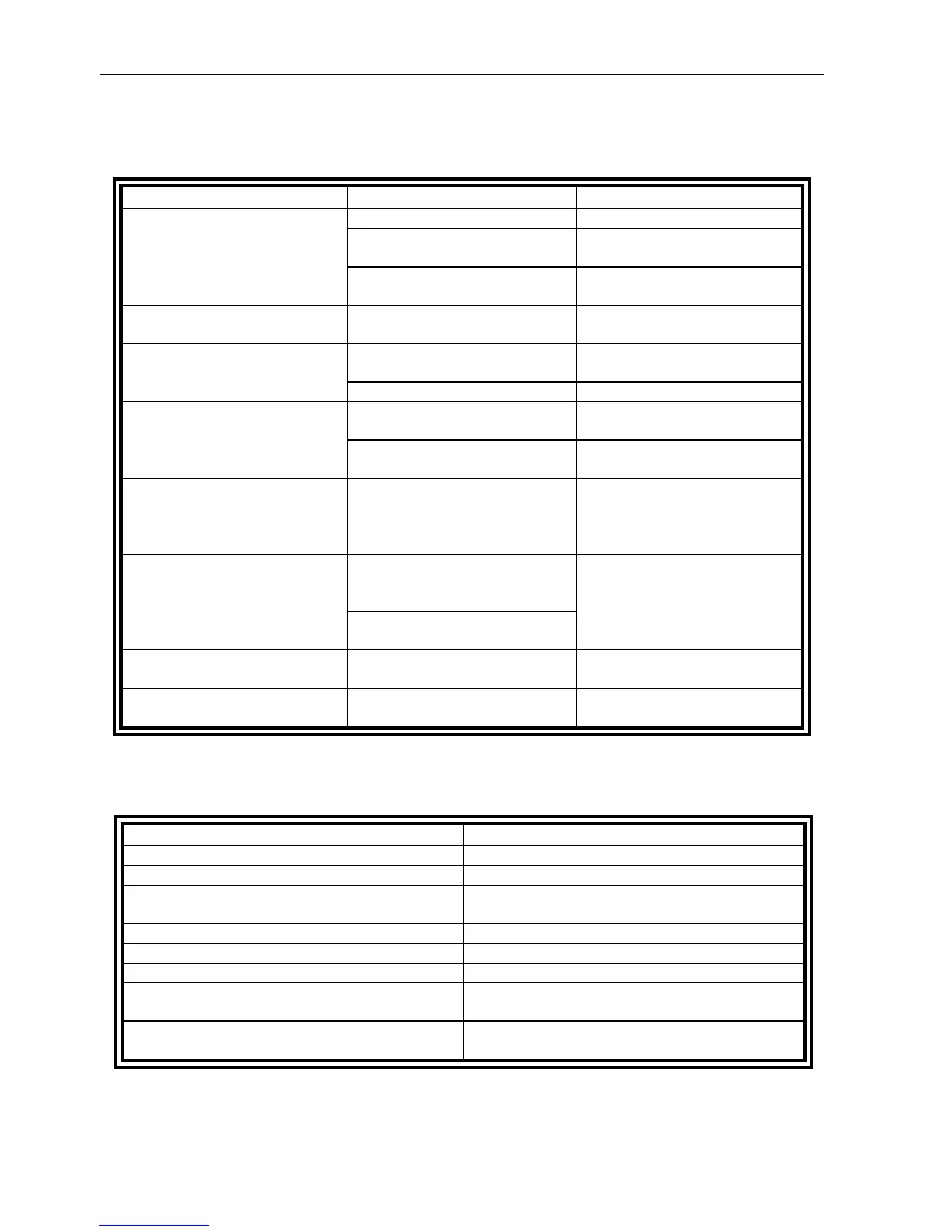

Skipped stitches

Needle breaks

POSSIBLE CAUSES

Needle is bent or damaged

Incorrect needle for the thread

size being used

Replace with a compatible

Needle is installed incorrectly

Install needle correctly (see

needle replacement section)

Needle bar lowest dead point is

Adjust needle depth (refer to

Hook timing is incorrect

Bobbin thread does not feed

Replace the bobbin and/or

Upper thread does not feed out

Adjust the upper tensions

A weak or broken presser foot

Replace or strengthen the

spring (refer to the technical

Thread twist is too tight

Use the appropriate thread or

consult the service department

Thread is too elastic to form an

The check spring stroke is too

high

Adjust the check spring stroke

(refer to the technical manual)

The check spring tension is too

Needle installation is incorrect

Install correctly (see needle replacement section)

Needle strikes the rotary hook

Adjust hook timing refer to the technical

Needle is too small for the fabric

Replace with compatible needle

Needle strikes the needle plate

Adjust position of the needle case (refer to the

Reposition the UTC (refer to the technical

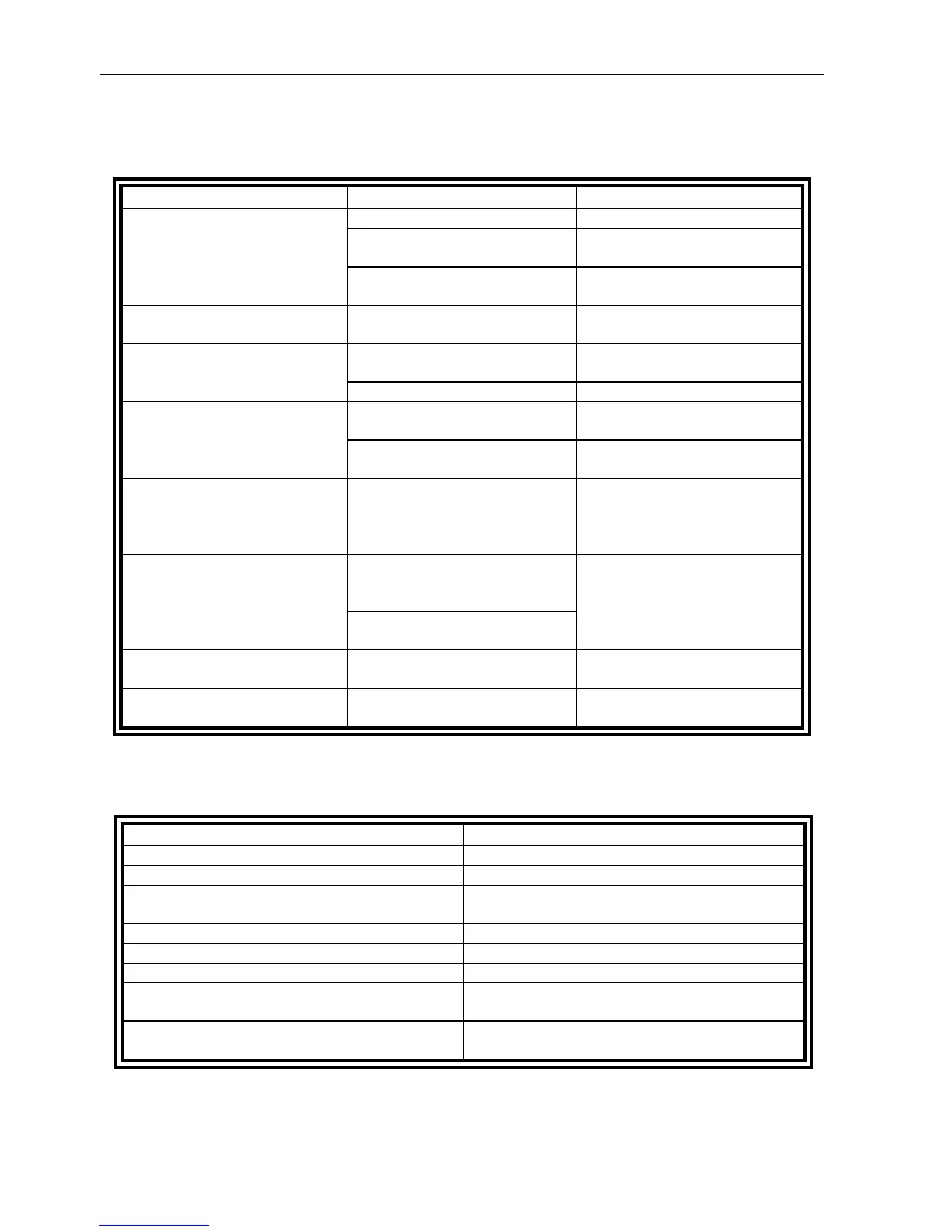

Loading...

Loading...