OUTBOARD INSTALLATION

83

Description Nm lb. in. lb. ft.

Access cover bolt 10 89

Propeller Installation

PROPELLER INSTALLATION - 108 MM (4-1/4 IN.) DIAMETER GEARCASE

!

WARNING

Rotating propellers can cause serious injury or death. Never operate the boat out of the water with a

propeller installed. Before installing or removing a propeller, place the drive unit in neutral and engage

the lanyard stop switch to prevent the engine from starting. Place a block of wood between the

propeller blade and the anti-ventilation plate.

1. Coat the propeller shaft with Quicksilver or Mercury Precision Lubricants Anti-Corrosion Grease

or 2-4-C Marine Lubricant with Teflon.

Tube Ref No. Description Where Used Part No.

94

Anti-Corrosion Grease Propeller shaft 92-802867 Q1

95

2-4-C Marine Lubricant with

Teflon

Propeller shaft 92-802859Q1

IMPORTANT: To prevent the propeller hub from corroding and seizing to the propeller shaft (especially

in salt water), always apply a coat of the recommended lubricant to the entire propeller shaft at the

recommended maintenance intervals, and also each time the propeller is removed.

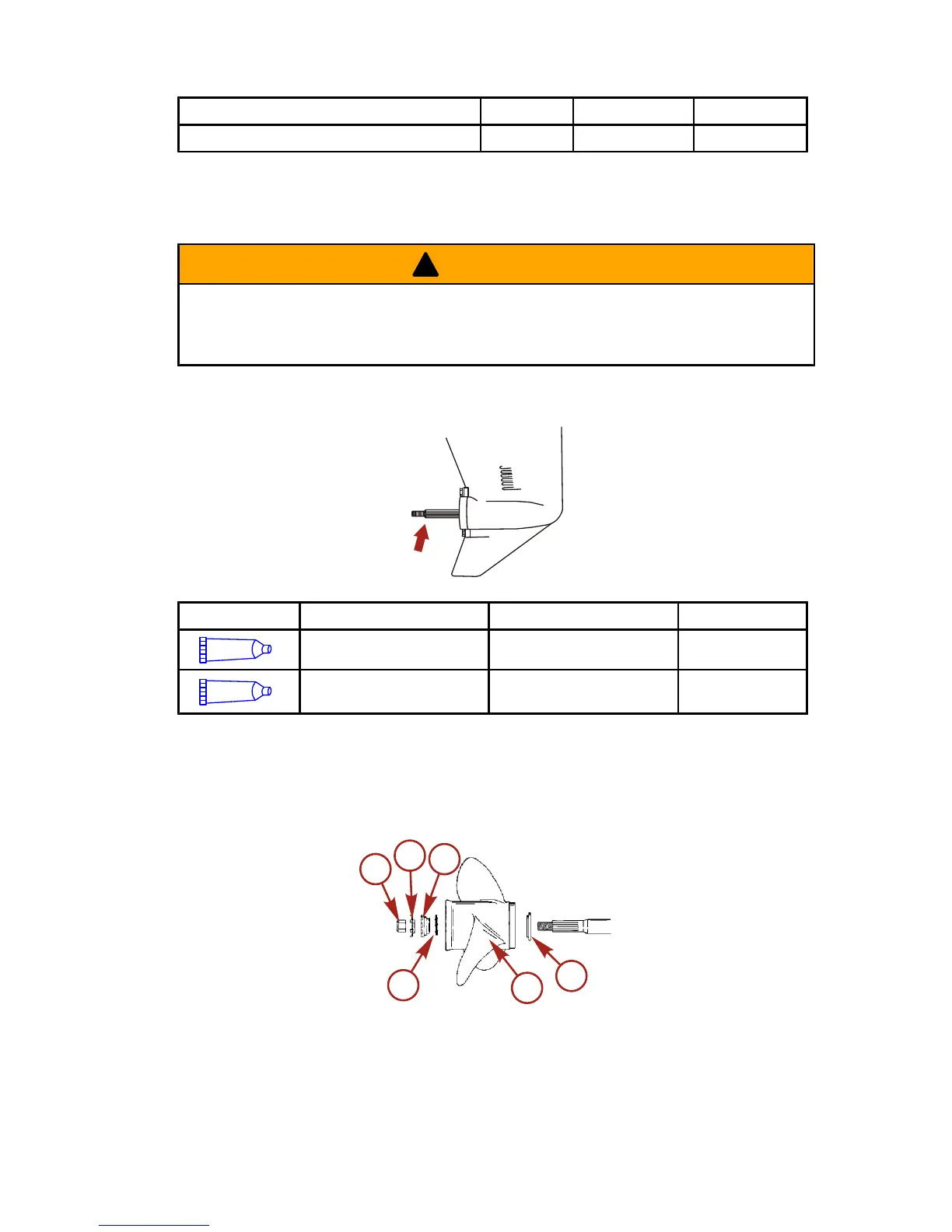

2. Flo-Torq I Drive Hub Propellers - Install thrust washer, propeller, continuity washer, thrust hub,

propeller nut retainer, and propeller nut onto the shaft.

Loading...

Loading...