D7.3L D-TRONIC DIESEL ENGINES - BRAVO MODELS

Page 25 of 90

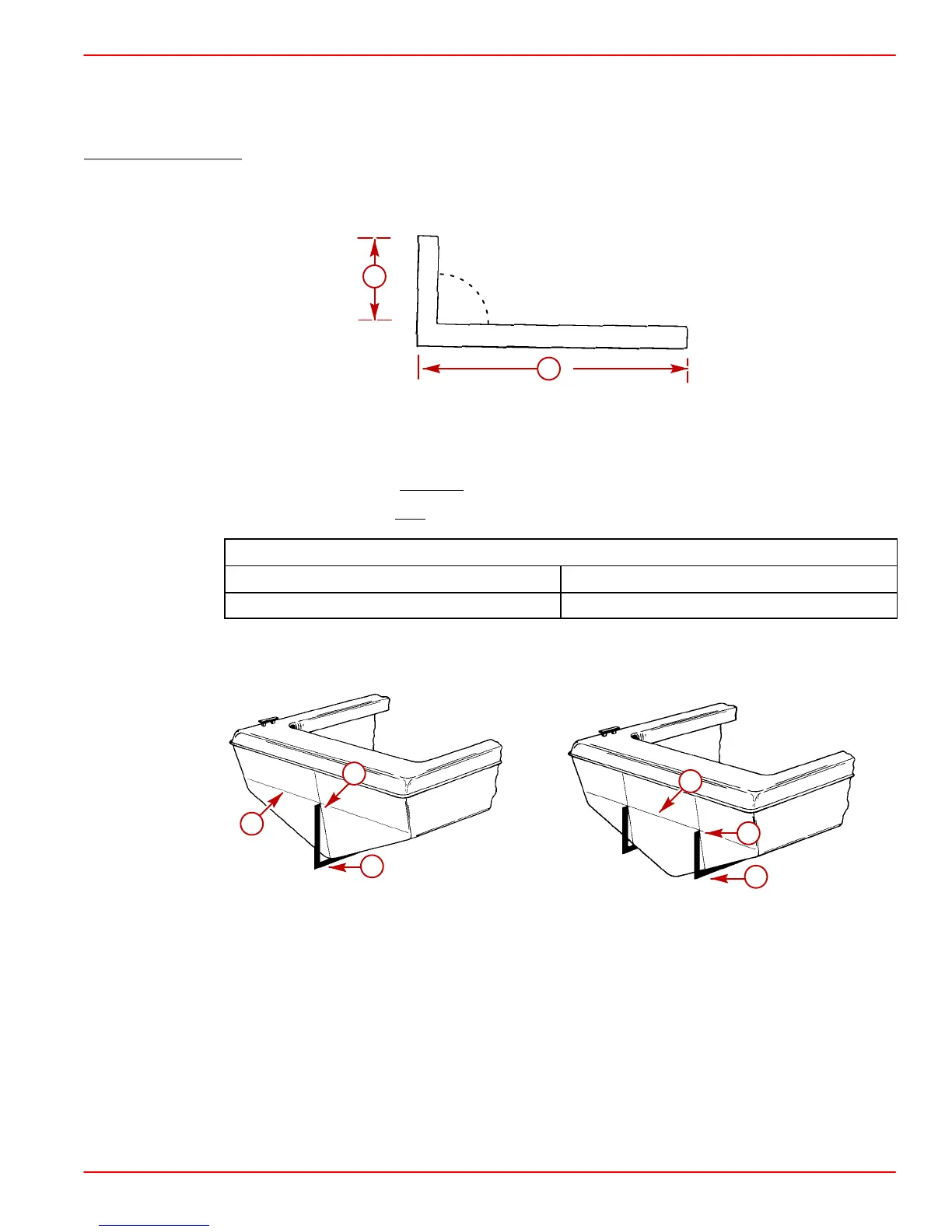

Finding Crankshaft Horizontal Centerline (“X” Dimension)

“X” Dimension can be measured by the “90° Tool Method” or by the “Tape Measure Method.”

90

° TOOL METHOD

1. Construct 90° tool.

71621

90°

b

a

a-Dimension from Chart Below

b-Measurement: 4 ft. (1.2 m)

To Lower Drive Unit - Subtract

from dimension “a”.

To Raise Drive Unit - Add

to dimension “a”.

90° TOOL VERTICAL DIMENSION CHART

Sterndrive Unit Location

Bravo One/Two/Three 13-9/16 in. (345mm)

IMPORTANT: This dimension should only be raised or lowered after proper testing.

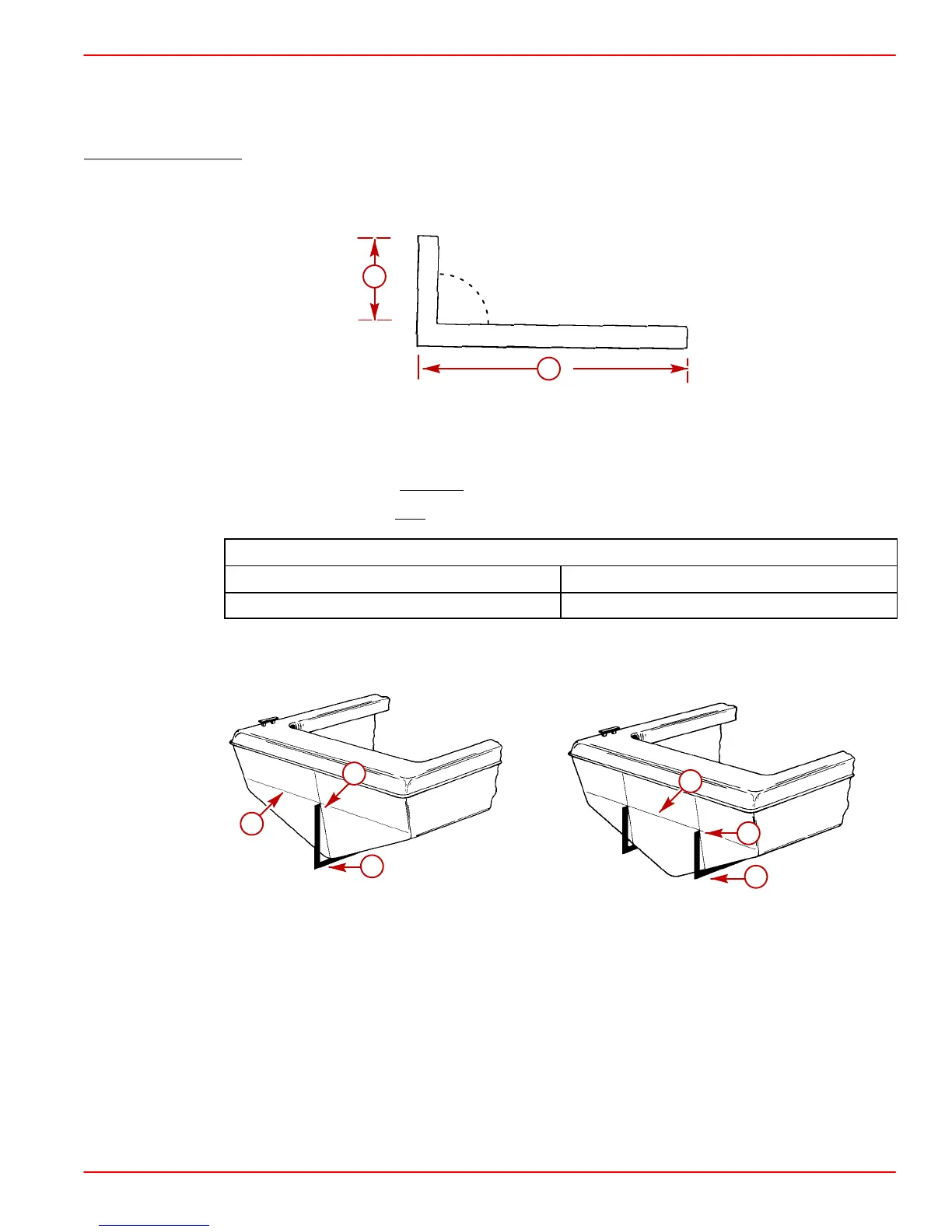

2. Determine “X” Dimension location of crankshaft centerline(s).

71622

71623

c

a

b

c

b

a

Single Engine Dual Engine

a-Place 90

° Tool Along Boat Bottom at Vertical Centerline

b-Point at Which Top of Tool Contacts Transom on Vertical Centerline is Crank-

shaft Horizontal Centerline.

c-Draw a Line Perpendicular to Vertical Centerline at Crankshaft Horizontal

Centerline.

Loading...

Loading...