INSTALLATION

Page 1D-36 90-888438 JUNE 2002

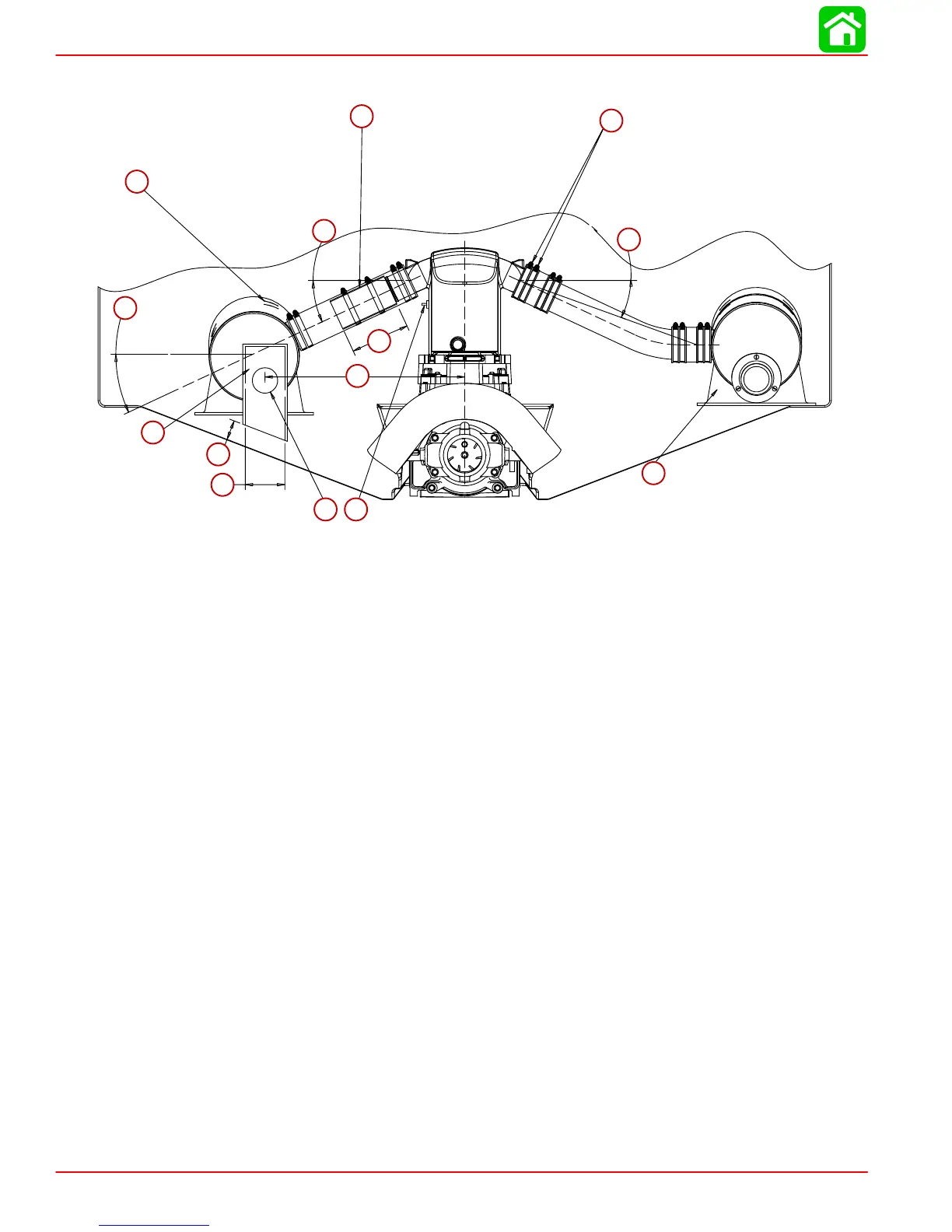

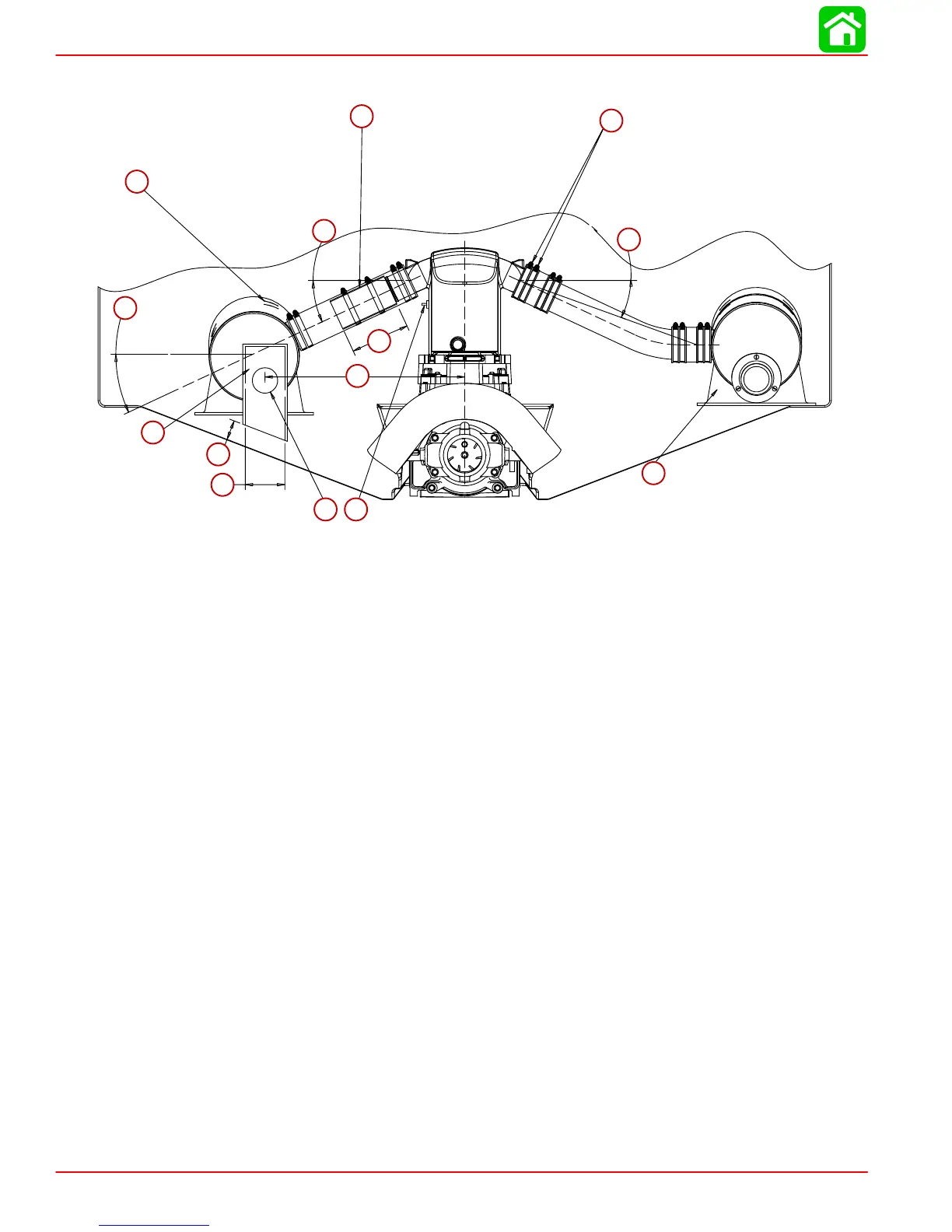

Aft View

a

b

c

d

e

f

g

h

i

j

k l

m

n

a-Alternate Installation – If rubber hosing is to be used for connection between

the expansion chamber and the muffler, a inner sleeve made of 6061–T6, 14

gauge aluminum tubing must be used as liner and secured with 2 stainless

steel hose clamps p/n 54–815504 or equivalent.

b-Typical Recommended Installation – 54–815504, 256 stainless steel clamp or

equivalent. All exhaust hoses and/or tubes must be secured with 2 clamps at

each connection.

c-Mufflers may be mounted using straight piping.

d-25° outlet angle of expansion chamber.

e-6.0 in (15.2 cm) minimum.

f-Reference maximum practical.

g-25° maximum from horizontal.

h-Optional exhaust outlet cover.

i-2.0 in (5.1 cm) minimum.

j-4.0 in (10.2 cm).

k-To minimize the backflow of exhaust gases into the cockpit or interior of boat,

the exhaust termination should be located as far outboard of the centerline as

practical.

l-Final system installation shall be reviewed by a MERCURY Field Representa-

tive using a modified expansion chamber to ensure back pressure does not ex-

ceed 1.8 psi (10.3 kg) at 1000 ft (304.8 m) above sea level or less. This test

needs to be performed with the boat in the water and under way. No special

loading of the boat is required. However, the engine must be capable of reach-

ing the specified W.O.T. engine speed. Maximum R.P.M. must be verified using

an accurate service tachometer.

m-Exhaust system components should be rubber mounted, independently sup-

ported and restrained to minimize noise transmission to the boat and stress on

exhaust system components.

n-10° minimum angle from expansion chamber outlet to muffler inlet.

Loading...

Loading...