68

a

b

c

d

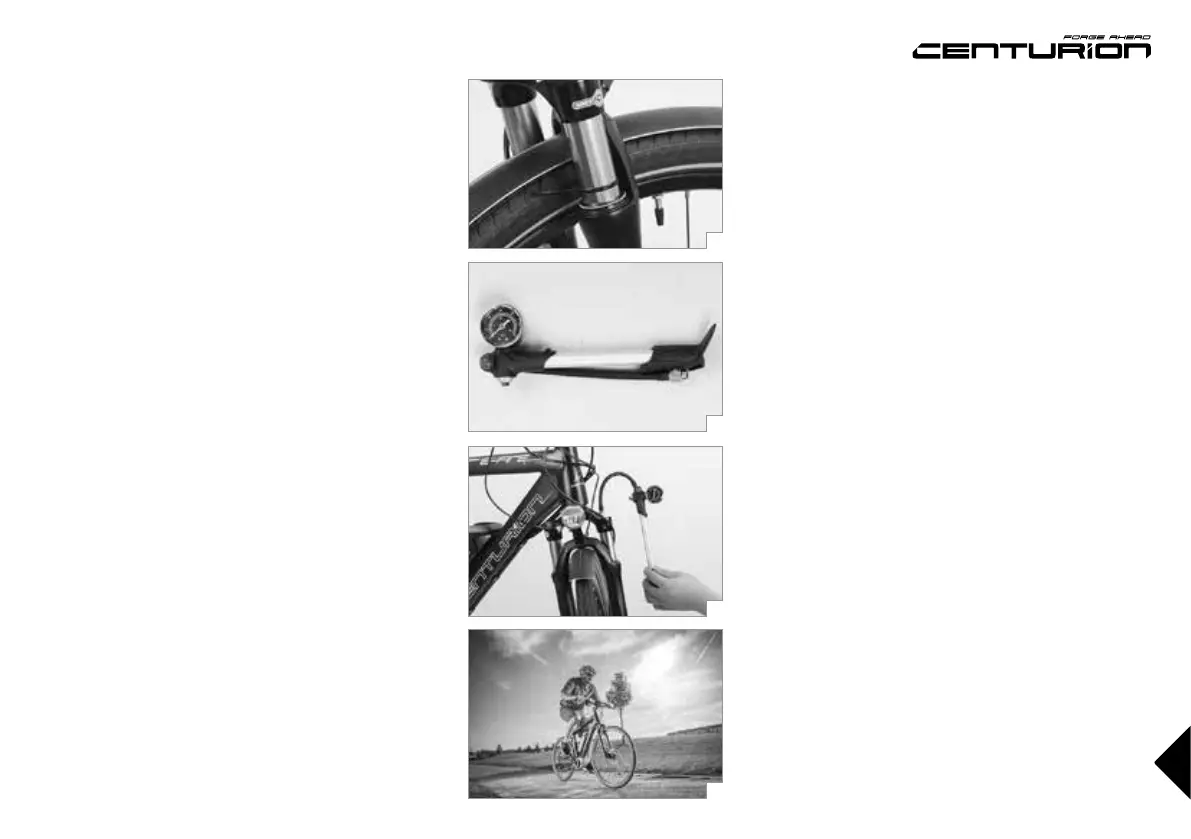

Put on your usual riding clothing (including if neces-

sary a packed rucksack), sit on your bike and bring

yourself into the usual riding position. Lean against a

fixed object (railings, wall etc.) and make sure you do

not fall over. Ask a helper to move the rubber ring or

the cable tie downwards against the dust seal at the

lower leg.

Get off your bike so that the fork does not compress

any more. The distance between the rubber ring/

cable tie and the wiper is the negative suspension

travel, or sag

(a)

. Compare it against the total sus-

pension travel (as specified by the manufacturer) to

determine whether the suspension should be set to

be harder or softer.

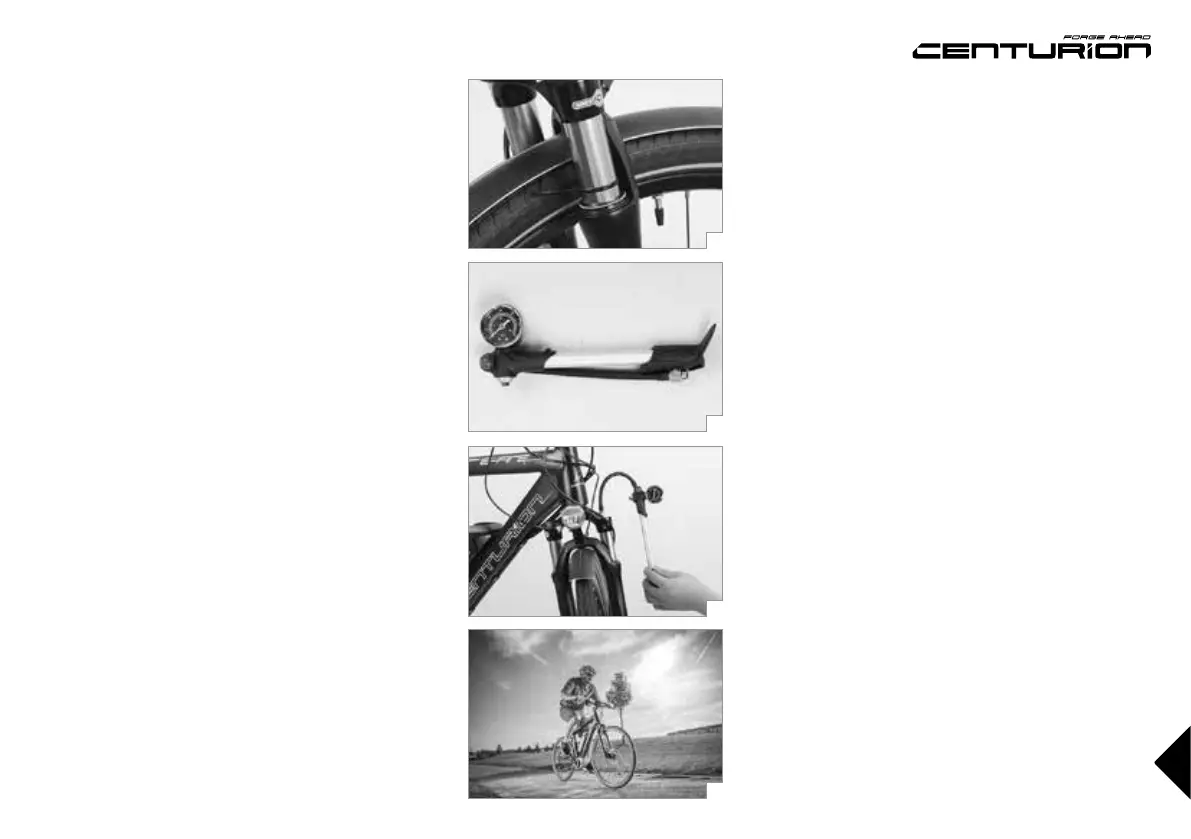

With pneumatic suspension forks the spring rate is

set by the air pressure in the fork. The pressure must

be set before the first ride by means of a special

high-pressure pump with pressure gauge

(b)

and

modified later as required due to changes in the

weight of the rider and/or load

(c)

.

Note the appropriate setting values and check them

subsequently at regular intervals. Always follow the

recommendations of the manufacturer and never

exceed the maximum air pressure for the suspension

fork. Always make a test ride after each change to

the settings.

In the case of most suspension forks with coil springs

a preload can be applied to the springs within tight

limits by turning a knob at the top of the fork crown.

If that is not possible and the desired negative sus-

pension travel (“sag”) cannot be set, the coil springs

must be replaced by harder or softer models. The

replacement is a job for the CENTURION dealer.

When replacing any parts, be sure to only use parts

that bear the appropriate mark and, to be on the safe

side, original spare parts. Your CENTURION dealer

will be pleased to help you.

Always make a test ride over terrain with various sur-

faces

(d)

after each change to the settings.

Check afterwards the position of the rubber ring/

cable tie. Its distance from the wiper is the maximum

suspension travel that you have used. If the rubber

ring/cable tie has moved by even a few millimeters,

the setting of the forks is too hard. Reduce the

pressure, or, in the case of coil springs, the spring

preload. If that brings no improvement, have the

springs replaced.

If the rubber ring/cable tie has shifted over the entire

length of the tube or if the fork audibly bottoms out

and hits the top repeatedly when riding off-road or

on bad roads, the setting of the springs is too soft.

In the case of air-suspension forks the pressure must

be increased. In the case of steel coils, have them

replaced by your CENTURION dealer.

Loading...

Loading...