19

Meritor Differential Carrier 17X

2 Maintenance

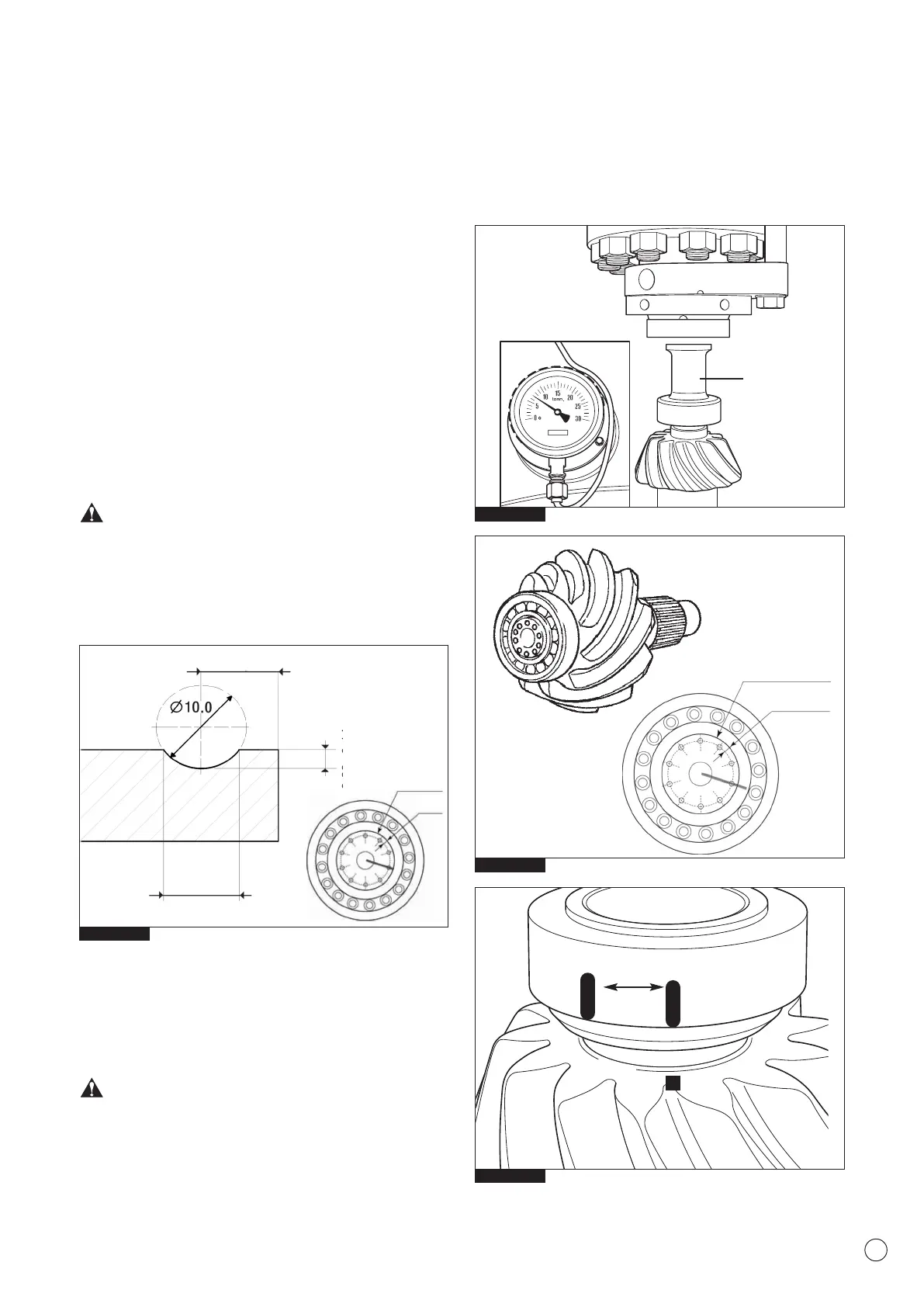

Fig. 2.11

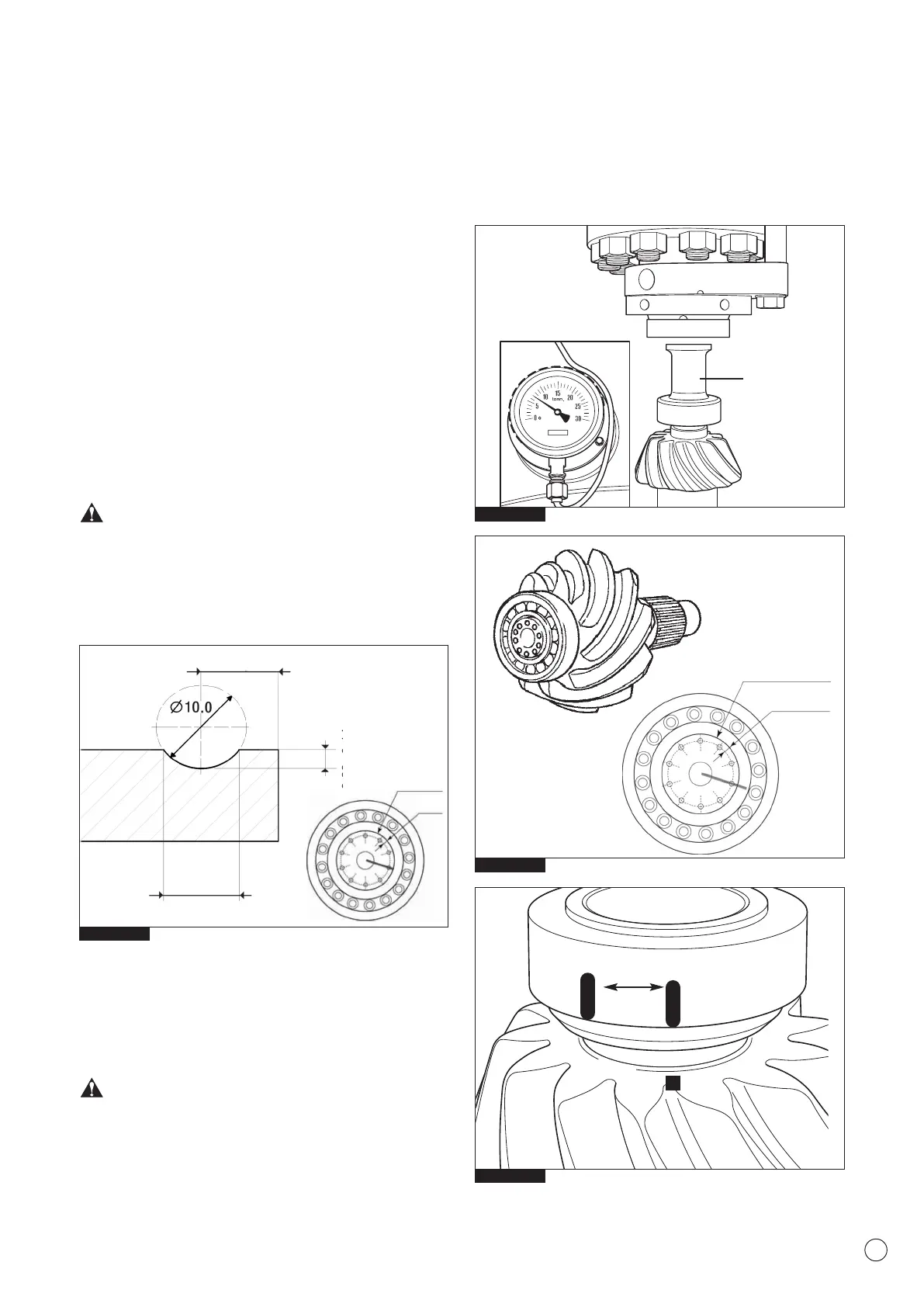

Fig. 2.12

Fig. 2.14

A press force of 6 - 8 tons is required (Fig.2.11).

3. Ball stake the pinion spigot in 10 places equally spaced

(Fig.2.12). The suitable service tool (CT05) has only five

staking balls present (Fig 2.13).

Mark the pinion to form a datum and the staking tool (CT06) in

two places at a 36 degree interval (Fig 2.14).

Align one of the marks on the staking tool with the datum mark

on the pinion.

Apply a load of 20 ton and form 5 staking points (4 tons per

staking point).

CAUTION:

The indentation diameter must be between 3.40 and 4.10

mm, corresponding to a depth of 0.30 to 0.44 mm under a

load of 4000 kg and a ball 10 mm in diameter.

Remove the tool and align the second mark on the tool with the

datum mark on the pinion. Again apply a load of 20 ton to

produce the second set of five staking points.

CAUTION:

When under cutting of the pinion nose is present it may be

necessary to adjust the position of the staking points to

ensure they avoid any undercut; in this case a minimum of

5 staking points are required.

36 Degrees

bevel pinion spigot

CT05

Fig. 2.13

bevel

pinion

spigot

Indentation

diameter:

3.40÷4.10

2.3

2.3

0.30÷0.44

CT06

2.3

Loading...

Loading...