IMO 11/19

IMO-553 EN 9

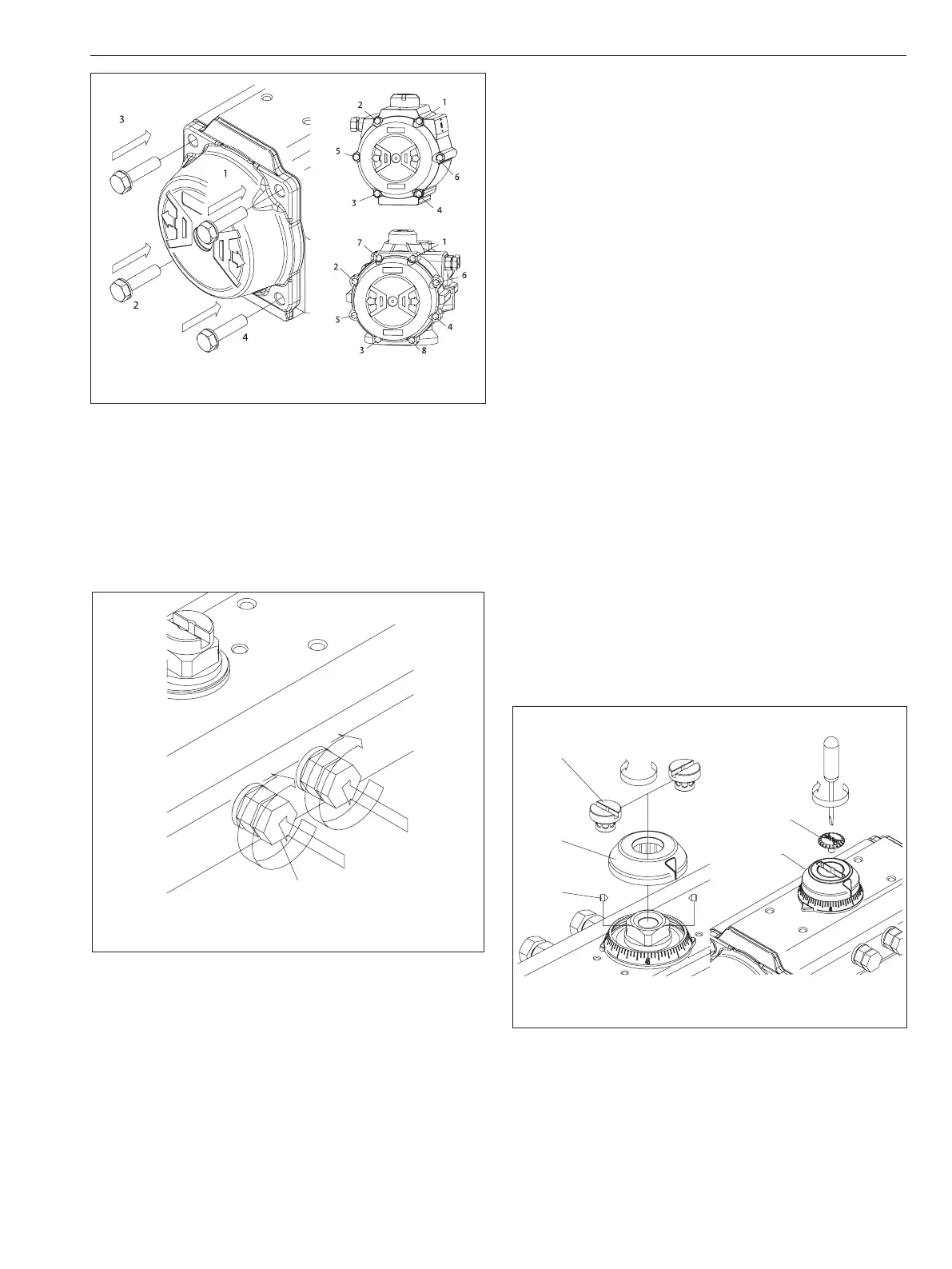

4. Assembly of Stop Screws (2) and Stroke

Adjustment. (Figure 17):

A. Insert the nut (4), washer (3), and o-ring (11) onto the

stop screws (2).

B. Screw the stop screws (2) into the body (50).

5. External Travel Stop Adjustment, (Figure 17):

2, 4, 3 and 11

Figure 17

The stop adjustment screw (2) to the right controls the

clockwise end of travel. The stop adjustment screw (2) to

the left controls the counter-clockwise end of travel.

A. Cycle the actuator/valve to the clockwise end of

travel and measure to determine if the valve is in

the proper position. (In most applications this will be

fully closed.)

B. If the valve is not in the correct clockwise position,

turn the right stop adjustment screw (2) IN to reduce

actuator travel, or OUT to increase actuator travel.

C. When the correct clockwise position is obtained, hold

the adjusting screw (2) stationary while tightening

the lock nut (4).

D. Cycle the actuator/valve to the counter-clockwise

end of travel and measure to determine if the valve is

in the proper position. (In most applications this will

be fully opened.)

E. If the valve is not in the correct counter-clockwise

position, turn the left stop adjustment screw (2)

IN to reduce actuator travel, or OUT to increase

actuator travel.

F. When the correct counter-clockwise position is

obtained, hold the adjusting screw (2) stationary

while tightening the lock nut (4).

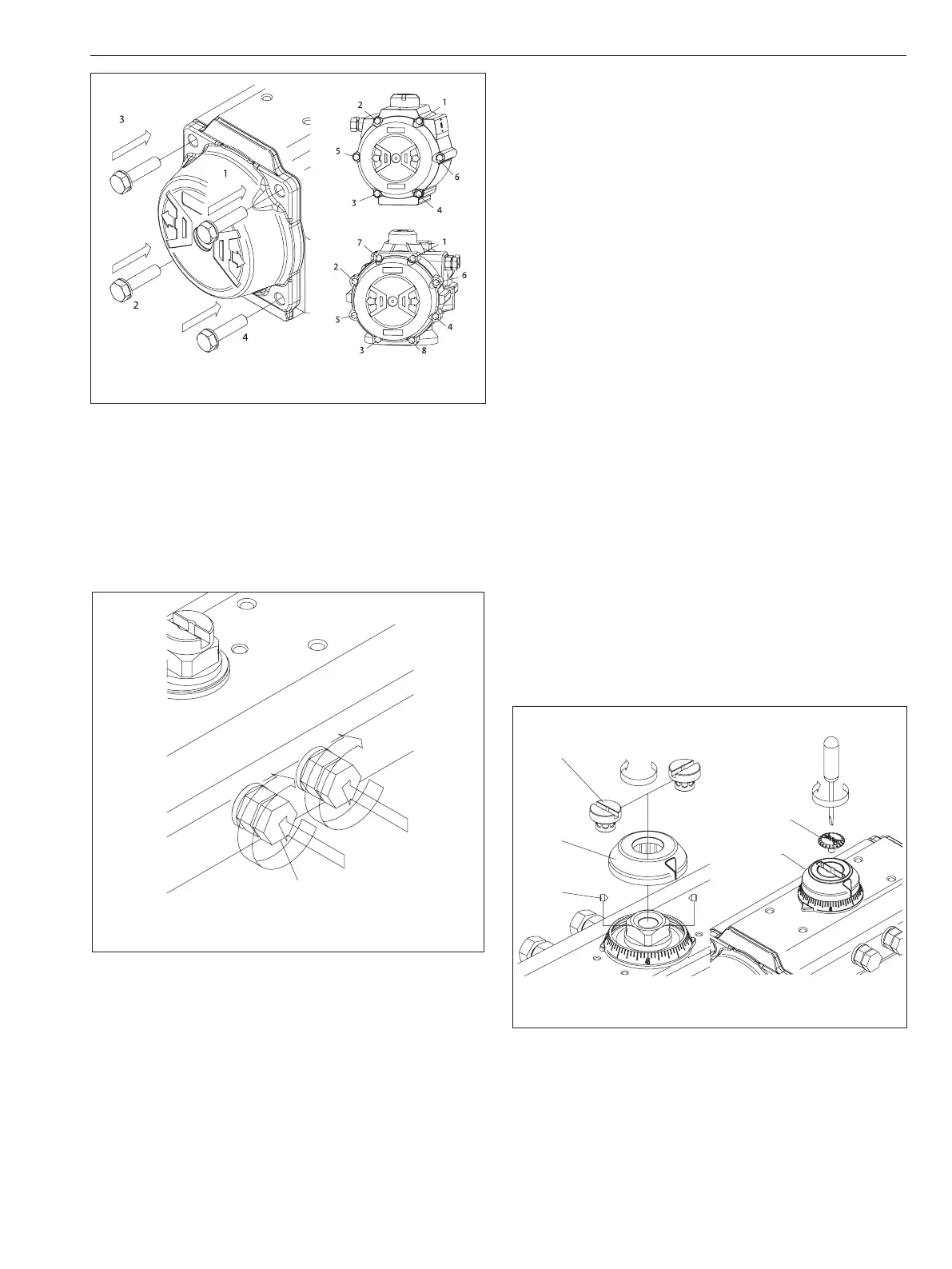

6. Position Indicator (19, 39) Assembly. (Figure 18):

A. Fit position indicator (19) on the shaft (60), verifying

that it indicates the correct actuator position.

B. Tighten cap screw (39) to secure the position

indicator.

7. Setting 100% Adjustable Stop (If applicable).

(Figure 19):

To limit the rotation on the stroke beyond the standard ±5°

of a VPVL actuator, a stainless steel 100% adjustable travel

stop option can be added. The stops, located in the end caps,

allow the valve position to be set anywhere between full

closed and full open. This option limits travel of only the

counter-clockwise stroke for standard double-acting and

spring-closed units. Follow the proceeding steps in order to

set the 100% adjustable travel stops.

19.5

19.1

19.6

19

39

Figure 18

Figure 16

Loading...

Loading...