83

APPENDIX B

The scrapping edge of the conveyor is subjected to wear when the conveyor transports the

solids towards the narrow drum end. The wear rate depends on the size and type of the

solids. The wear will reduce the transporting capacity and thus the separating results. A far

advanced wear i.e. radially .250 mm (6.4 mm) or more will also cause high repair costs. It is

necessary, therefore, to check the wear regular and observe how rapidly it progresses.

Normally the heaviest wear of the scraping edge occurs in the zone where the conical and

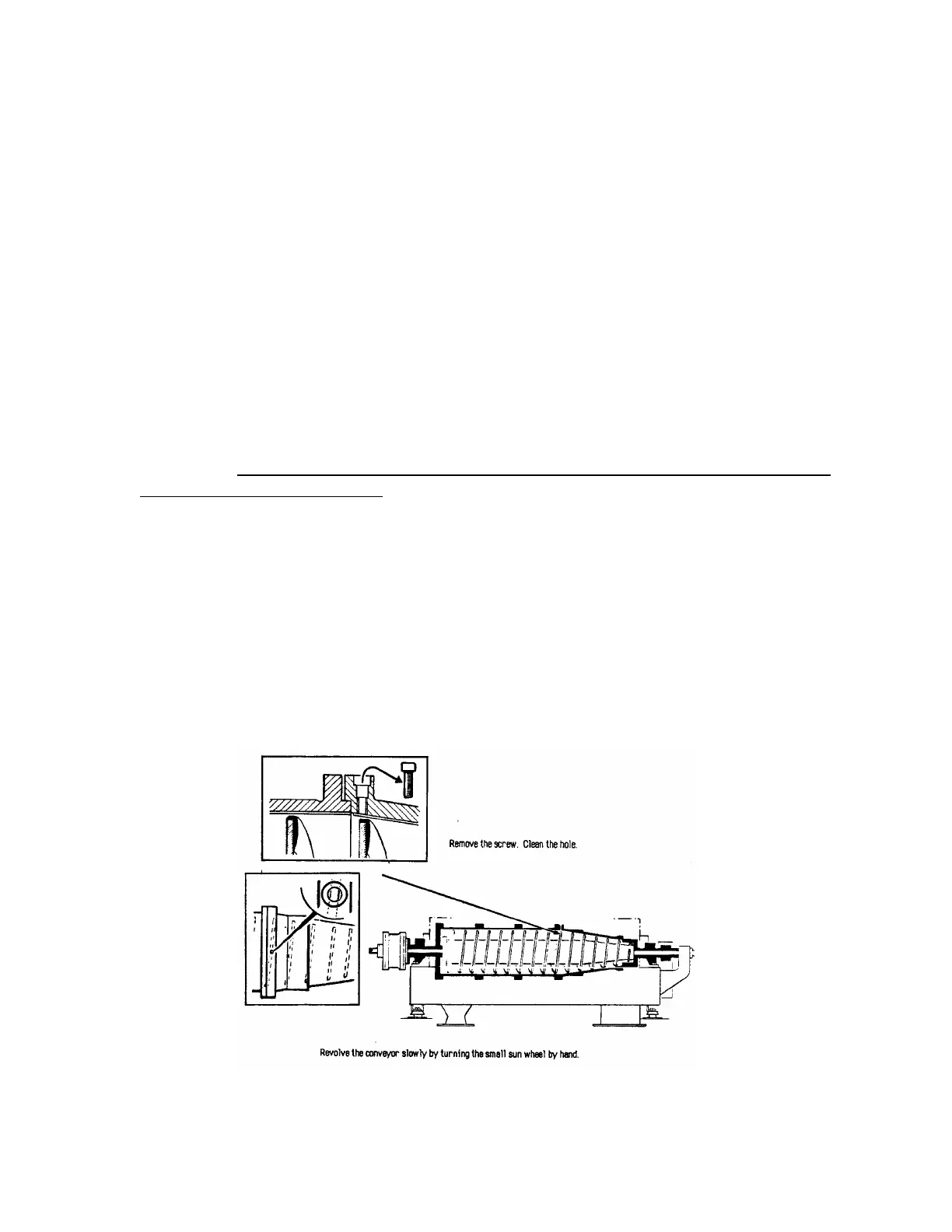

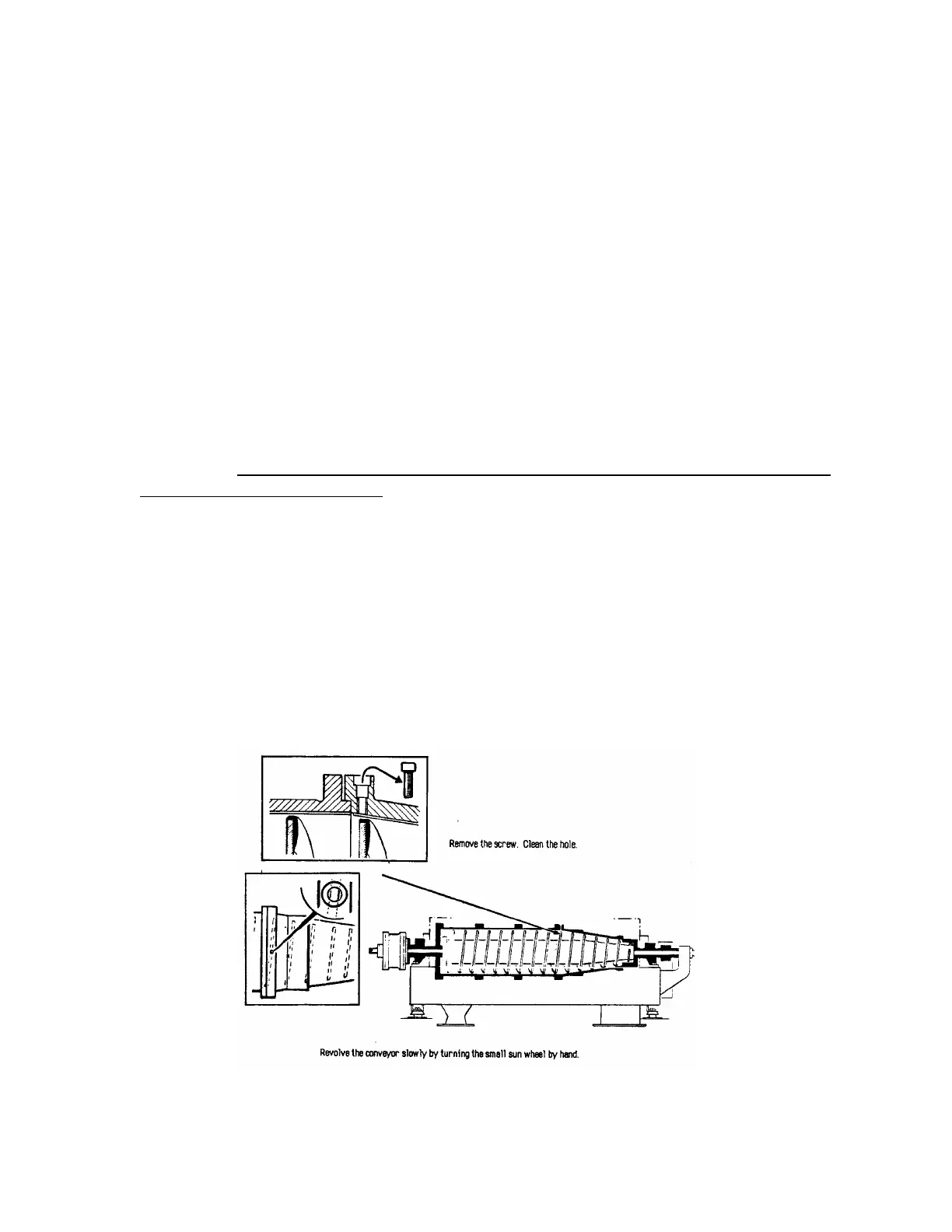

cylindrical parts of the drum meet. It is possible to measure the wear in this zone without

dismantling the drum. In the flange of the conical part of the jacket there is a hole (plugged

with a screw) through which the measuring can be done by means of a slide calipers. See

below.

The measurements should be recorded in a diagram, a number which is enclosed with this

description. Effect a first measuring (distance D - see below) before running a new machine

or a new conveyor the first time. Insert the numerical value in the square above the diagram.

Then measure the wear (i.e. the actual D - value reduced by the first measured D - value)

every 100th hour of operation. Plot the value in Diagram 1.

As a rule the wear rate can be established after 3-4 times. If the wear is heavy, i.e. .039 in (1

mm) or more after 400 hours of operation, continue the measurings every 100th hours of

operation and plot the values in Diagram 1. Otherwise extend the intervals to 500-1000

hours of operation and use Diagram 2.

Whenever a new or rebuilt conveyor is installed the above procedure should be followed.

(Extra diagrams are included and machine serial numbers should be marked on each diagram.

Loading...

Loading...