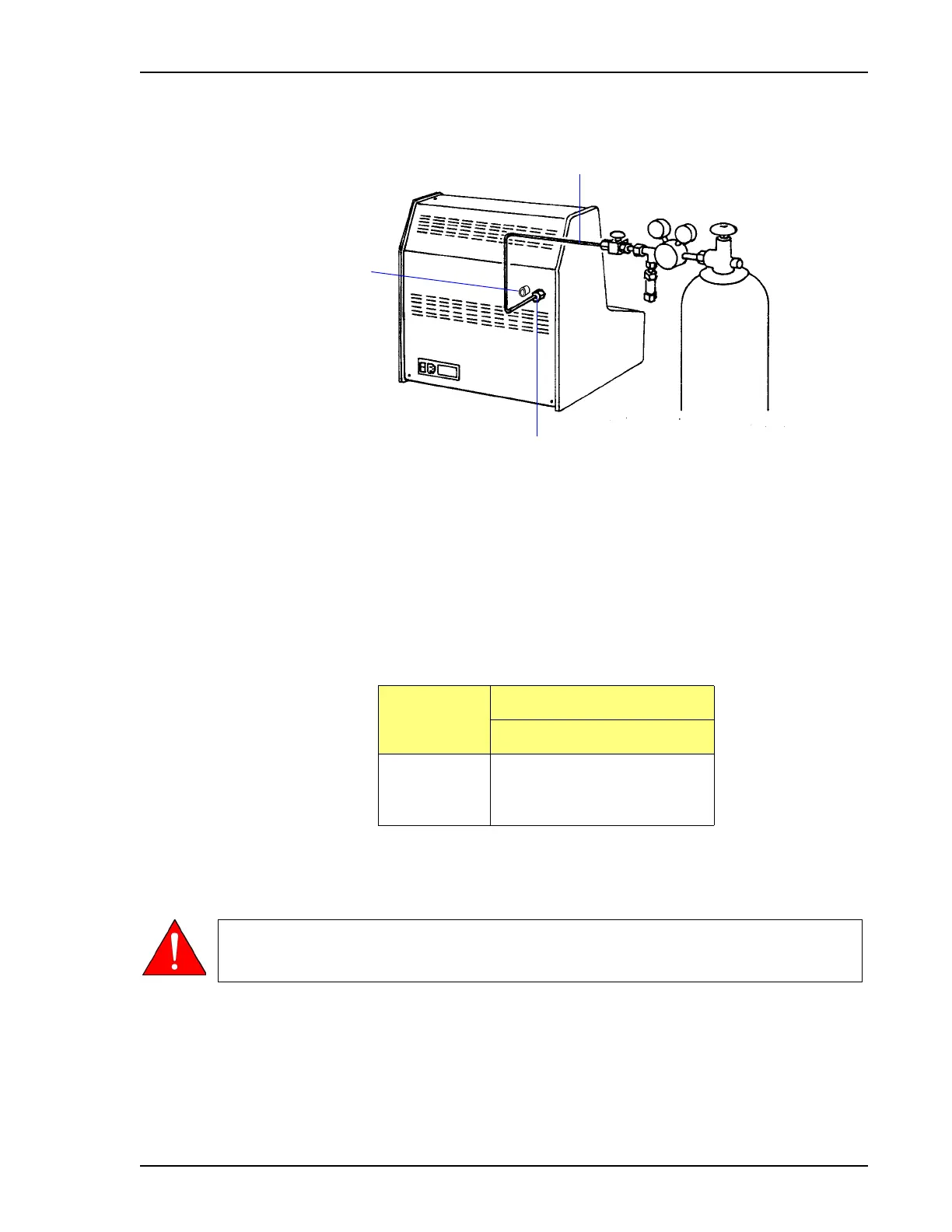

VacPrep 061 Rear Panel Connections

Feb 2013 1-9

6. Attach the other end of the copper tubing to the fitting on the back of the degasser.

7. Open the gas bottle shut-off valve.

8. Use the regulator pressure control knob to adjust the pressure. The following table shows

pressures and their resulting flow rates (tested with helium and nitrogen). If you do not

know the flow rate you want to use, start with about 10 cm

3

/min for flowing gas

preparation or for backfilling samples after vacuum preparation. Experience with your

samples will help you determine whether a change is required.

Table 1-2. Gas Flow Rate

A flow rate of 10-15 cm

3

/min is the maximum flow rate that would generally be used in

normal operation.

9. Close the gas bottle shut-off valve. Check the pressure. If it decreases, gas is probably

leaking at the fitting. Tighten the fitting. Then check the pressure again.

Flow Gauge Pressure

cm

3

/min psi kPa

10 3 21

15 5 35

Copper Tubing

Vacuum Port

Gas Fitting

Backfilling the sample tube increases its pressure to a level greater than atmospheric

pressure. If the gas pressure is greater than the recommended maximum of 5 psig (35

kPag), the sample tube could be ejected from the fitting or broken.

Loading...

Loading...