VacPrep 061 Sample Preparation

Feb 2013 2-15

Vacuum Preparation

The vacuum preparation method should be used only with materials which are not likely to

fluidize.

1. Turn all VAC/GAS control knobs to the OFF position. Ensure that the vacuum pump is

turned on and that gas is being supplied to the degasser.

2. Attach a vacuum fitting to each piece of flexible tubing at a degas station to be used for

sample preparation.

3. Place the degasser power switch in the ON ( | ) position.

4. Set the temperature controller by pressing (to increase) or (to decrease) the

temperature set point. The set point is the value displayed to the right of SV (Set Value) on

the lower line of the controller.

Some fine-powdered samples such as controlled pore glass, fluid-cracking catalysts,

and carbon may be difficult to prepare by vacuum preparation. Such materials tend to

fluidize and float up the sample tube toward the vacuum source. Micromeritics

recommends that such samples be first prepared by flowing gas preparation and, if

necessary, then be subjected to vacuum preparation.

If sample has been accidentally sucked into the instrument, follow the instructions for

cleaning and replacing vacuum fittings in Chapter 3.

When the VacPrep leaves the factory, stabilizing tubes are placed in heating stations 1

and 6 to prevent the heater block from shifting during shipment. Be sure to remove

these tubes before turning on the VacPrep.

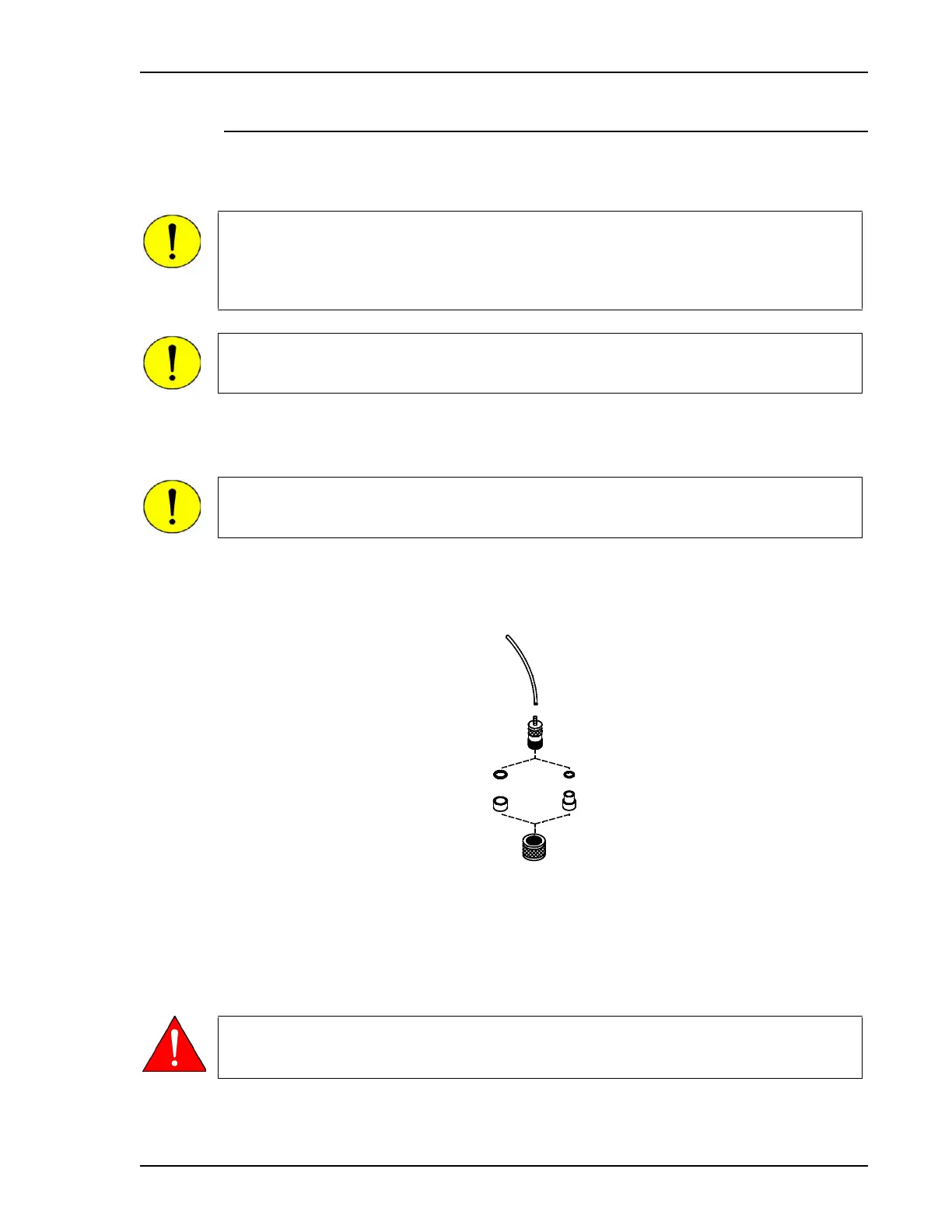

1/2-in. or 12mm

O-ring and ferrule

(for 1/2-in. or

12 mm sample

tubes)

3/8-in. or 9mm

O-ring and ferrule

(for 3/8-in. or 9mm

sample tubes)

Fitting

Nut

Heat is supplied to all six heating stations; to prevent burns, keep your hands away

from the interior of the heating stations.

Loading...

Loading...