20 Xpress Basics

Placing Discs on Spindles

As an automated disc production system, Xpress transports discs to

various processing stations internally. The operator’s only physical task

is to load blank discs for processing on the input spindle(s) and remove

finished discs from the output spindle(s).

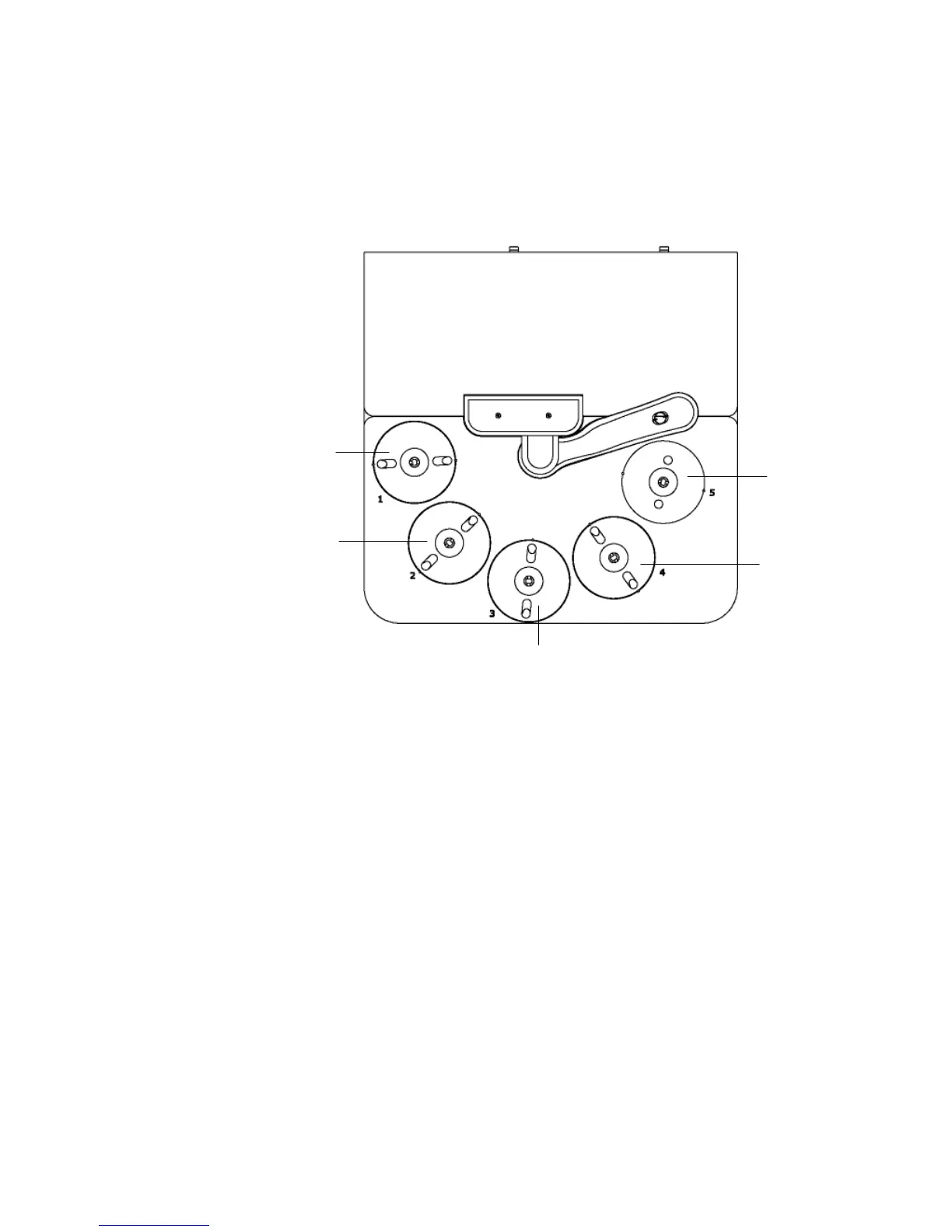

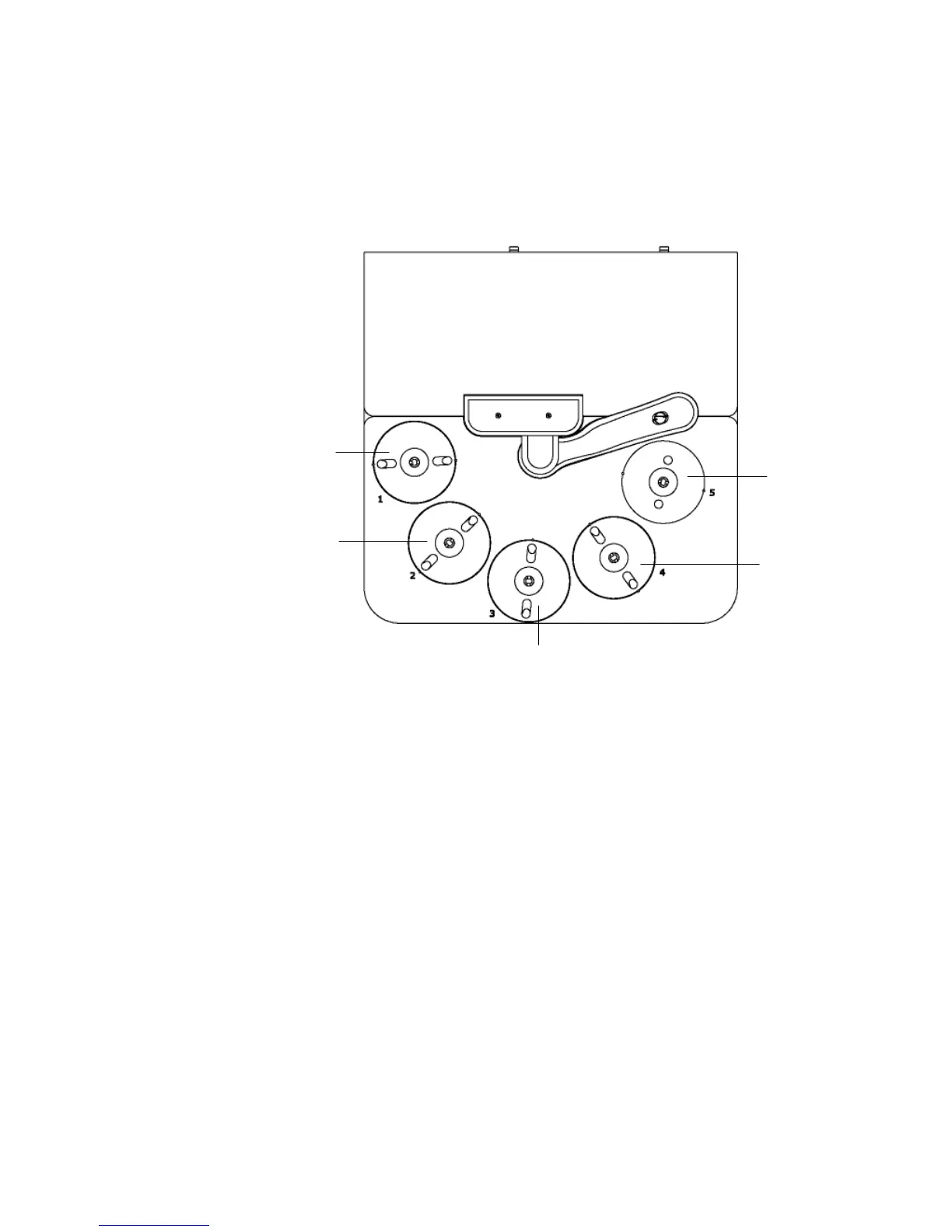

The diagram below shows the location and function of the various

spindles, viewed from above.

Each spindle holds 200 discs. To process a total of 600 discs with only 4

spindles, some spindles must be used to hold both blank and written

media (not at the same time). To start, blank media are loaded on

spindles 1, 2 and 3 and spindle 4 is left empty. Blank discs will be

retrieved from spindle 3 and completed discs will be placed on spindle 4.

When all discs have been removed from spindle 3, the whole operation

shifts by one spindle and blank discs will be retrieved from spindle 2 and

completed discs will be placed on (the now empty) spindle 3. When all

discs on spindle 2 have been used, the operation will shift one more time

and blank discs will be retrieved from spindle 1 and completed discs will

be placed on spindle 2. When all 600 discs have completed, there will be

discs on spindles 2, 3 and 4 and nothing on spindle 1.

When the disc production software is started, the production system

automatically resets itself to take discs from spindle 3 and places finished

discs on spindle 4. This is true even if the system was previously taking

discs from spindle 2 or spindle 1.

Whenever the disc production software is started, blank discs must be

loaded on spindles 3, 2 and 1 and spindle 4 must be empty.

Spindle #1

Tertiary Input Spindle (3

rd

200 discs)

Spindle #2

Secondary Input Spindle

(2

nd

200 discs)

Spindle #5

Reject Spindle

Spindle #4

Output Spindle

Spindle #3

Primary Input Spindle (1

st

200 discs)

Loading...

Loading...