MCAC-RTSM-2012-01 M-thermal Technical Manual (part 2)

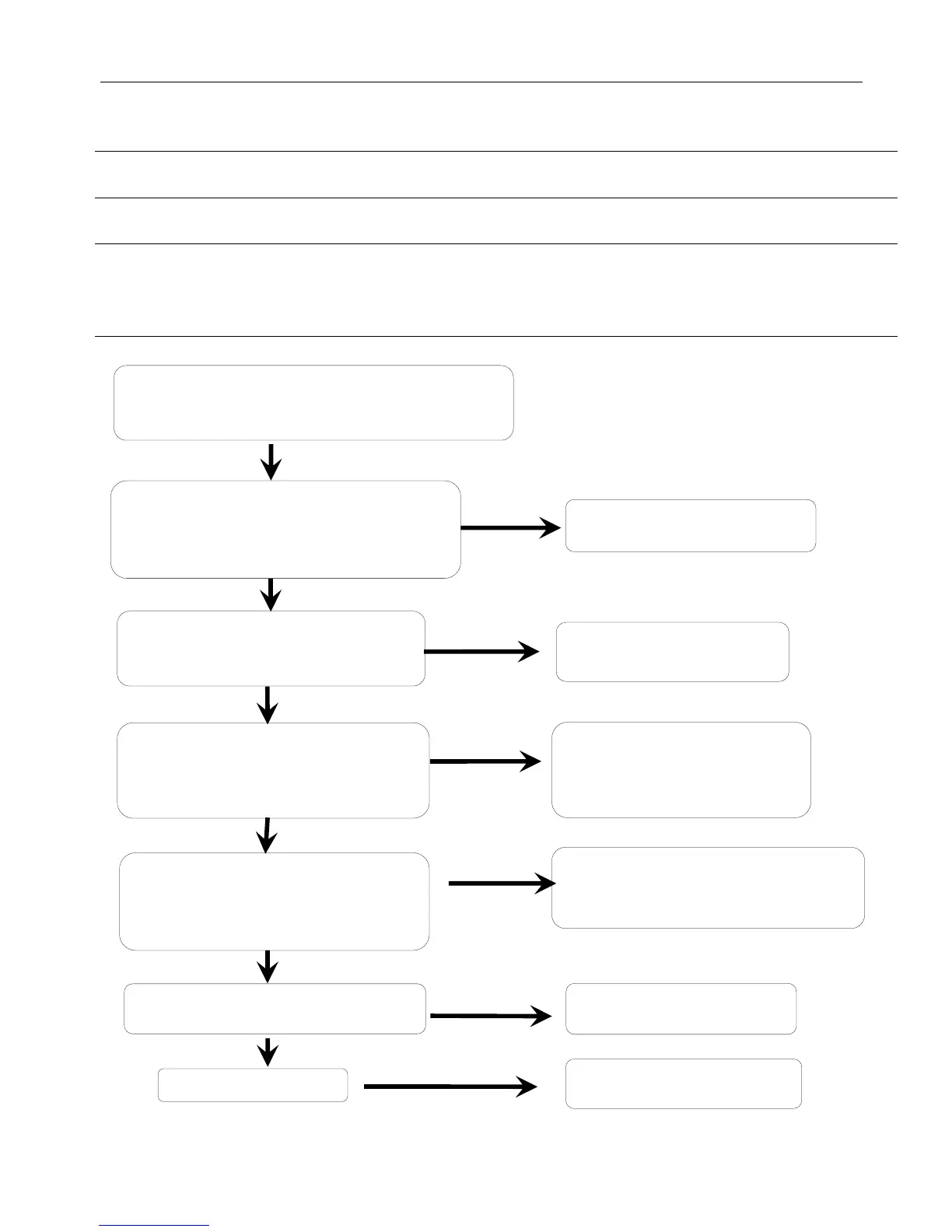

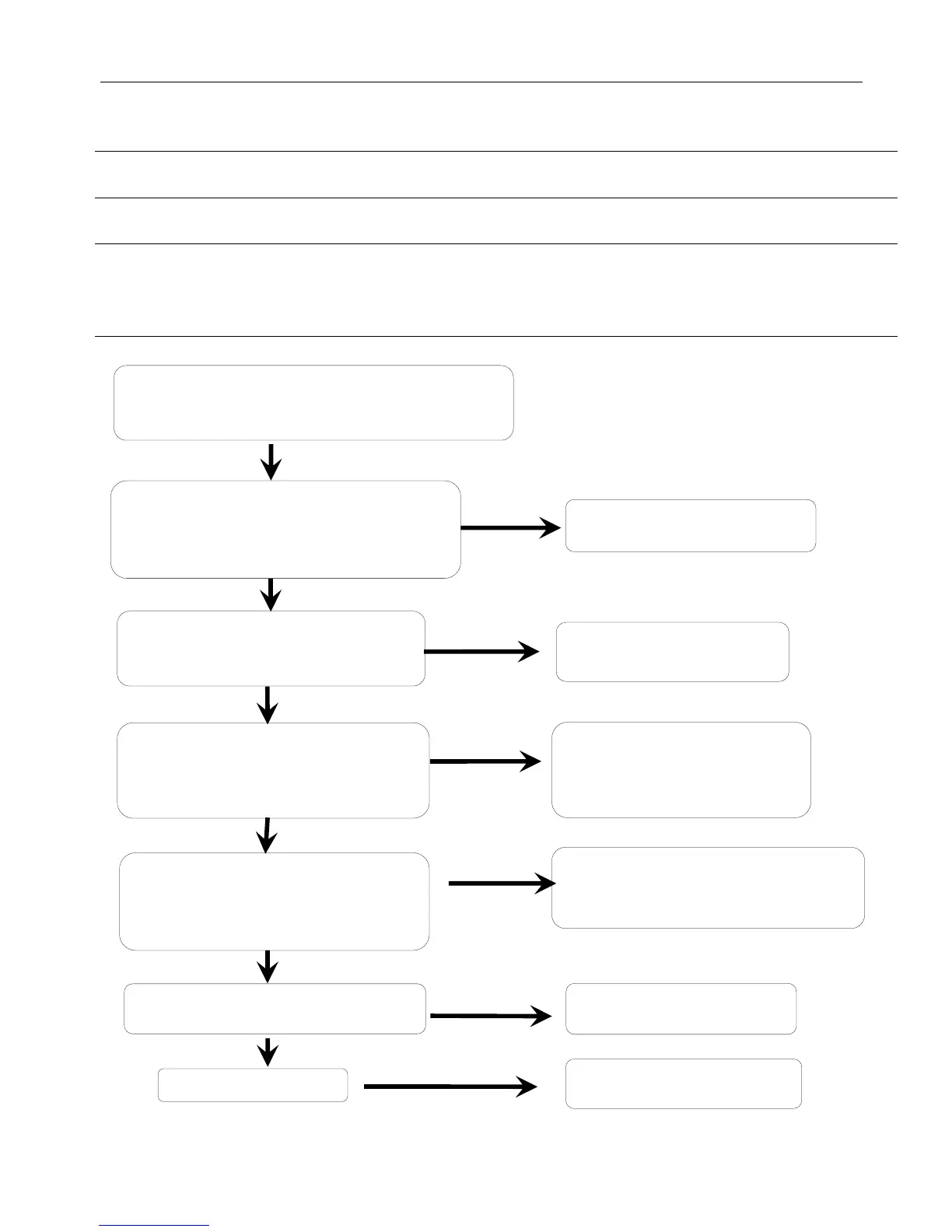

G. "P1": High pressure protection

The protection device circuit checks continuity in high pressure switch

1. Refrigerant is excess.

2. Refrigerant does not loop smoothly.

3. The refrigerant loop contains air.

4. Control board is defective.

P1: High pressure protection (R22 refrigerant system protects

at 3.3Mpa, recovers at 2.4MPa; R410 refrigerant system

protects at 4.4MPa, recovers at 3.2MPa).

Heat exchanging of ODU is not efficient. This may be

caused by dirty heat exchanger, abnormal ODU fan

running, air flow keeping off to the heat exchanger,

ODU are too near to each other.

System's liquid refrigerant loop is blocked.

This may be caused by blocked valve, pressed

tube, closed blocked valve.

Refrigerant is excess. In this circumstance, the

refrigerant's low pressure is high, so is the

high pressure side, while the discharge

System contains air or nitrogen. In this

circumstance, the high pressure is high, the

current is large, the discharge temperature is

high, compressor makes noise

Chip is defective or incorrectly installed. Or

the high pressure sensor is disconnected.

Control board is defective.

Check the system and fixed up

the error.

Check the system and get rid of the

block, and make the loop smooth.

Discharge part of the refrigerant.

Add some oil to the system if it

leaks during the discharge.

Discharge the refrigerant. Then vacuumize the

system and refill the refrigerant. Add oil to the

Reinstall the chip or replace it

with a fine one.

Replace the main control board.

Loading...

Loading...