Part

6

-

Diagnosis and Troubleshooting

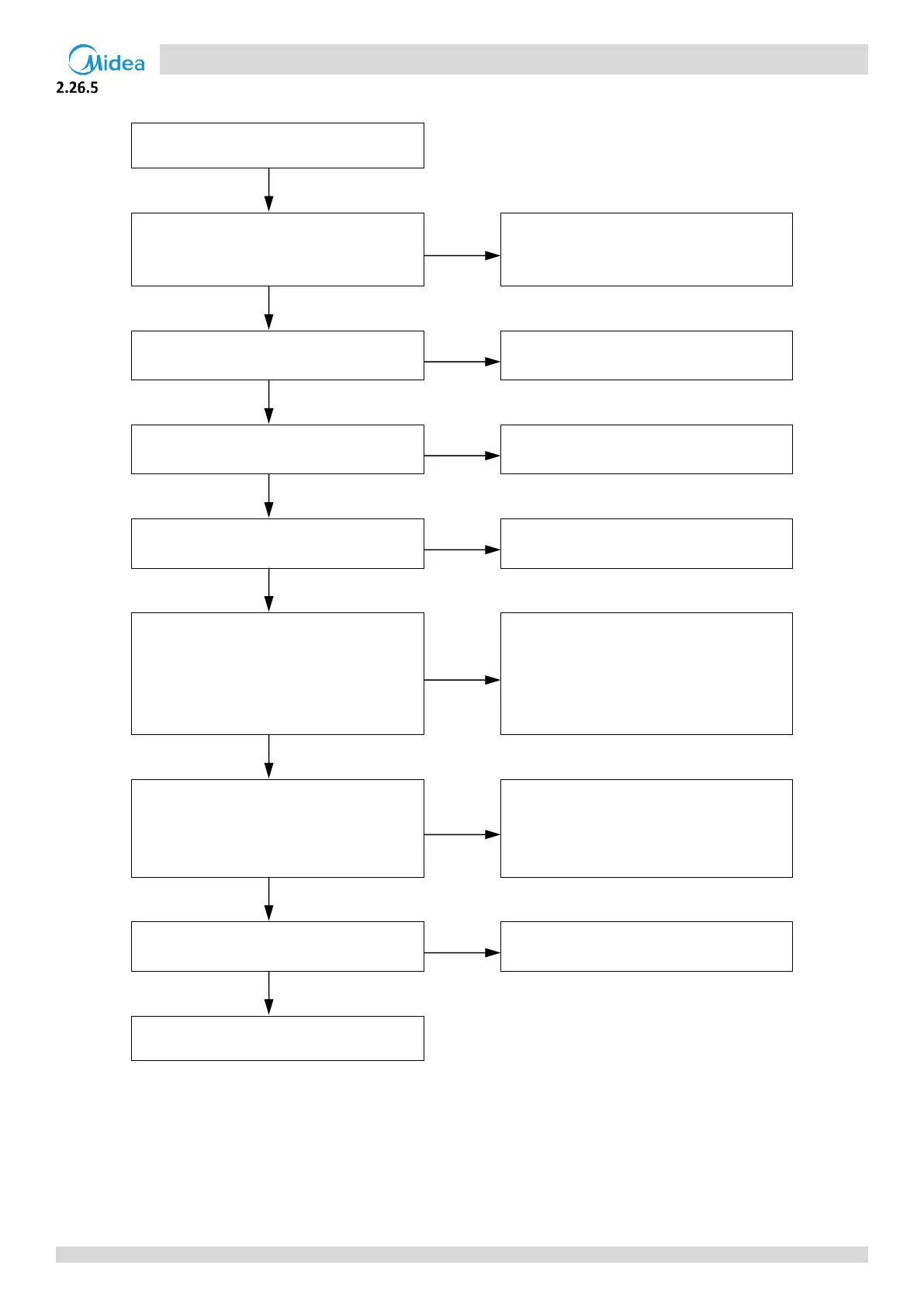

Compressor discharge pipe temperature

sensor does not be properly connected

to outdoor main PCB.

1

Ensure the sensor are connected

properly

Compressor discharge pipe temperature

sensor have short circuited or failed

2

Replace the faulty sensor

High pressure sensor connection on

outdoor main PCB is loose

3

Ensure the sensor is connected properly

High pressure sensor has short-circuited

or failed

4

Check the fault that EEVA in MS can not

be fully closed. Or check the fault that

expansion valve of IDU can not be fully

closed or the fan does not work, which

may result in partial evaporation.

T6B-T6A<3°C and T6A-Te <3°C and EEVC

minimum opening?

T8 -Te <2°C and EEVA minimum

opening(Evaporator)?

Check the fault that EEVA or EEVC can’t

be completely closed; or SV5 can’t be

opened.

Discharge part of the refrigerant. Add oil

if it leaks during discharge

Replace the outdoor main PCB

Notes:

1. Compressor top temperature sensor and discharge pipe temperature sensor connections are ports CN4 on the outdoor main PCB.

2. Measure sensor resistance. If the resistance is too low, the sensor has short-circuited. If the resistance is not consistent with the sensor’s resistance

characteristics table, the sensor has failed.

3. High pressure sensor connection is port CN17 on the outdoor main PCB.

4. Measure the resistance among the three terminals of the pressure sensor. If the resistance is of the order of mega Ohms or infinite, the pressure sensor has

failed.

5. Excess refrigerant causes discharge temperature to be lower than normal, discharge pressure to be higher than normal and suction pressure to be higher

than normal.

Loading...

Loading...