Part

6

-

Diagnosis and Troubleshooting

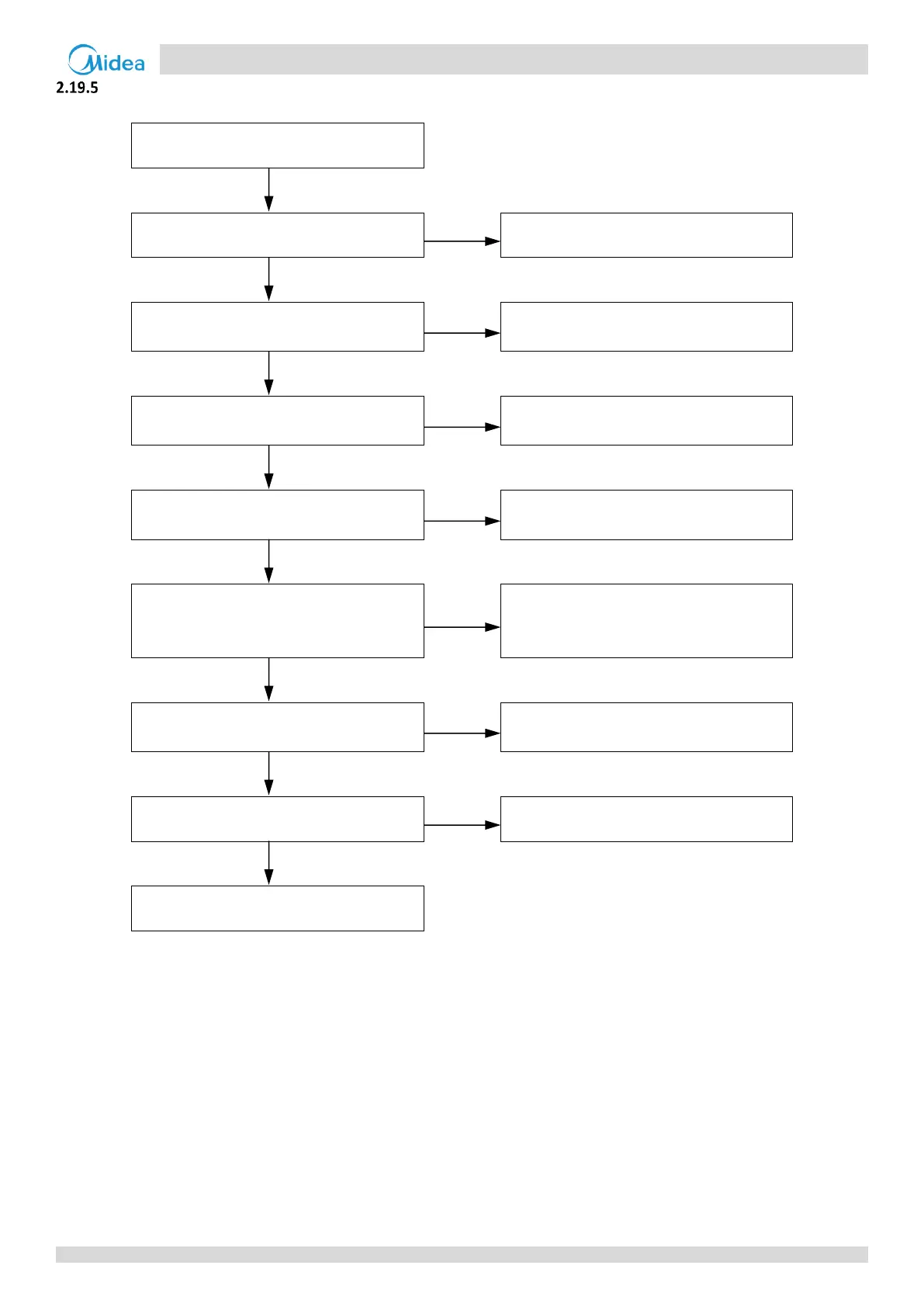

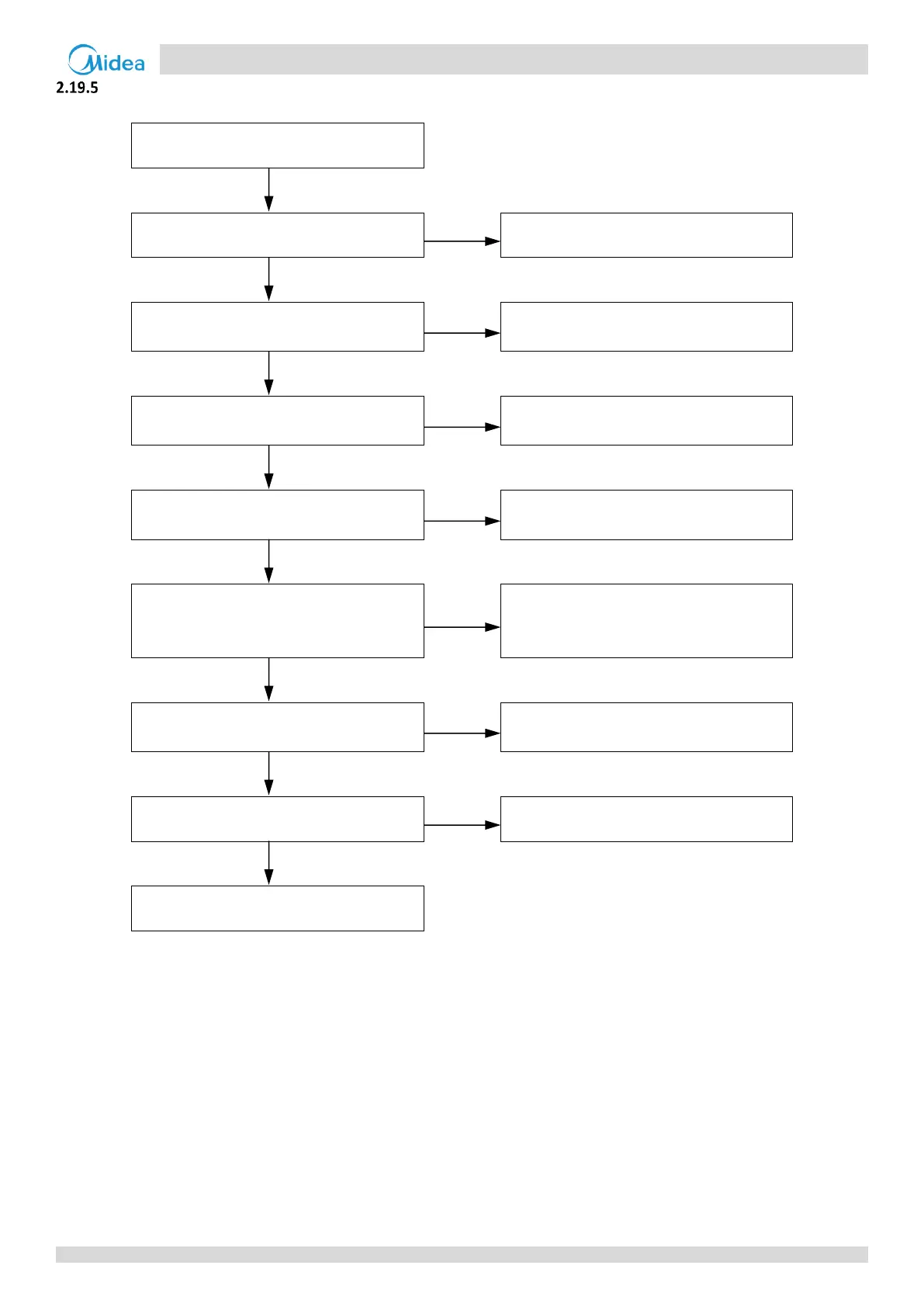

ODU stop valves are closed

High pressure sensor connection on

outdoor main PCB is loose

1

Ensure the sensor is connected properly

High pressure sensor has short-circuited

or failed

2

Discharge part of the refrigerant. Add oil

if it leaks during discharge

System contains air or nitrogen

4

Flush all refrigerant then vacuum the

system and recharge the refrigerant. Add

oil to the system if it leaks

The high pressure side is blocked, caused

by crushed or bent pipe or blocked EEV

5

Inspect the system and fix the error

The condenser heat exchange is poor

6

Inspect the system and fix the error

Replace the outdoor main PCB

Notes:

1. The high pressure sensor connection is port CN17 on the outdoor main PCB.

2. Measure the resistance among the three terminals of the pressure sensor. If the resistance is of the order of mega Ohms or infinite, the pressure sensor has

failed.

3. Excess refrigerant causes discharge temperature to be lower than normal, discharge pressure to be higher than normal and suction pressure to be higher

than normal.

4. Air or nitrogen in the system causes discharge temperature to be higher than normal, discharge pressure to be higher than normal, compressor current to

be higher than normal, abnormal compressor noise and an unsteady pressure meter reading.

5. High pressure side blockage causes discharge temperature to be higher than normal, discharge pressure to be higher than normal and suction pressure to

be lower than normal.

6. In cooling mode check outdoor heat exchangers, fans and air outlets for dirt/blockages. In heating mode check indoor heat exchangers, fans and air outlets

for dirt/blockages.

Loading...

Loading...