Electronics

Depending on the soldering process

used and the application the products

are to be used for soldering frames

used in the production of electronic

components and printed circuit boards

can be cleaned in this machine.

Printed circuit boards

Resin or colophonium coated circuit

boards can be cleaned in this machine.

The results will be influenced by the

type of fluxing agent used. Please seek

the advice of your application specialist

if required. A tenside additive is

required for cleaning (0.5 - 0.7 % at

65 - 75 °C, process 1 or 2, see

"Description of the machine - Water

recovery") or a special cleaning agent

(20% at 50 °C, process 3, see

"Description of the machine - Water

recovery"). If the rinse water or the

special cleaning agent is to be re-used

a buffer or recycling tank is required.

Fully demineralised water is required

for the rinse.

Fluxing agents and soldering paste

Residues from the soldering process

are water soluble and must be

removed. The cleaning process then

takes place in water only.

Batch times for cleaning are approx.

30 - 40 min, and approx. 30 - 50 min for

drying, depending on the complexity

and quantity of items being processed.

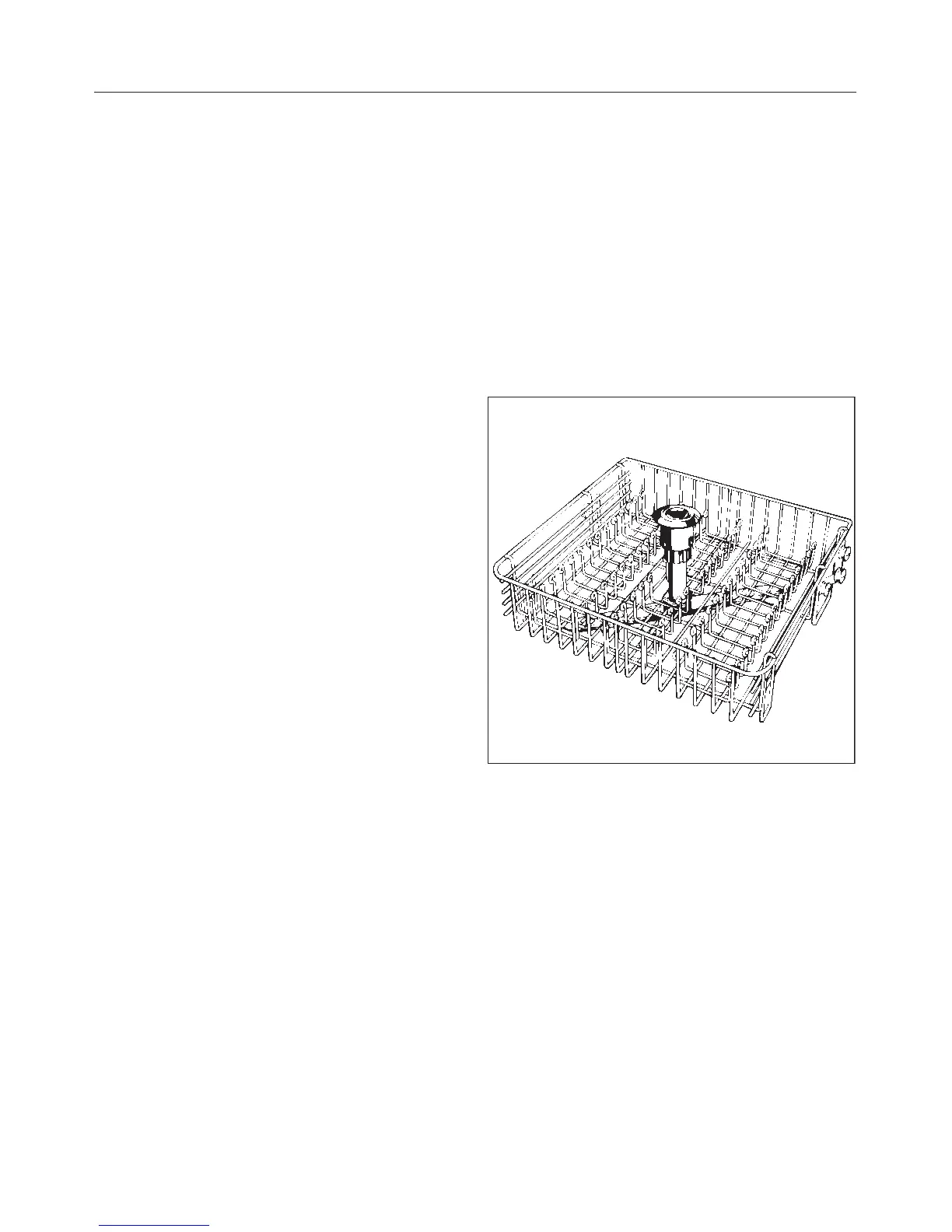

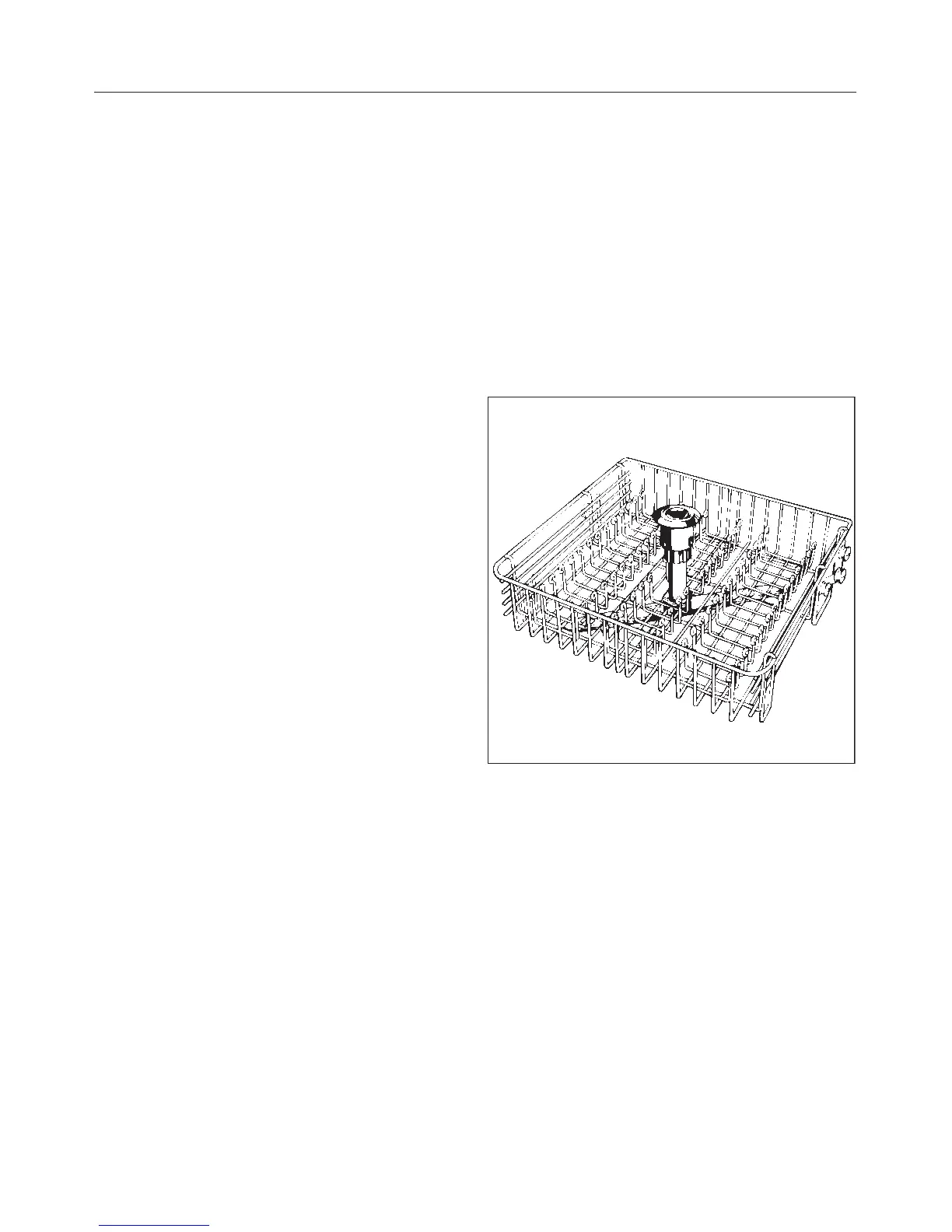

The special baskets for circuit boards,

upper basket O 500 and bottom basket

U 500 are made from plastic coated

stainless steel. Each is designed to

process 73 europa size circuit boards

per batch.

Upper basket O 500

Areas of application

24

Loading...

Loading...