10

Pulse time

The pulse time reflects the time the machine is

welding with the pulse current. The pulse current in

the pulse frequency is the set welding current. Time

is given in seconds.

Pause time

The pause time reflects the time the machine

is welding with base (background) current. Time is

given in seconds.

Base amp

Base (background) current is set as a percentage

value between 1 and 100% of the current level set on

the display (that is, pulse current), though it cannot be

less than 5 Amps.

Note 1: If the pulse function is used during AC-welding the

pulse times can be reduced in proportion to the

AC frequency as the pulse frequency must be 5

times higher than the AC frequency. If the pulse

times are to short the indicator for AC frequency

will flash on and off for 5 seconds.

I

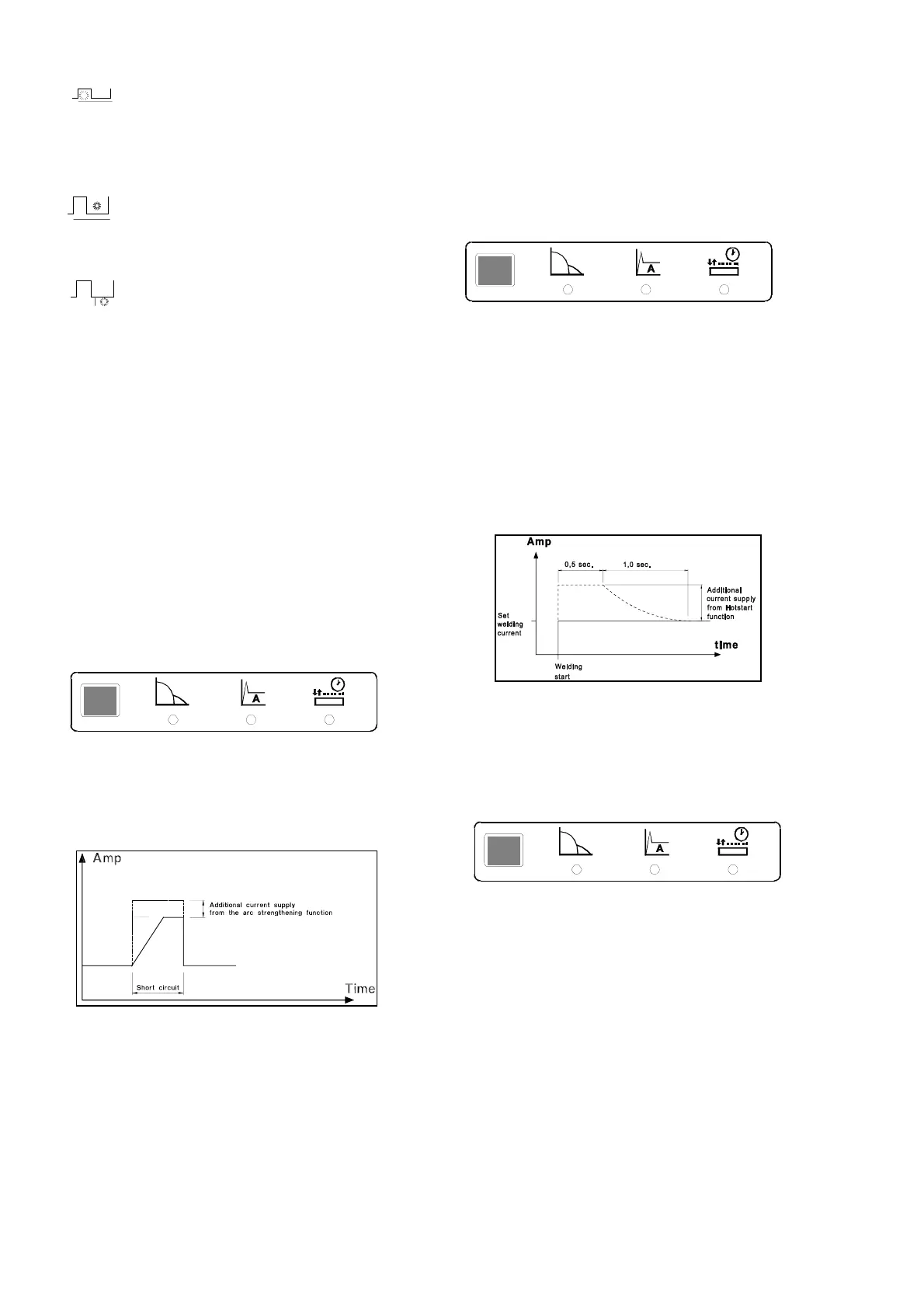

Arc power Used on the MMA welding process only,

the arc power function is used to

stabilise the arc.

I1

Arc power

This can be achieved by increasing welding current by

a percentage value when metal droplets are short-

circuited.

The additional current ceases when the short circuit

is no longer present.

The arc power value is a percentage value, and can

be set between 0 and 150% of the welding current

setting.

E.g. if the welding current is set to 40 A and Arc

power to 100% the additional current is 40 A equals

80 A when doing Arc power. If the Arc power is set to

150% the additional current is 60 A equals 100 A

when doing Arc power.

I2

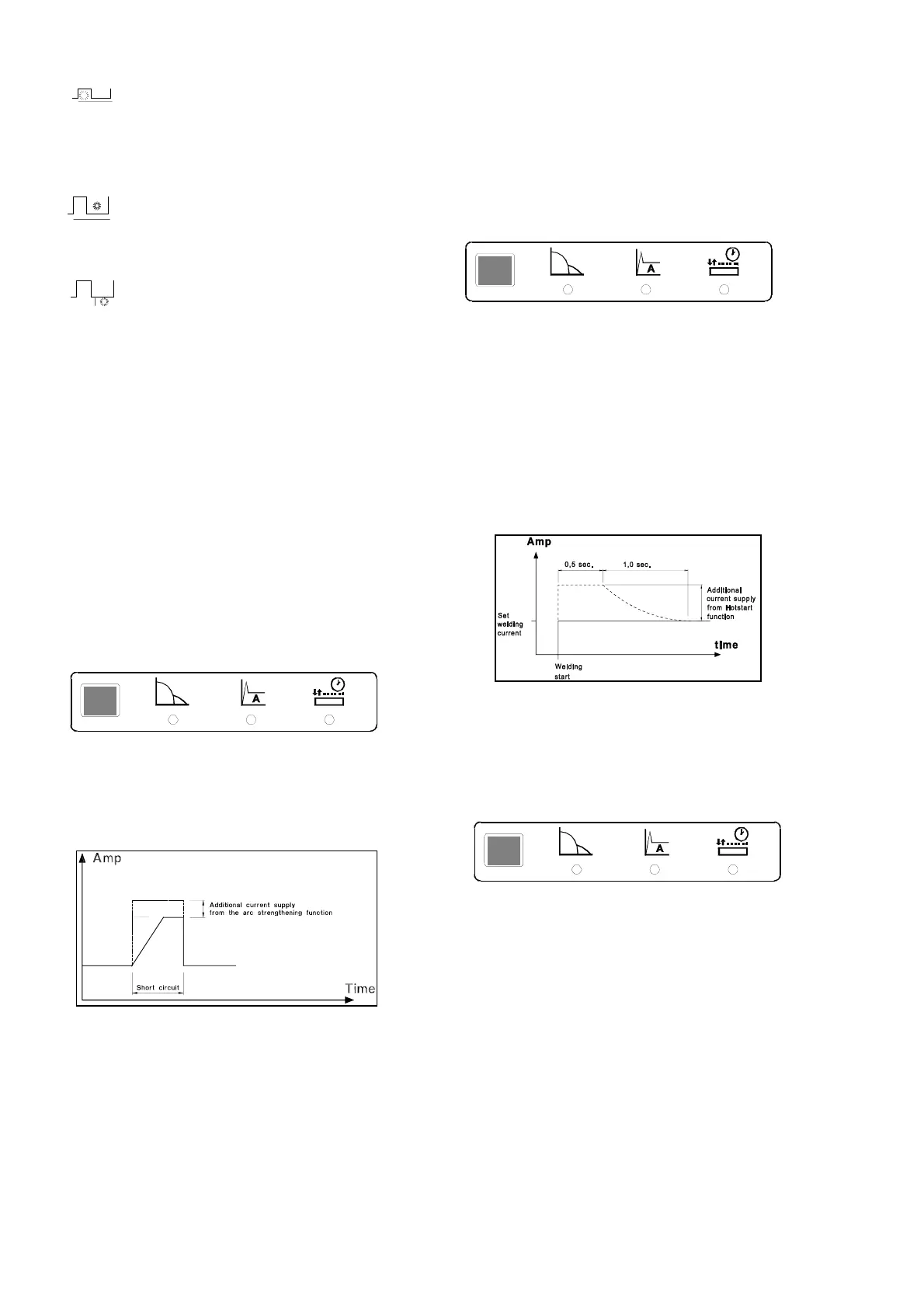

Hot start

Hot start Hot start is a function that helps to

establish the arc during MMA welding.

This can be achieved by increasing welding current

(when the electrode is applied to the workpiece) by a

certain percentage value in relation to the set value.

This increased start amp is maintained for half a

second, after which it decreases exponentially over a

period of one second to the set value of welding

current.

The hot start value reflects the percentage value by

which initial current is increased, and can be set

between 0% and 100%.

I3

Spot time

Spot time Spot time is the time for the production of

a spot-weld and can only be used with

the TIG process. Variable from 0-50.0

secs, the time includes any slope-up and

slope-down times and can be set only

after spot trigger mode has been

selected on the TRIG keypad.

Loading...

Loading...