11

J

AC-welding

This panel is divided into two sections, with the

function current type at the top, and the setting of

conditions for special AC-functions at the bottom.

Current type

It is possible to select either AC (alternating current)

or DC (direct current). In the TIG-welding process, AC

is used for the welding of aluminium and its alloys,

while DC is used for the welding of other materials.

When TIG welding aluminium or its alloys the positive

part of the AC-wave removes the oxide film covering

the surface of the workpiece, and the negative part of

the wave melts the material.

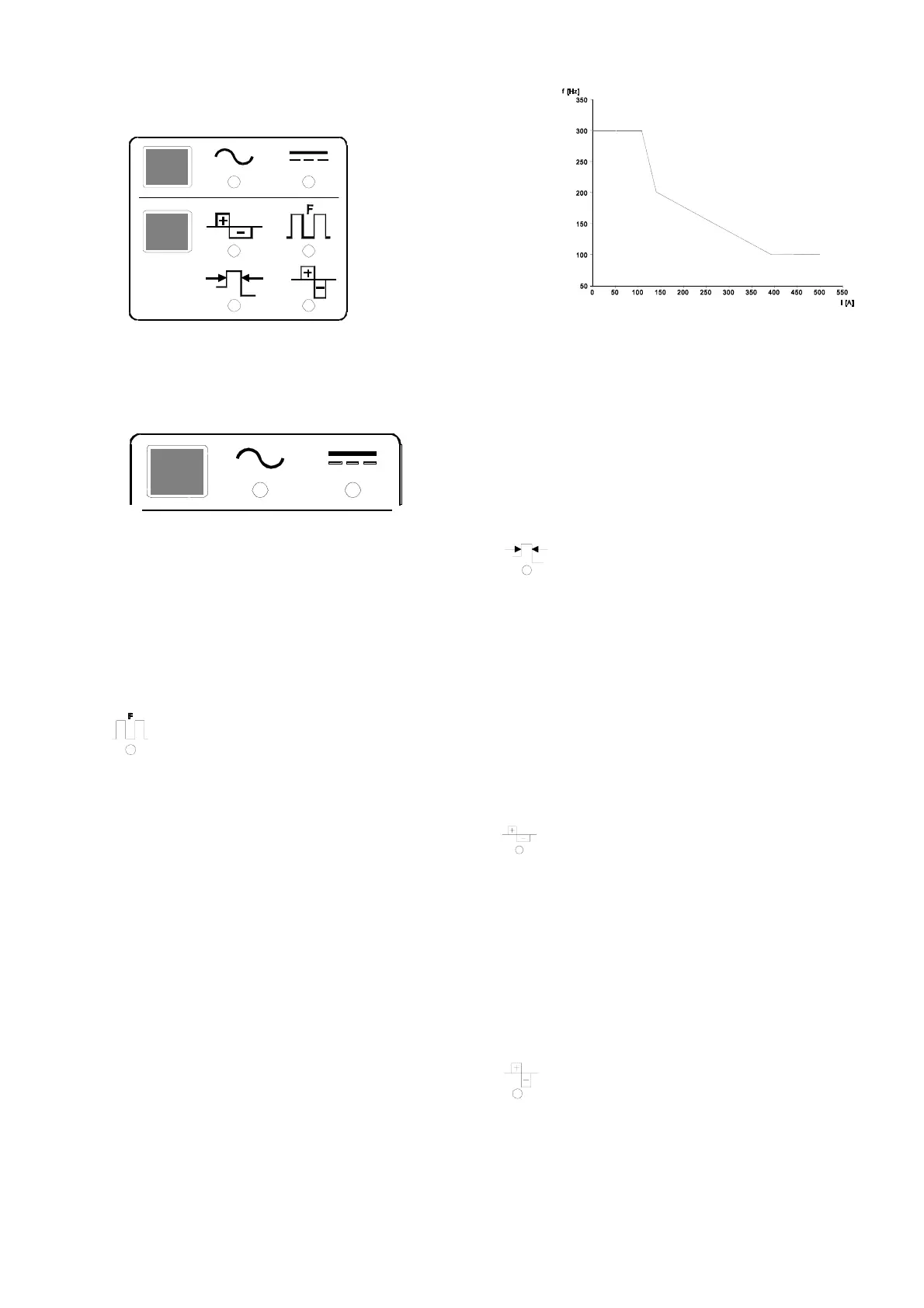

AC frequency

The AC frequency can be adjusted from 1 to

300 Hz for TIG welding and from 1 to 100 Hz

for MMA-welding. A low frequency during TIG welding

increases the tendency for the formation of a large

ball at the end of the tungsten electrode. This

tendency will be reduced by increasing the frequency.

Note 2: The AC frequency and welding current cannot be

adjusted to maximum simultaneously during TIG

welding - see illustration below. When the limit is

reached by adjusting the AC-frequency, the A-

lamp will illuminate in "units for parameter" and the

machine will reduce the AC frequency

automatically.

Note 3: If the frequency limit is exceeded by adjustment of

the welding current the AC frequency will be

reduced automatically (the indicator for AC

frequency flashes on and off for 5 sec.).

Note 4: If the pulse function is used during AC-welding the

AC frequency can be reduced in proportion to the

pulse times as the pulse frequency must be 5

times higher than the AC frequency. If the AC

frequency is to low the indicators for pulse times

will flash on and off for 5 seconds.

Note 5: Pulse adjustment error: If the pulse function is

used during AC-welding an automatic adjustment

of the pulse setting may occur. The indicators for

pulse times will then flash on and off for 5 se-

conds. The pulse times change automatically so

the pulse time and base time will be 0.03 seconds.

Electrode preheating (TIG)

On ignition of the AC TIG pilot arc the

tungsten electrode is preheated by a direct

current with positive polarity. Preheating of an

electrode is necessary before starting the AC welding

process. The length of the preheat period depends on

both the diameter of the electrode and the angle of

the point of the electrode, as well as the size of the

ball at the end of the electrode. Adjustment is possible

from -9 to +9, with -9 being the minimum and +9

being the maximum preheat periods. If the period is

too short the pilot arc will extinguish shortly after

ignition. The size of the ball at the end of the

electrode will increase if the pre-heat period is too

long.

AC-t-balance, based on time (TIG)

Adjustment of the refinement function during

the AC TIG welding of aluminium and its alloys. The

function is a balance based on time between the

positive and negative halfperiod.

Adjustment is possible between 1 and 100 per cent as

the statement in per cent is based on the negative

part of the period time. Adjustment continues until a

suitable refinement zone is established around the

molten pool. When MMA welding the balance can be

locked at 50 per cent which means that further

regulation is impossible.

AC-I-balance, based on current intensity

(TIG)

The purpose of the function is also adjustment

of the refinement zone during AC TIG welding.

Loading...

Loading...