Operators Manual

23

Travel speed is the rate at which the torch is being pushed or pulled along the weld joint.

For a xed heat seng, the faster the travel speed, the lower the penetraon and the

lower and narrower the nished weld bead. Likewise, the slower the travel speed, the

deeper the penetraon and the higher and wider the nished weld bead.

6.2 Types of welding beads

As you become more familiar with your new welder and beer at laying some simple

weld beads, you can begin to try some dierent weld bead types.

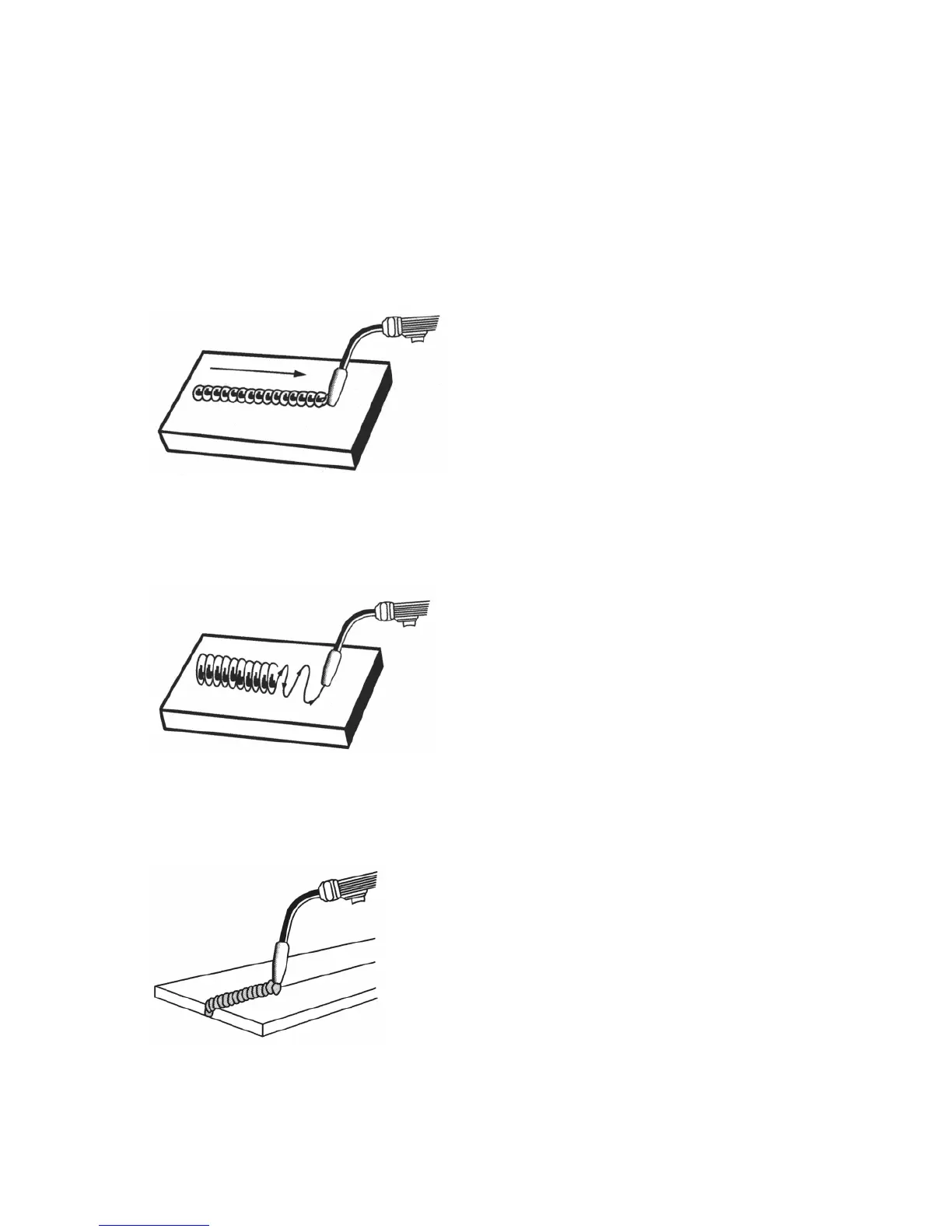

The STRINGER BEAD Is formed by traveling with the torch in a straight line while keeping

the wire and nozzle centered over the weld joint (See following gure).

The WEAVE BEAD Is used when you want to deposit metal over a wider space than would

be possible with a stringer bead. It is made by weaving from side to side while moving

with the torch. It is best to hesitate momentarily at each side before weaving back the

other way.

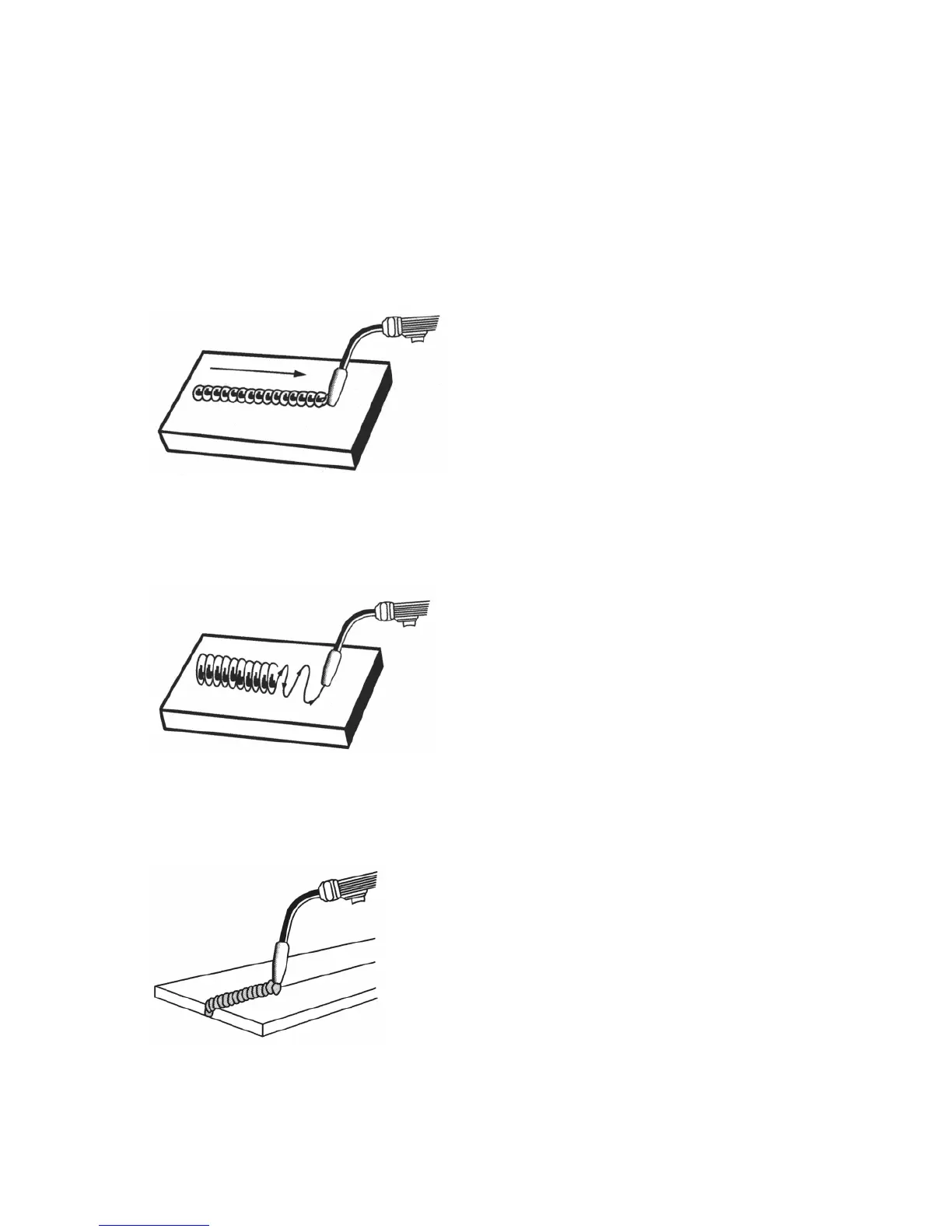

6.3 Welding posion

FLAT POSITION Is easiest of the welding posions and is most commonly used. It is best if

you can weld in the at posion if at all possible as good results are easier to achieve.

HORIZONTAL POSITION Is performed very much the same as the at weld except that

angle B (see HOLDING THE TORCH) is such that the wire, Directed more toward the metal

above the weld joint is to help prevent the weld puddle from running downward while

sll allowing slow enough travel speed.

Loading...

Loading...