Migomag SIM 200 LCD

Model No ASIM200LCD

22

5.3. Hold the torch in one hand, allowing the nozzle to rest on the edge of the work piece

farthest away from you, and at an angle similar to that which will be used when welding.

(See HOLDING THE TORCH if you are uncertain of the angle at which you will be welding).

5.4. With your free hand, turn the Wire Speed Dial to maximum and connue to hold

onto the knob.

5.5. Lower your welding helmet and pull the trigger on the torch to start an arc, then

begin to drag the torch toward you while simultaneously turning the Wire Speed Dial

counter-clockwise.

5.6. LISTEN! As you decrease the wire speed, the sound that the arc makes will change

from a spuering to a high-pitched buzzing sound and then will begin spuering again if

you decrease the wire speed too much. The point on the wire speed adjustment where

the high-pitched buzzing sound is achieved is the correct seng. You can use the wire

speed control to slightly increase or decrease the heat and penetraon for a given heat

seng by selecng higher or lower wire speed sengs. Repeat this tune-in procedure

if you select a new heat seng, a dierent diameter wire, or a dierent type of welding

wire.

6. Welding Techniques

WARNING:

EXPOSURE TO A WELDING ARC IS EXTREMELY HARMFUL TO THE EYES AND SKIN!

Prolonged exposure to the welding arc can cause blindness and burns. Never strike an arc

or begin welding unl you are adequately protected. Wear ameproof welding gloves, a

heavy long sleeved shirt, trousers with out cus, high topped shoes and an ANSI approved

welding helmet.

ELECTRIC SHOCK CAN KILL! To prevent ELECTRIC SHOCK, do not perform any welding

while standing, kneeling, or lying directly on the grounded work.

6.1 Moving the torch

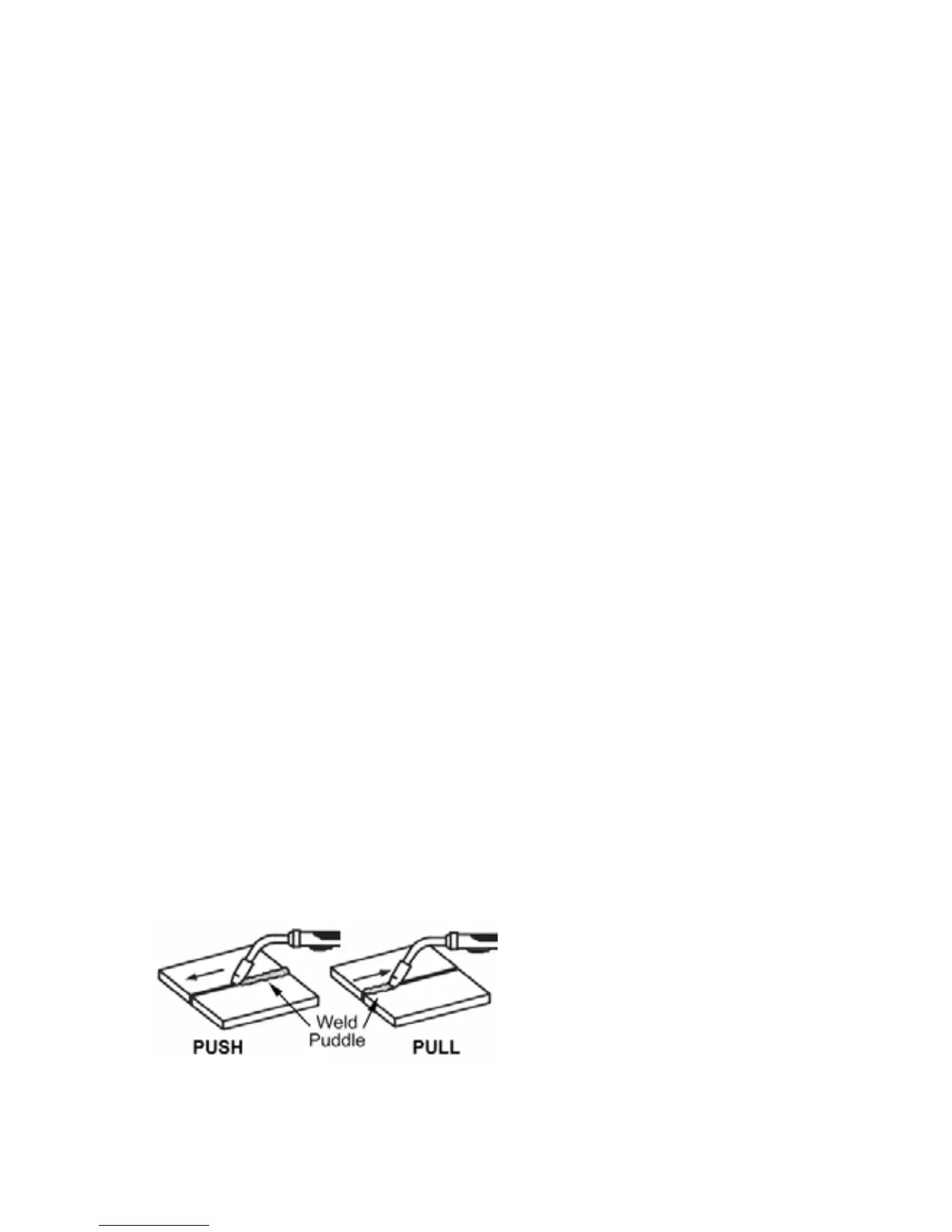

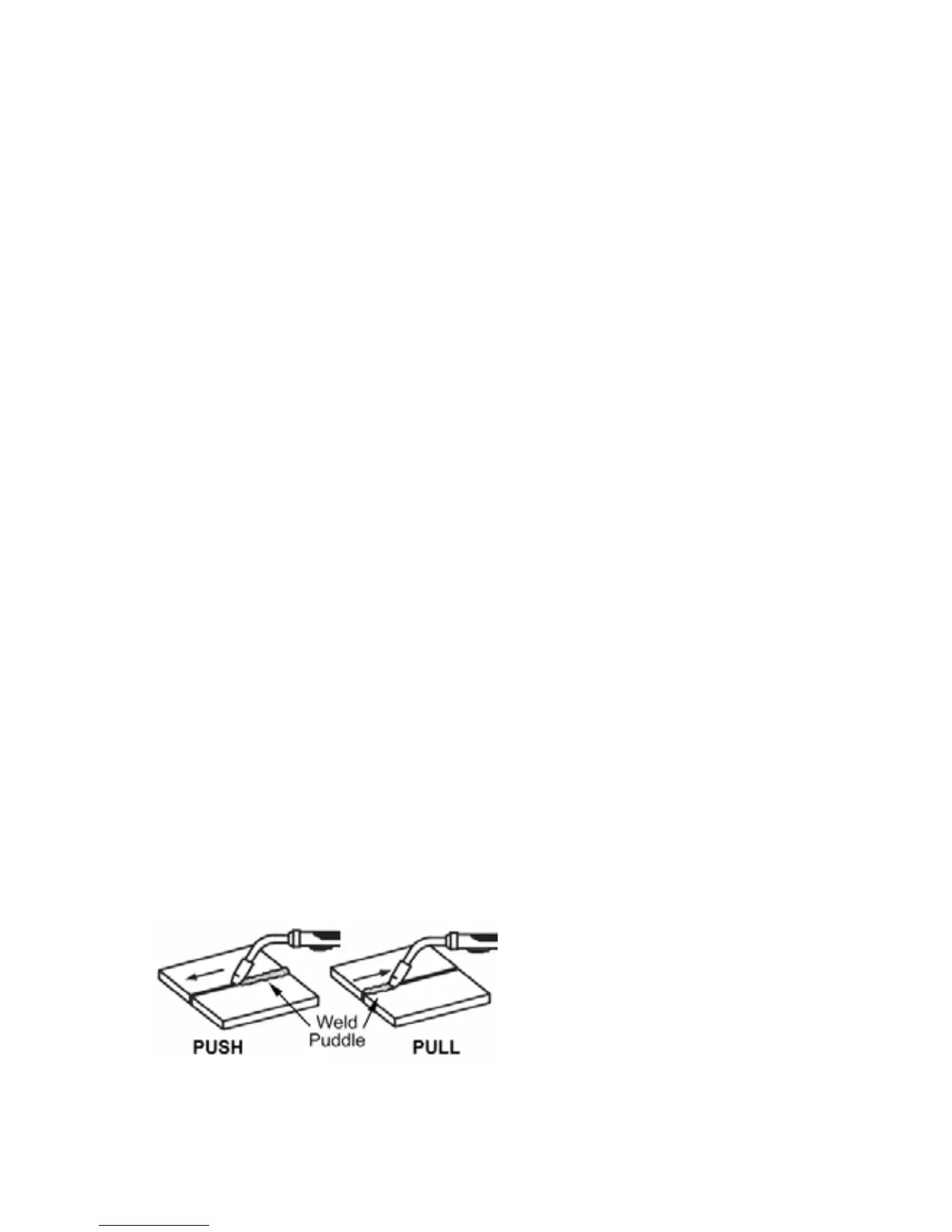

Torch travel refers to the movement of the torch along the weld joint and is broken into

two elements: Direcon and Speed. A solid weld bead requires that the welding torch be

moved steadily and at the right speed along the weld joint. Moving the torch too fast, too

slow, or erracally will prevent proper fusion or create a lumpy, uneven bead.

Travel direcon is the direcon the torch is moved along the weld joint in relaon to the

weld puddle. The torch is either PUSHED into the weld puddle or PULLED away from the

weld puddle.

For most welding jobs you will pull the torch along the weld joint to take advantage of the

greater weld puddle visibility.

Loading...

Loading...