Operators Manual

25

NOTE:

WHEN USING SELF-SHIELDING FLUX-CORE WIRE it is very important to thoroughly chip

and brush the slag o each completed weld bead before making another pass or the next

pass will be of poor quality.

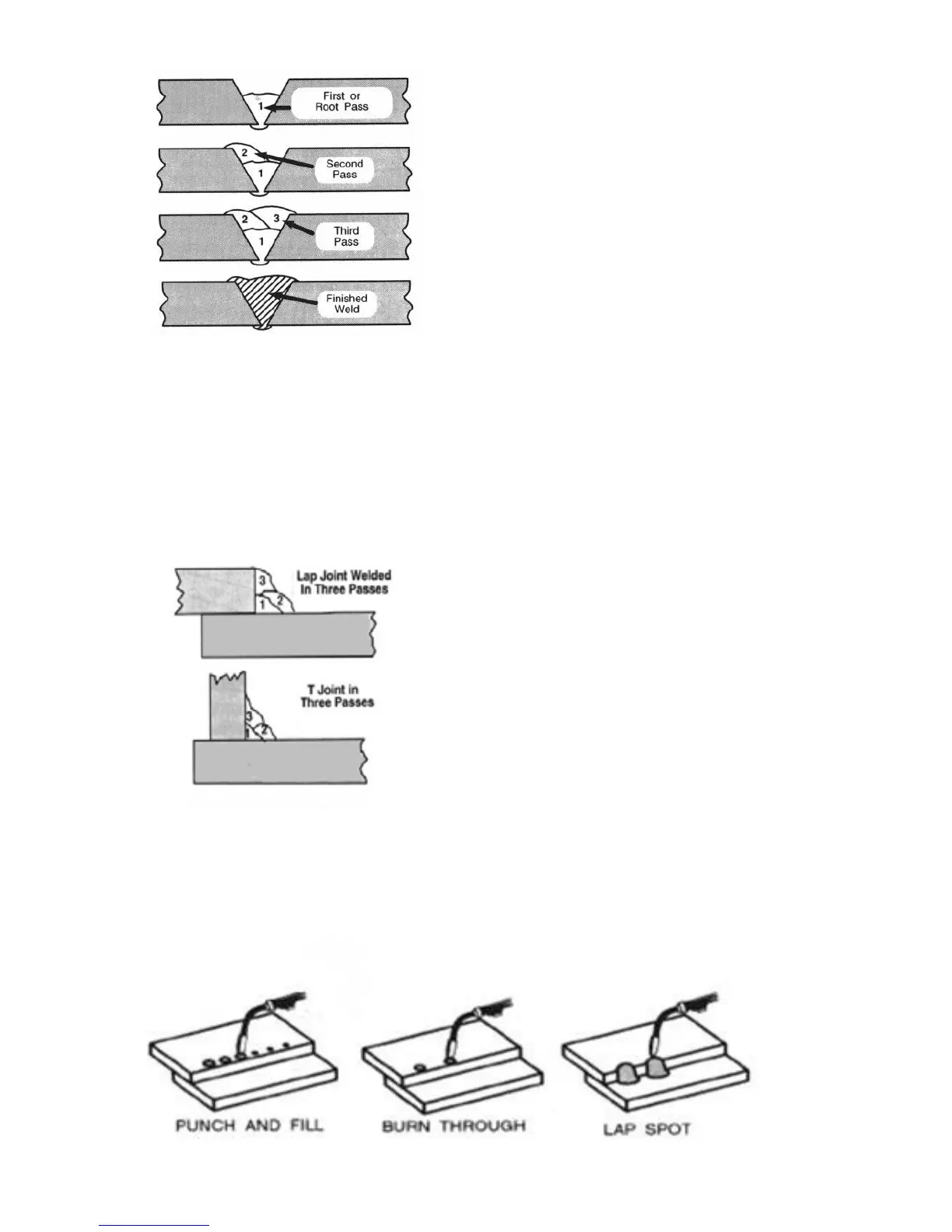

Fillet Weld Joints. Most llet weld joints, on metals of moderate to heavy thickness, will

require mulple pass welds to produce strong joint. The illustraons in Figure 19 show the

sequence of laying mulple pass beads into a T llet joint and a lap llet joint.

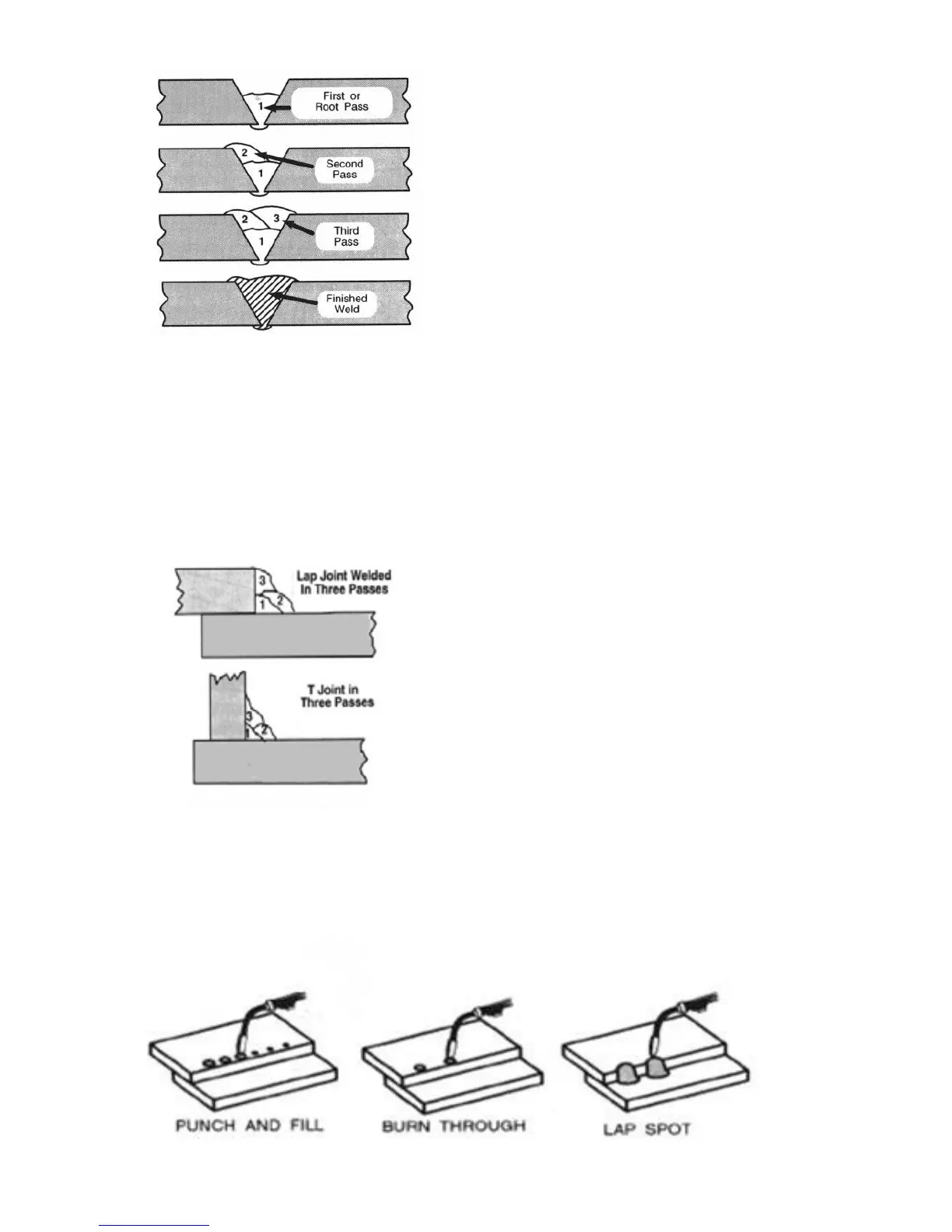

6.5 Spot welding

There are three methods of spot welding: Burn-Through, Punch and Fill, and Lap. Each has

advantages and disadvantages depending on the specic applicaon as well as personal

preference.

Loading...

Loading...