Migomag SIM 200 LCD

Model No ASIM200LCD

28

2. Welding Techniques

The best way to teach yourself how to weld is with short periods of pracce at regular

intervals. All pracce welds should be done on scrap metal that can be discarded. Do not

aempt to make any repairs on valuable equipment unl you have sased yourself that

your pracce welds are of good appearance and free of slag or gas inclusions.

2.1 Holding the electrode

The best way to grip the electrode holder is the way that feels most comfortable to

you. To Posion the Electrode to the work piece when striking the inial arc it may be

necessary to hold the electrode perpendicular to the work piece. Once the arc is started

the angle of the electrode in relaon to the work piece should be between 10 and 30

degrees. This will allow for good penetraon, with minimal spaer.

2.2 Striking the arc

WARNING:

EXPOSURE TO A WELDING ARC IS EXTREMELY HARMFUL TO THE EYES AND SKIN.

• Never strike an arc or begin welding unl you have adequate protecon

• Wear ameproof welding gloves, heavy long-sleeved shirt, cuess trousers, high-

topped shoes and a welding helmet or shield

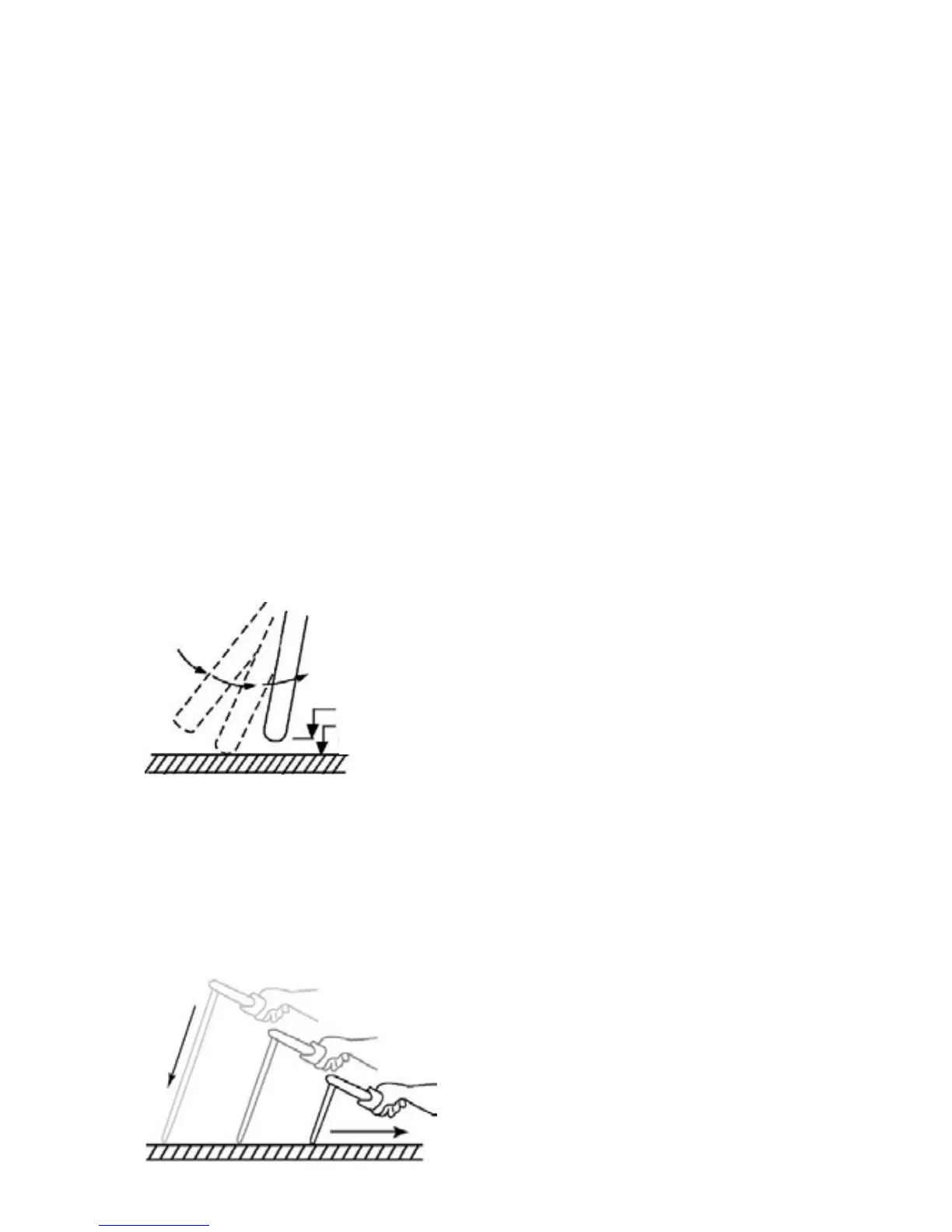

Scratch the work piece with the end of electrode to start arc and then raise it quickly

about 1/8 inch gap between the rod and the work piece. See following picture:

It is important that the gap be maintained during the welding process and it should be

neither too wide or too narrow. If too narrow, the rod will sck to the work piece. If too

wide, the arc will be exnguished. It needs much pracce to maintain the gap. Beginners

may get scking or arc exnguishing. When the rod scks to the work piece, gently rock it

back and forth to separate them. If not, the circuit is short connecon,

and it will overload the welder. A good arc is accompanied by a crisp, cracking sound. The

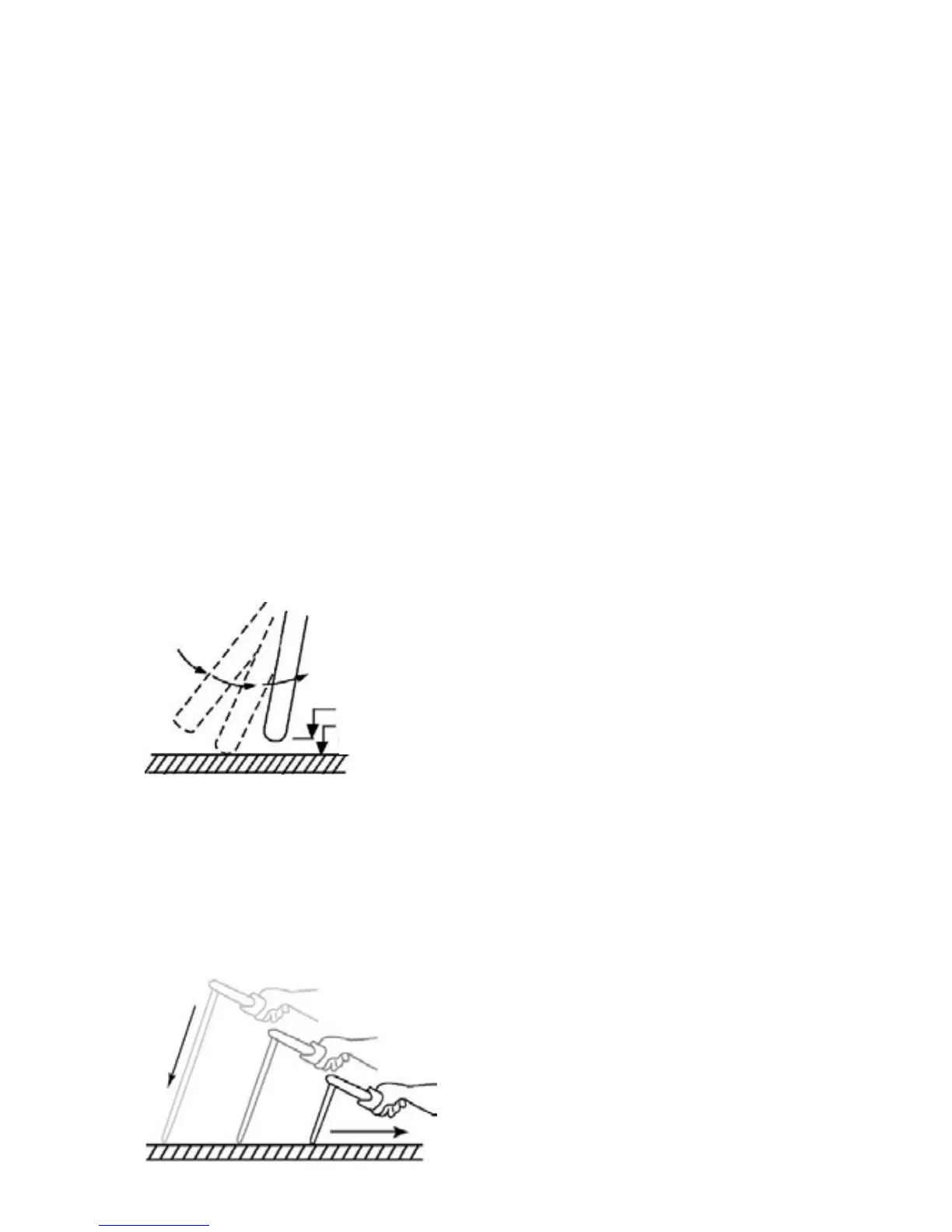

sound is similar to that made by eggs frying. To lay a weld bead, only 2 movements are

required; downward and in the direcon the weld is to be laid, as in following gure:

3.2mm

Loading...

Loading...